Semi-automatic device for combining bulk optical fibers at optical cable end socket into belt fiber and belt-combining method

A semi-automatic, optical fiber technology, applied in the field of optical fiber communication, can solve the problems of inappropriate fixtures and equipment, etc., and achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

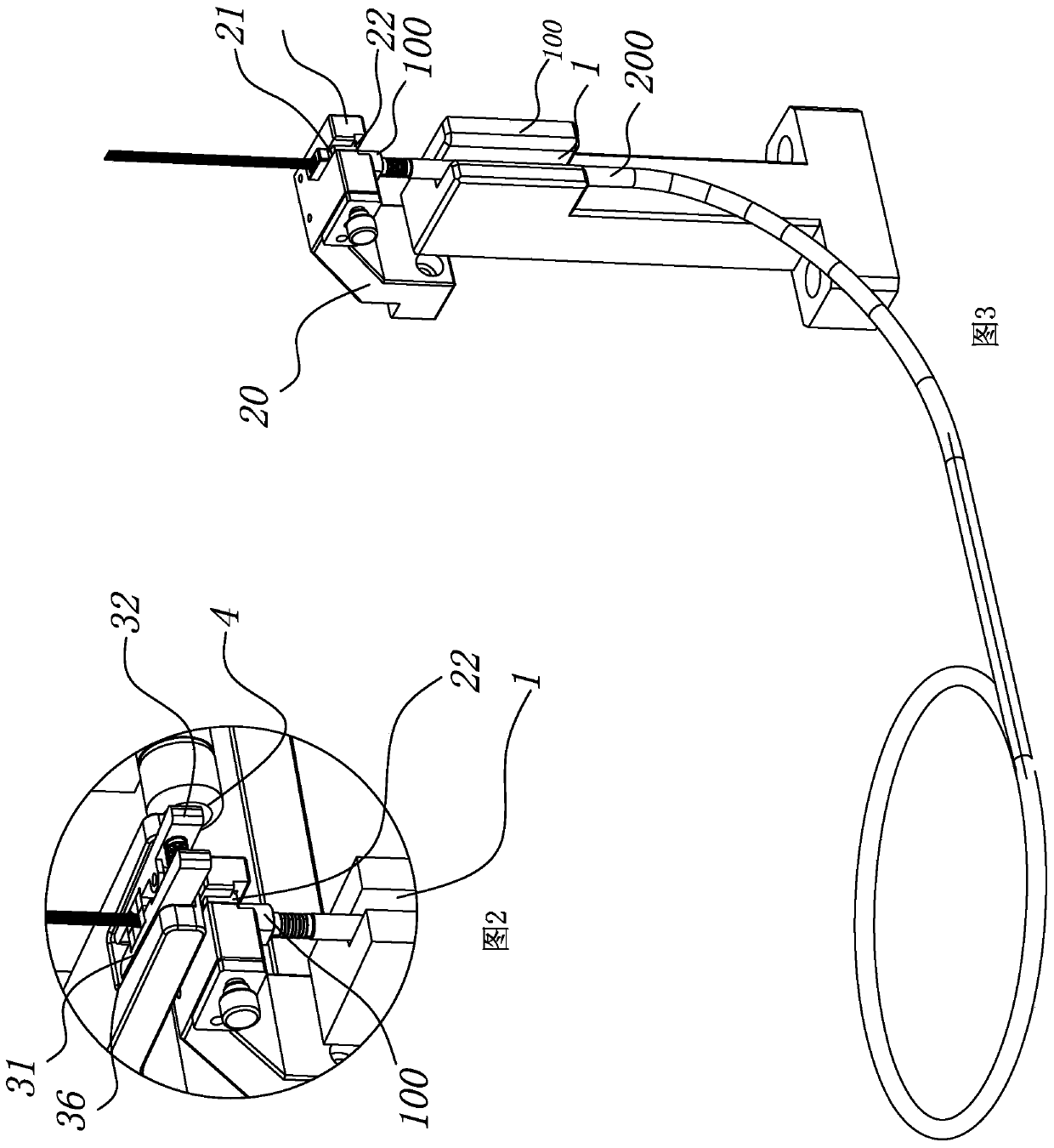

