A method to improve the fire resistance of reinforced concrete beams strengthened by embedded composite bars

A reinforced concrete beam and embedded technology, which is applied in fire protection, construction, building maintenance, etc., can solve the problems of insufficient fire resistance of reinforced concrete beams reinforced by embedded composite bars, so as to avoid high loss of materials, good high temperature resistance, and energy saving The effect of material usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

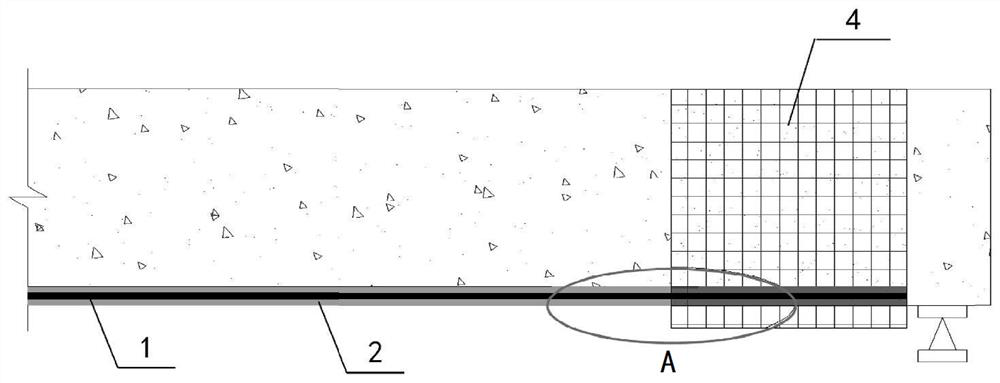

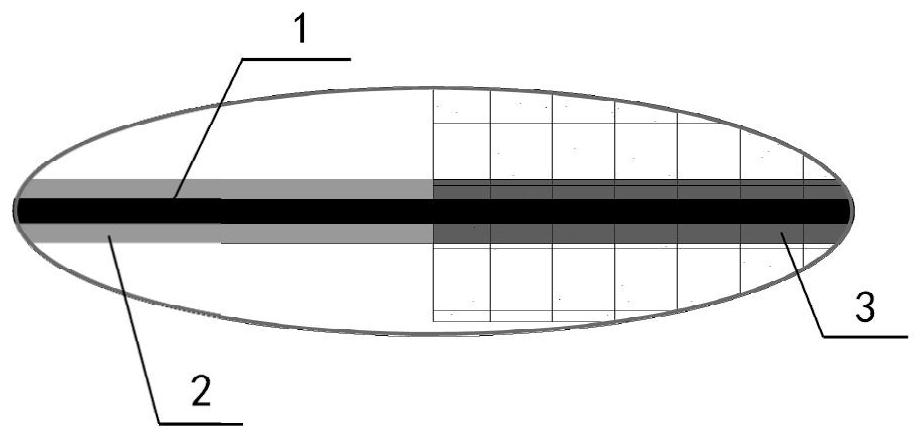

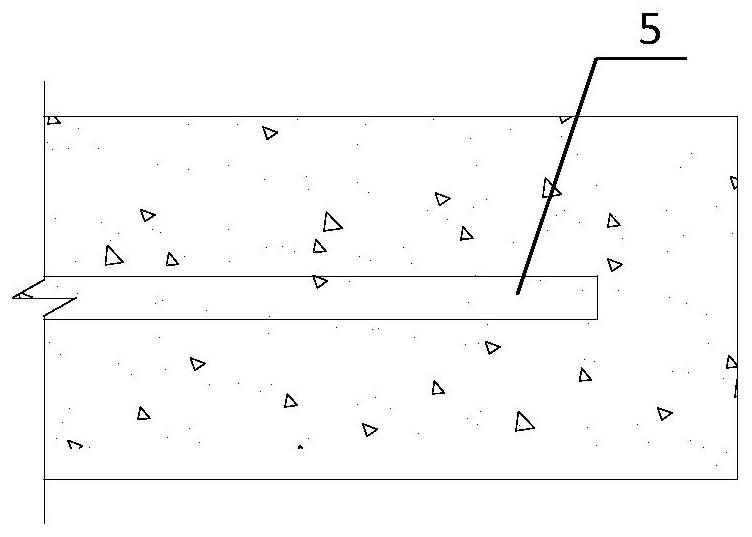

[0032] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] A method for improving the fire resistance of reinforced concrete beams reinforced with composite bars embedded in an embodiment of the present invention includes the following steps:

[0034] Step 10) Grooving is made in the tensile zone at the bottom of the reinforced concrete beam to form a channel.

[0035] Step 20) Fill the channel with organic rebar glue and inorganic fiber mortar to form a bonding material layer; wherein, the organic rebar glue is located at both ends of the channel, the inorganic fiber mortar is located in the middle of the channel, and the organic rebar is located at the middle of the channel. There is a gap between the organic rebar glue layer formed by the glue and the inorganic fiber mortar layer formed by the inorganic fiber mortar. Preferably, the gap is 5-15 cm.

[0036] Step 30) Put the composite ten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com