A kind of reactor for dehydrogenation reaction and its preparation method and application

A reactor and reaction technology, applied in the direction of chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problems of expensive palladium metal, high cost, etc., achieve high adsorption storage, reduce reaction temperature, improve conversion efficiency and selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

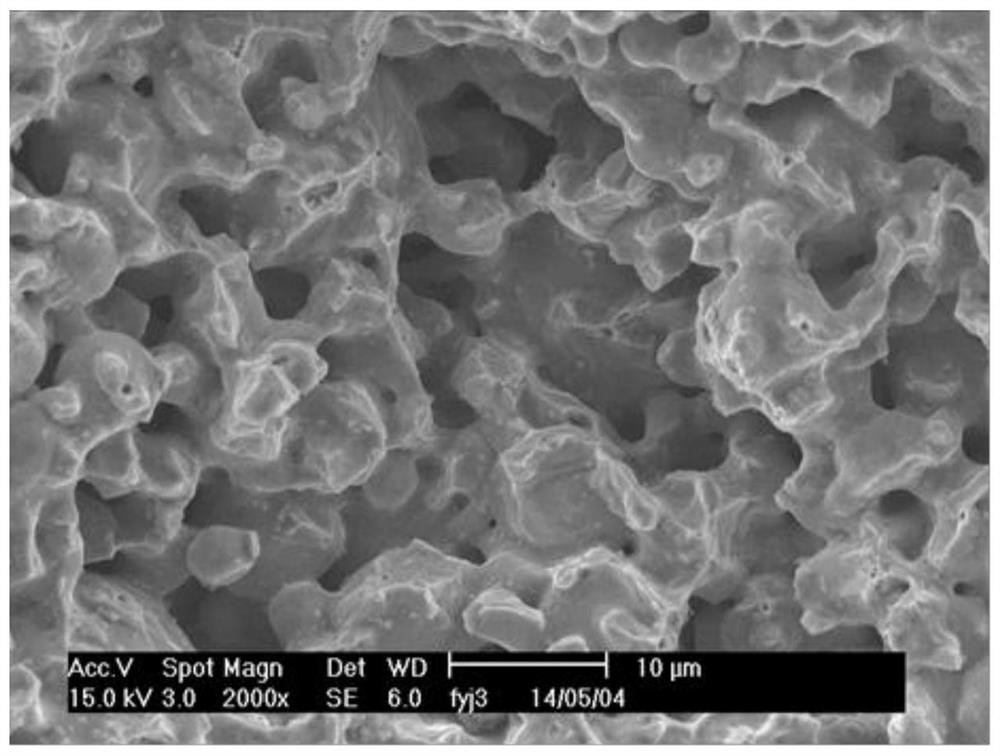

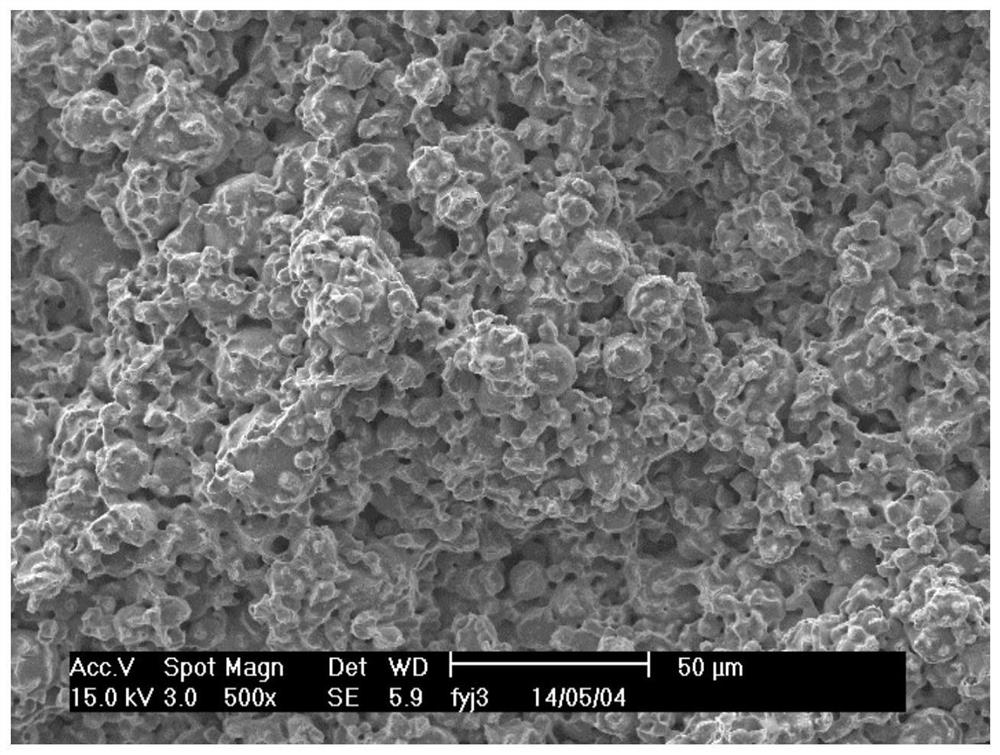

[0037] Preparation of metal organic skeleton material: 0.5 g (1.68 mmol) Zn in the beaker (NO 3 ) 2 · 6h 2O and 1 g (12 mmol) 2-methylimidazole (2-methylimidazole) were dissolved in a mixed solution consisting of 50 ml of deionized water and 50 mL of methanol. The beaker was placed in an ultrasonic instrument, 80 ° C, ultrasonic 24h, then washed with methanol and dried at 80 ° C for 3 h to prepare ZnO-MOFs.

