Low-angle dip stratified rock mass misfire-detonation-preventing blasting method

A gentle inclination, layered technology, applied in blasting and other directions, can solve problems such as high block rate, potential safety hazards, over-under-digging, etc., to achieve the effects of simple operation, improved safety, and reduced mutual misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

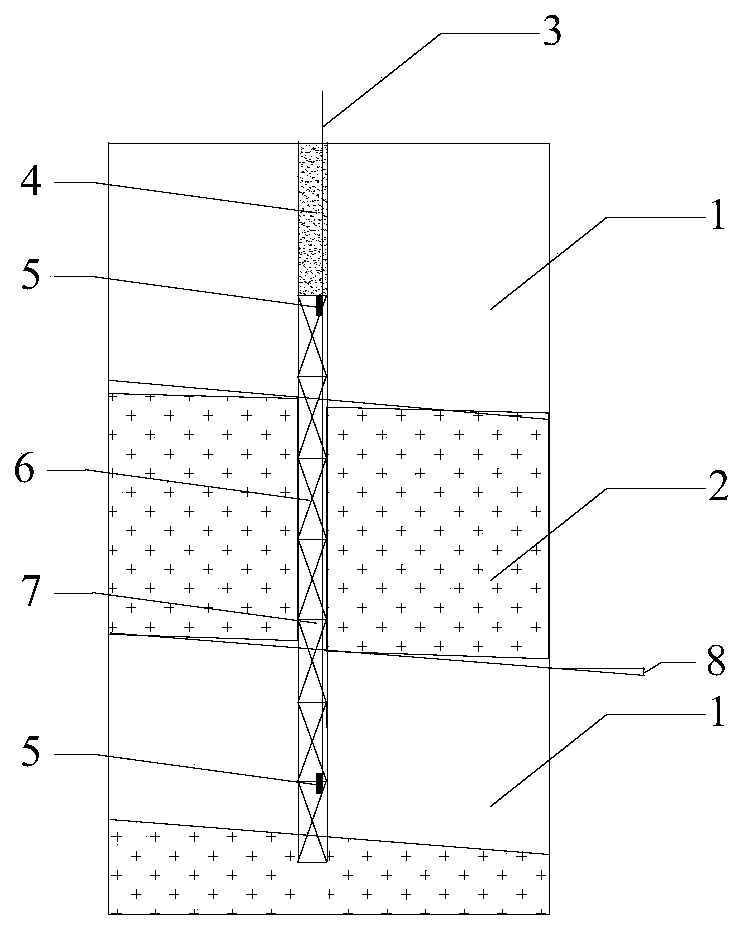

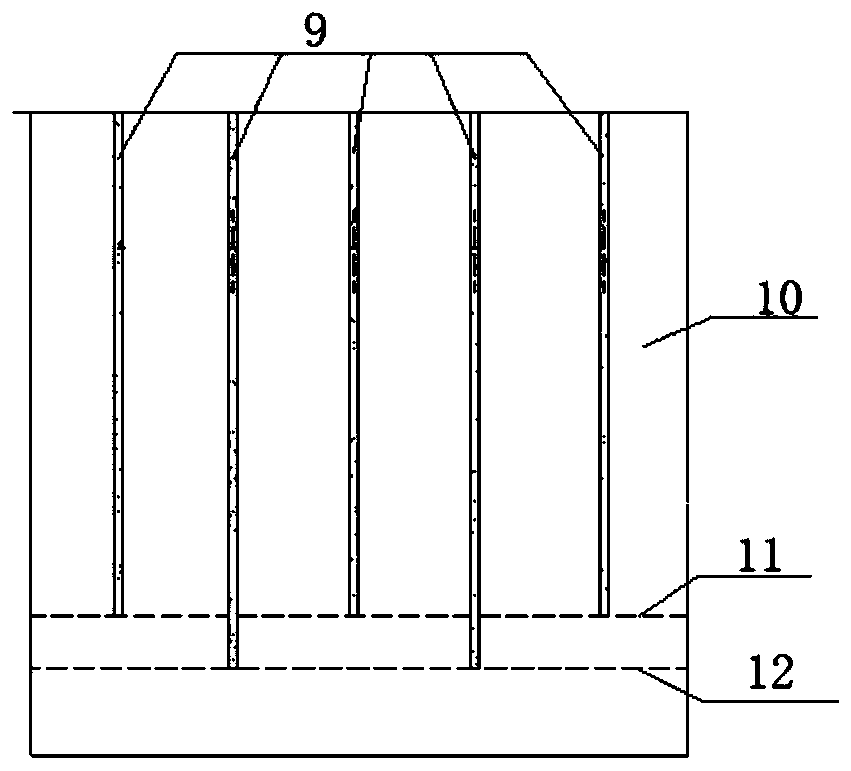

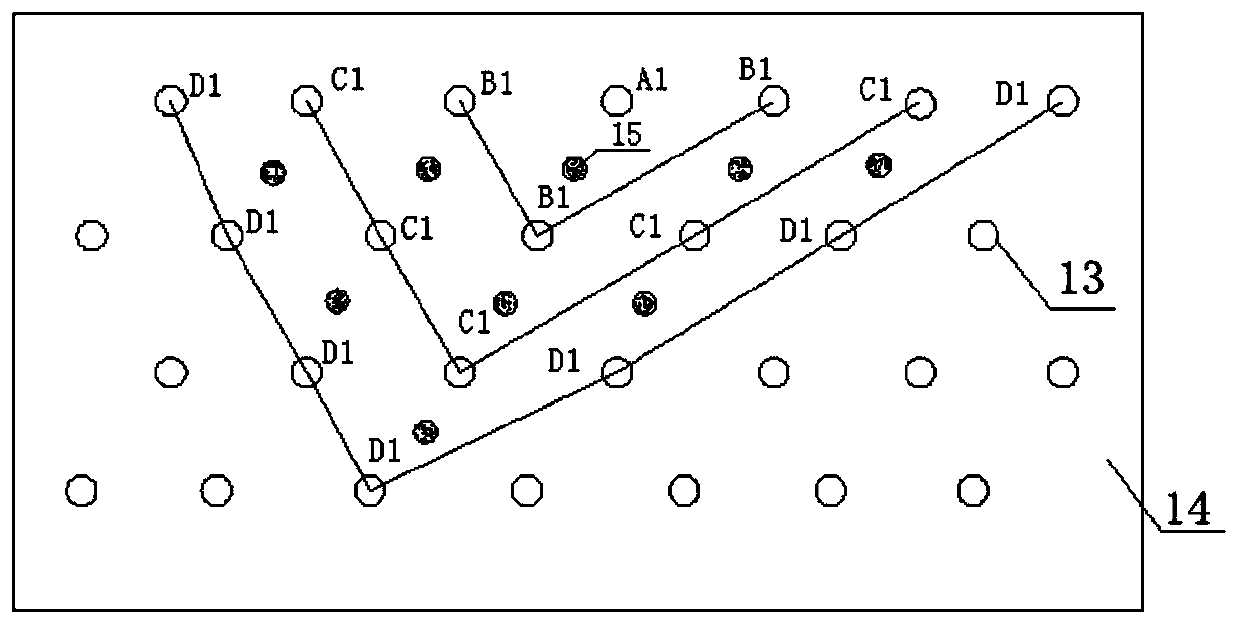

[0027] Below by embodiment, in conjunction with accompanying drawing, technical scheme of the present invention is described further in detail:

[0028] The floor of a water cushion pond downstream of a high arch dam was excavated. The lithology of the water cushion pond floor is columnar joint basalt, with well-developed joint surfaces, and part of it is breccia lava. At 2.0m-4.0m and 5.5m-6.0m of the rock mass, there are hard breccia lavas with a thickness of about 2.0m and a thickness of about 0.5m. The rock quality of this rock formation is complete and hard. Blasting hole diameter is 76mm, blasting hole depth is 6.0 / 5.5m, plugging length is 1.0m, hole spacing is 1.0m, row spacing is 1.0m, Φ32 2# rock emulsion explosive is used, charge is not coupled, and the coil density is 0.95~1.30g / cm 3 , Sacrifice explosion distance 4cm. Specifically include the following steps:

[0029] 1. According to the previous geological exploration data, it is determined that there is a lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com