Automatic polishing machine with quartz furnace tube and polishing method

An automatic polishing and polishing machine technology, used in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of difficulty in ensuring product processing consistency, high labor intensity, etc., to improve production efficiency and production quality control level. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

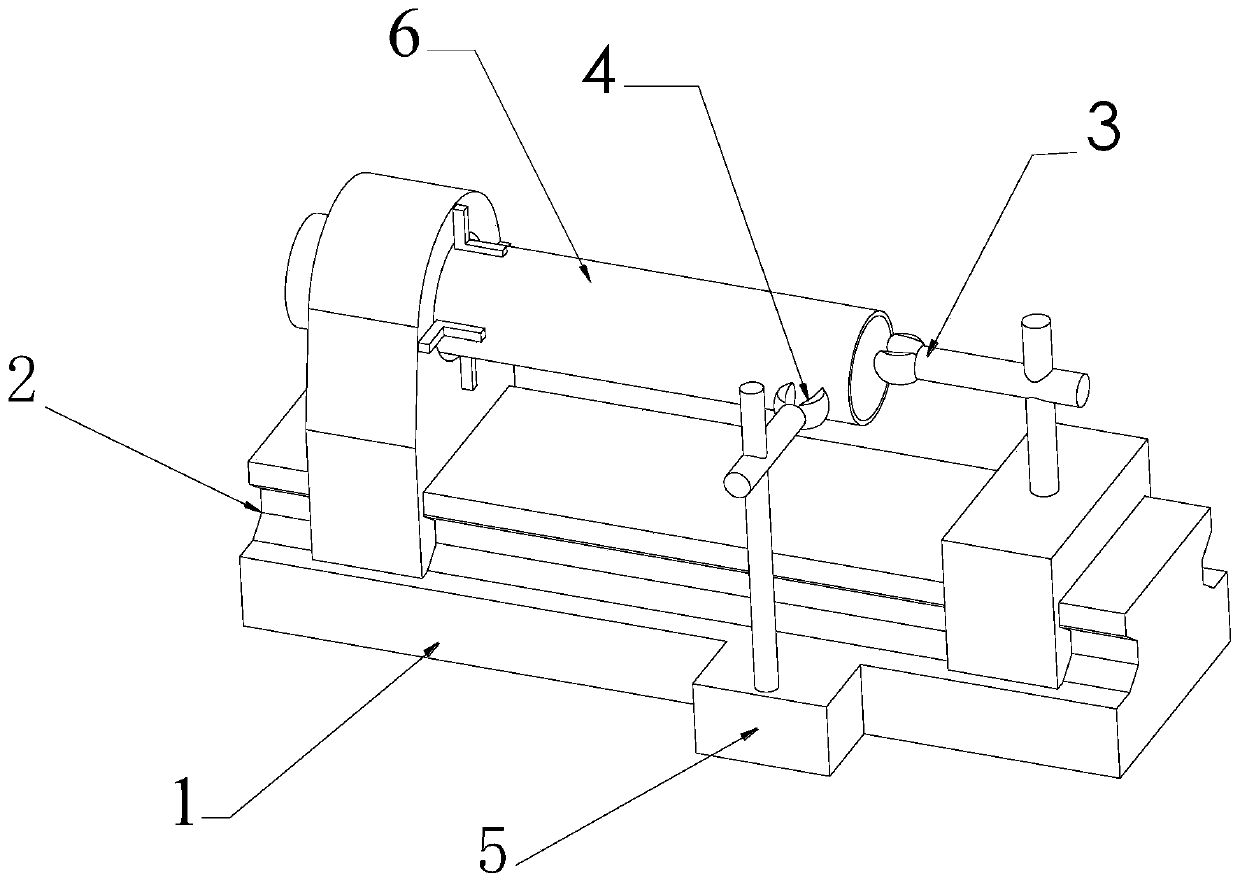

[0017] According to one or more embodiments, such as figure 1 As shown, a quartz furnace tube automatic polishing machine has: a quartz furnace tube; a machine table, which is the base of the entire polishing machine; a first guide rail, which is installed on the upper surface of the machine table; a second guide rail, which is installed on the machine Table side surface; Inner flame gun frame, for installing inner flame gun, said inner flame gun frame is installed on the first guide rail by slide block, and inner flame gun frame is positioned on the axis of quartz furnace tube, makes inner flame gun can Move along the first guide rail to flame polish the inner surface of the quartz furnace tube; the outer flame gun frame is used to install the outer flame gun, and the outer flame gun frame is installed on the second guide rail through a slider, so that the outer flame gun can be installed along the Moving along the second guide rail, the outer surface of the quartz furnace tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com