[0038] Pre-treatment of porous metal pipe: 316L porous stainless steel pipe (outer diameter 10mm, wall thickness 1 mm, 35% average pore size, 35% porosity, wire cutting process of 2 cm long), sequentially with sodium hydroxide solution and dilute nitric acid solution Clean and washed with deionized water, and finally washed with anhydrous ethanol, and the spare was dried.

[0039] 2 g of ZnO-mofs was dissolved in 10 ml of water into a ZnO-MOFS slurry, and the pretreated porous stainless steel tube was immersed in the ZnO-MOFS slurry, and the reactive reactive for dehydrogenat...

Embodiment 2

[0041] Pretreatment of a porous metal tube is in Example 1.

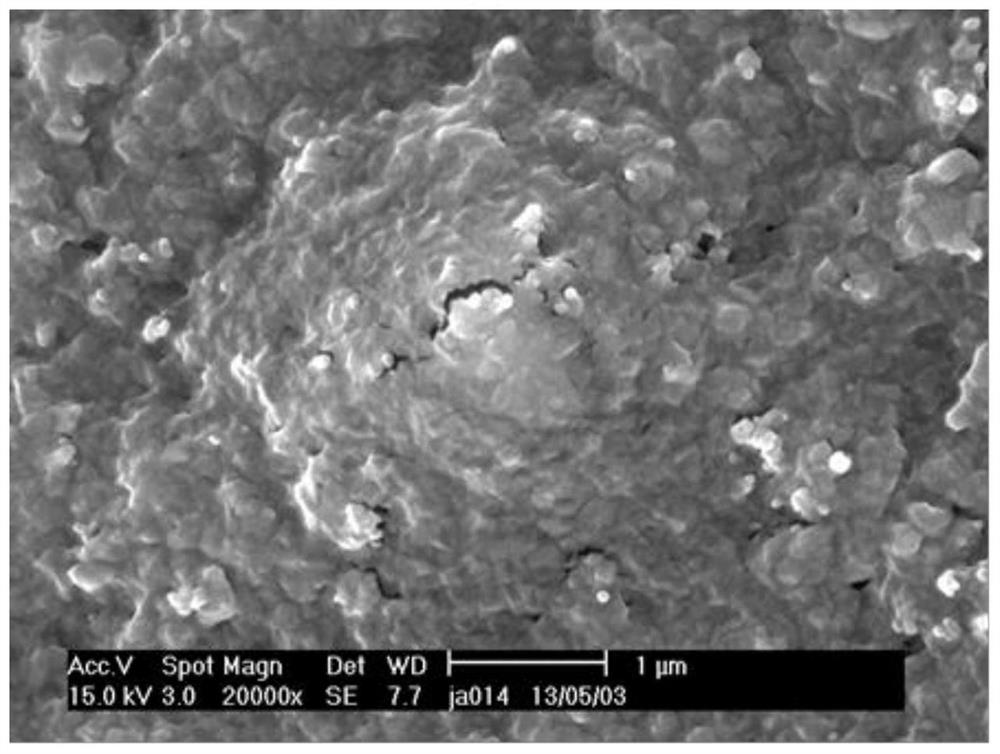

[0042] A 15 ml of 0.1 M nitrate solution and 15 ml of 0.1 M hexamethylene tetraamine solution, respectively, mixed the nitrate solution and the hexamethylene tetraamine solution and transfer the formed mixed liquid into the water heater, and the pre-treatment The porous stainless steel tube is inserted into the mixture, and the hot reaction is 2 hours at 95 ° C, taken out, and naturally drying the surface-growing porous stainless steel tube. The quality of the porous metal tube before and after the reaction can be obtained, and the mass of zinc oxide nanorod array grown in the surface of the porous stainless steel pipe can be obtained.

[0043] 0.2 g (2.4 mmol) 2-methylimidazole (2-methylimidazole) was dissolved in 25 ml dimethylformamide (DMF) solution, and in the polytetrafluoroethylene hydraulic, the surface growth has zinc oxide. The porous stainless steel pipe of the nano-bar array (wherein zinc oxide 0.05 g) is pl...

Embodiment 3

[0045] The two ends of the reactor obtained for the dehydrogenation reaction prepared in Example 1 were received together with a stainless steel tube of the outer diameter of 10 mm, and the wall thickness of 1 mm, as a reactor of propane dehydrogenation catalytic reactions. The 0.5 g of Pt catalyst was added to the start of the reaction, and the Pt catalyst was pretreated. The pretreatment conditions were heated to 300 to 600 ° C at a temperature rise rate of 5 ° C / min, and preprocessing for 2 hours in a hydrogen atmosphere. Thereafter, heated to the reaction temperature in a hydrogen atmosphere, and a raw material gas was added, and the normal pressure reaction was added. Raw gas ratio C 3 Hide 8 : H 2 = 1: 4 (volume ratio), propane liquid spills of 3.0 h -1 , Propane dehydrogenation reaction temperature: 600 ° C, when the catalyst index reaches a steady state, propane conversion data 37%, propylene selectivity 95.5%, one-way yield of 36%, Figure 4 Indicated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com