A ship diesel engine abrasive particle type identification method based on information fusion

A marine diesel engine and identification method technology, which is applied in the field of safe operation and maintenance of marine diesel engines, can solve problems such as uncertain information or limited multi-information processing capabilities, model failure, and inaccurate identification results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

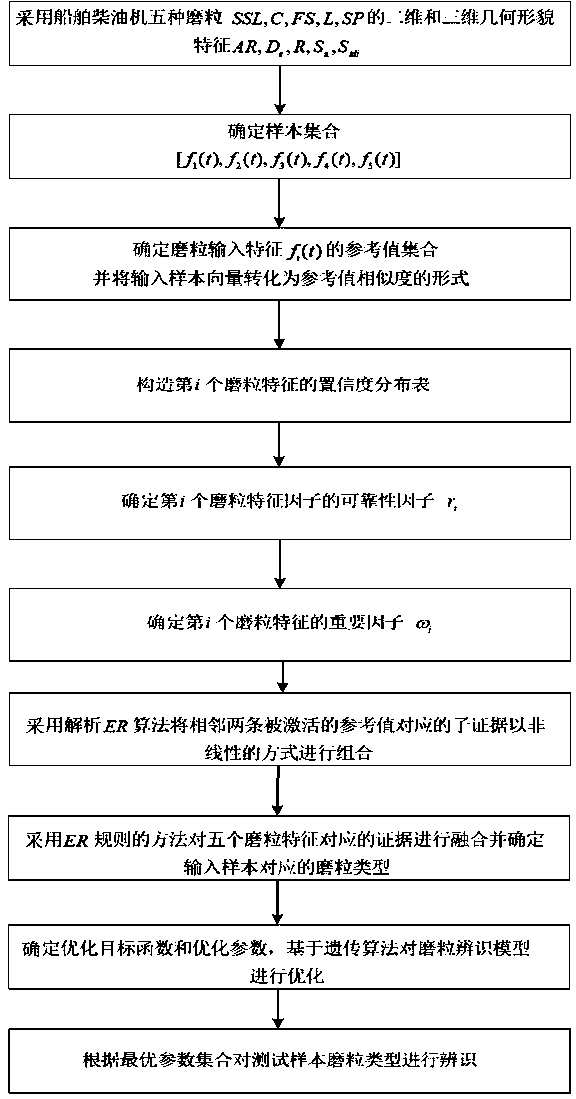

[0051] The present invention proposes a method for identifying the type of wear particles in marine diesel engines based on information fusion, the process of which is as follows figure 1 shown, including the following steps:

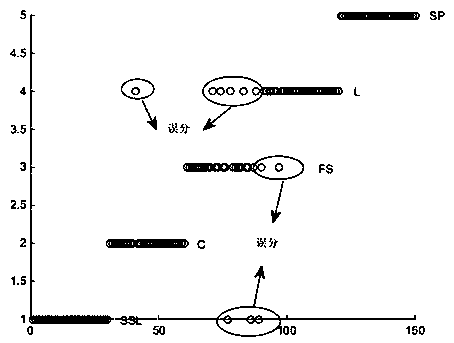

[0052] (1) Oil samples were collected from the online oil monitoring system of medium-speed diesel engines, and the types of abrasive particles in the oil samples were divided into (severe sliding wear abrasive particles) SSL, (cutting abrasive particles) C, (fatigue massive abrasive particles) FS , (layered abrasive grains) L, (spherical abrasive grains) SP, these five types of abrasive grains constitute the identification framework of the model, denoted as Y, Y = [SSL, C, FS, L, SP].

[0053] (2) For the multiple oil samples collected, filter membrane spectrograms were made and photographed, and the two-dimensional geometric features of the abrasive grains in the oil samples were extracted from the abrasive grain pictures: body ratio (AR), equivalent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com