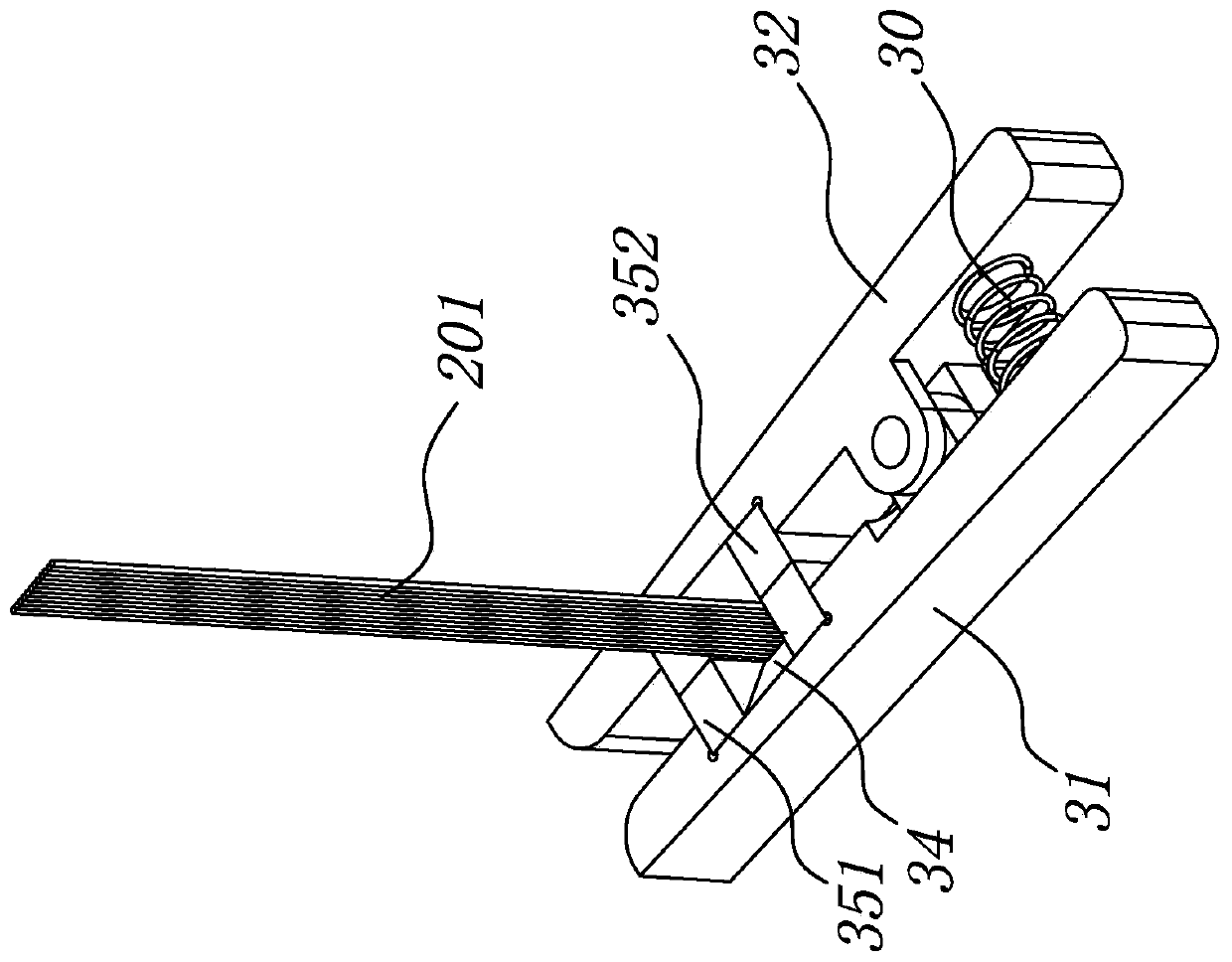

[0031] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings. The drawings are provided for the purpose of illustrating the embodiments and are not intended to limit the scope of the invention. In the drawings, the same reference numerals denote the same components, and description thereof may not be repeated. The dimensional ratios of the drawings are not necessarily exact.

