Device and method for joint calibration of industrial binocular camera and infrared thermal imager

A technology of infrared thermal imager and binocular camera, which is applied in the fields of instruments, image analysis, image data processing, etc., and can solve problems such as high cost and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

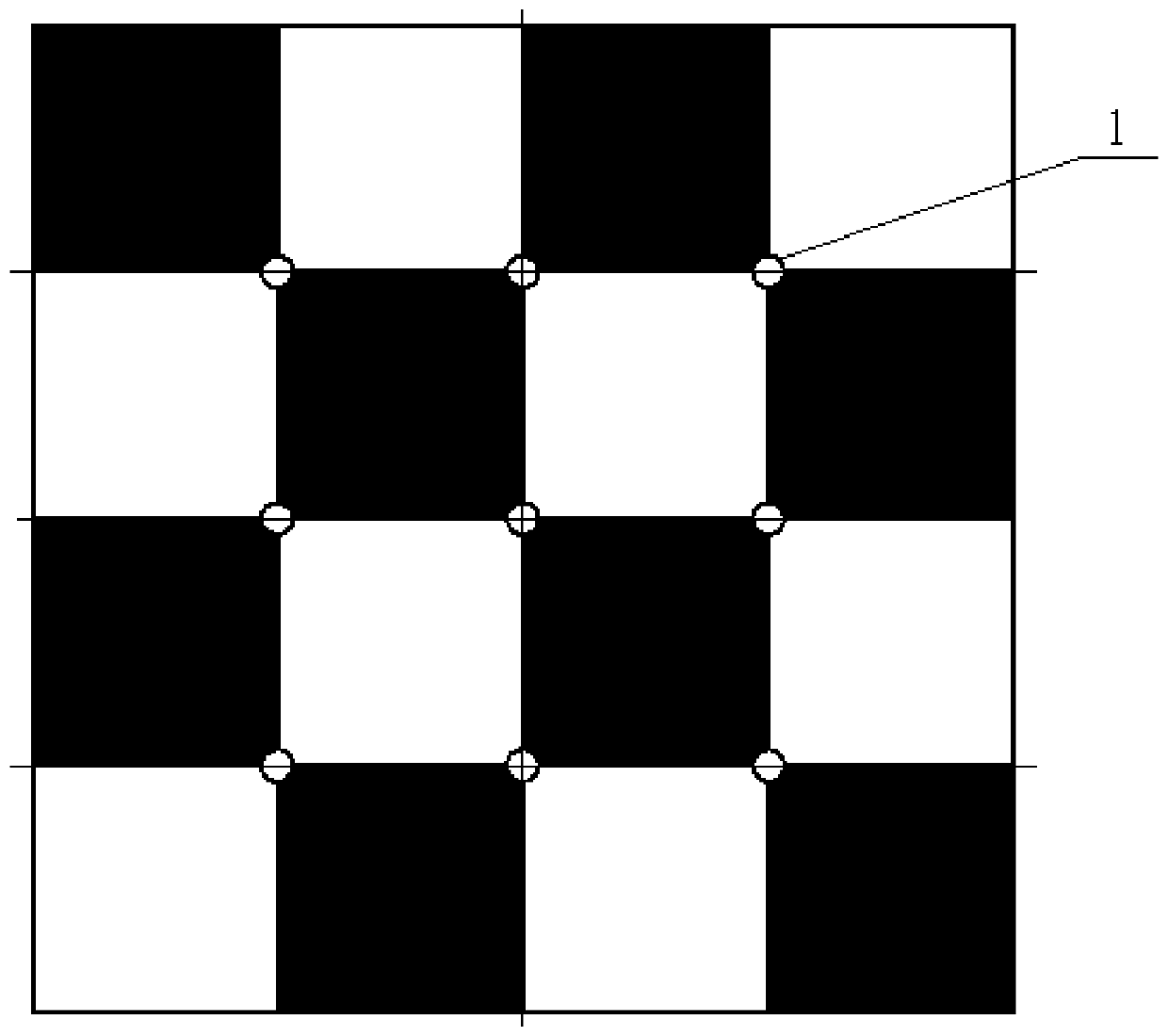

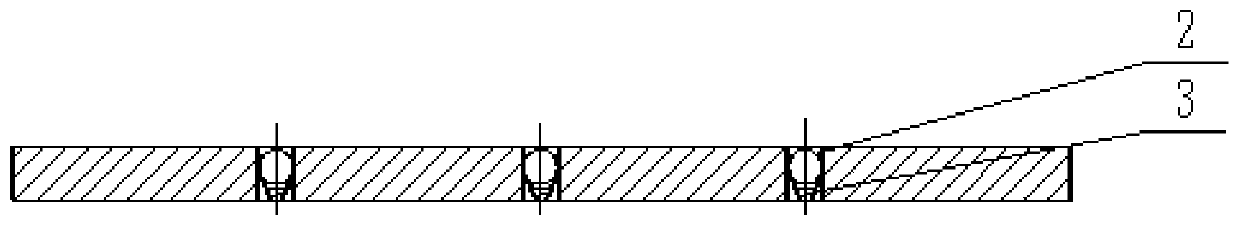

[0080] Such as figure 1 As shown, the present invention includes the following feature parts: 1 is a small hole, 2 is an incandescent bulb, and 3 is a lamp holder.

[0081] A device for joint calibration of an industrial binocular camera and an infrared thermal imager according to the present invention uses the inner corner point of the Zhang Zhengyou calibration plate in a standard format as the center of the circle, and opens a small hole, the radius of which is less than half of the side length of the black and white grid;

[0082] An incandescent bulb is installed in the small hole, and the base of the incandescent bulb communicates with the power supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com