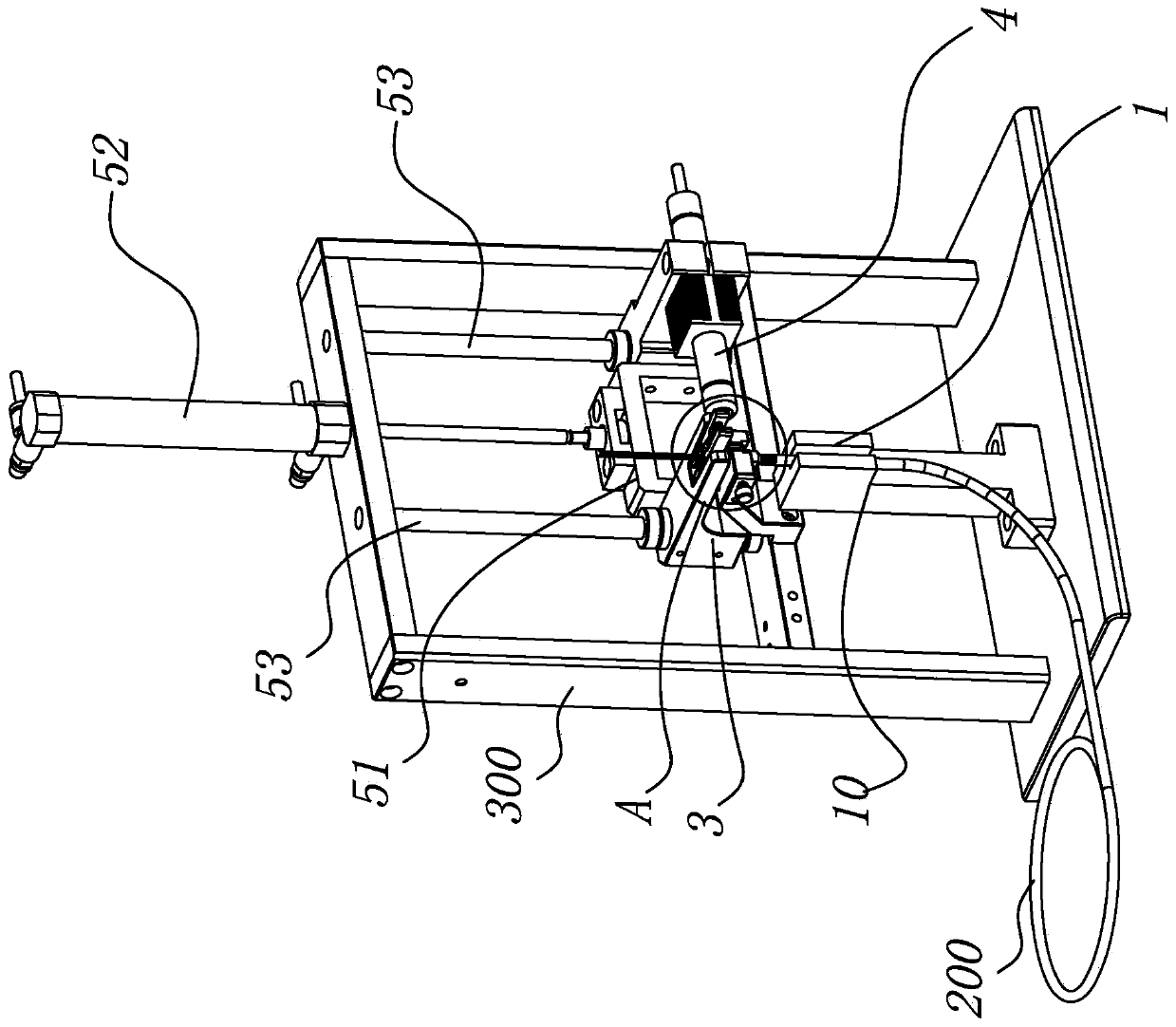

[0032] The invention provides a semi-automatic device for dispersing optical fibers at the end of an optical cable and forming a ribbon fiber, comprising an optical cable guiding and positioning component, a body fixing component, an optical fiber positioning, guiding and fixing component, a UV light source and a lifting component.

[0033] The optical cable guiding and positioning part 10 is installed on the fixing frame 300 of the device, and is located below the body fixing assembly, and is used for guiding and positioning the optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com