Combined sorting device and combined sorting machine

A sorting device and sorting machine technology, which is applied in the field of sorting machines, can solve the problems of trouble, unsatisfactory sorting effect, and splicing of multiple check-type sorting machines in series, so as to improve sorting efficiency and improve sorting efficiency. Select the effect, easy to assemble the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

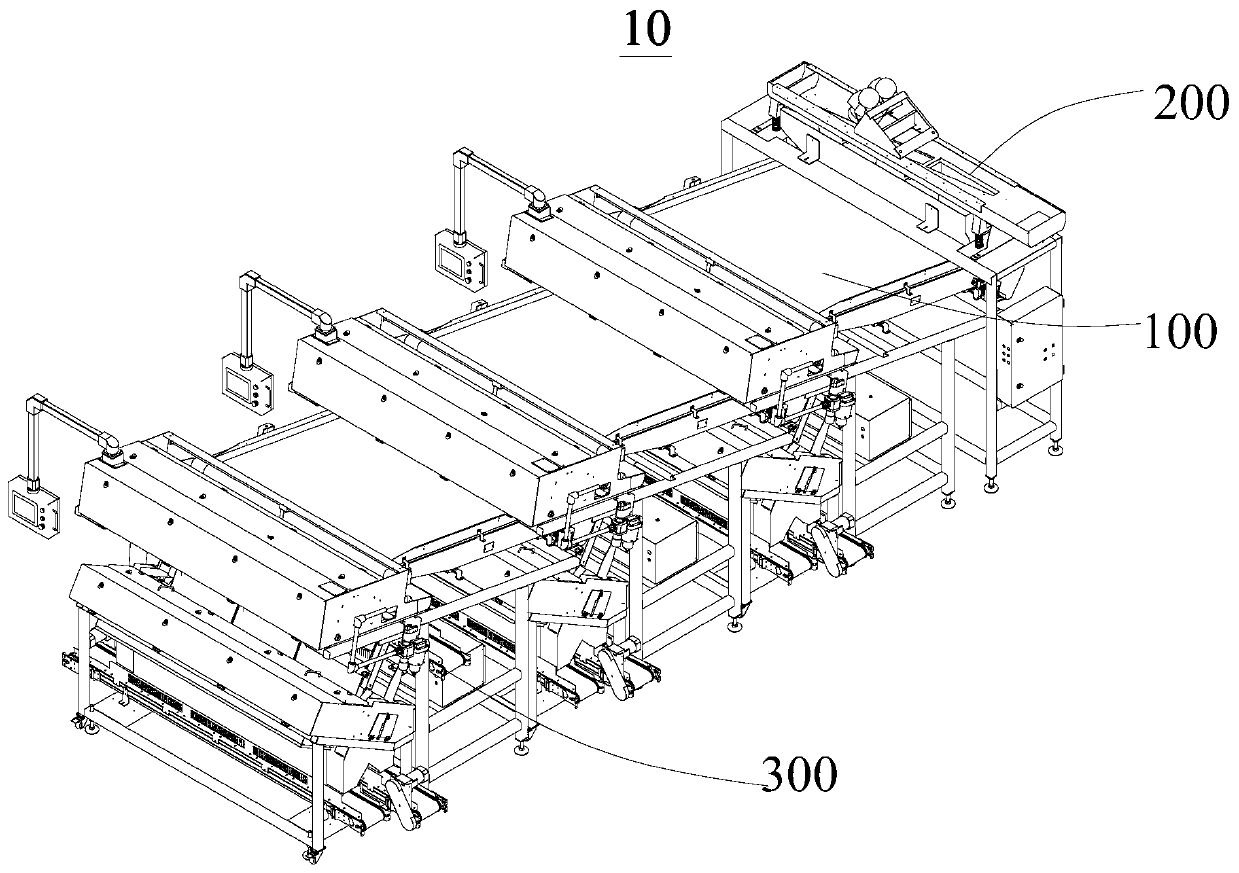

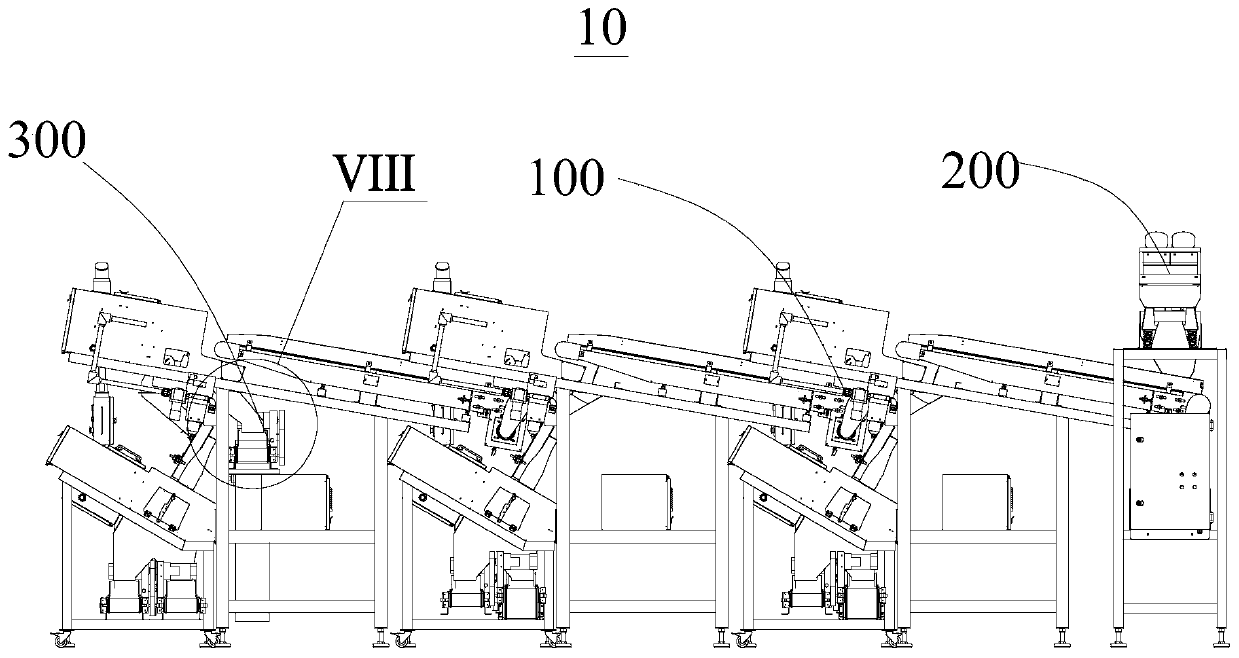

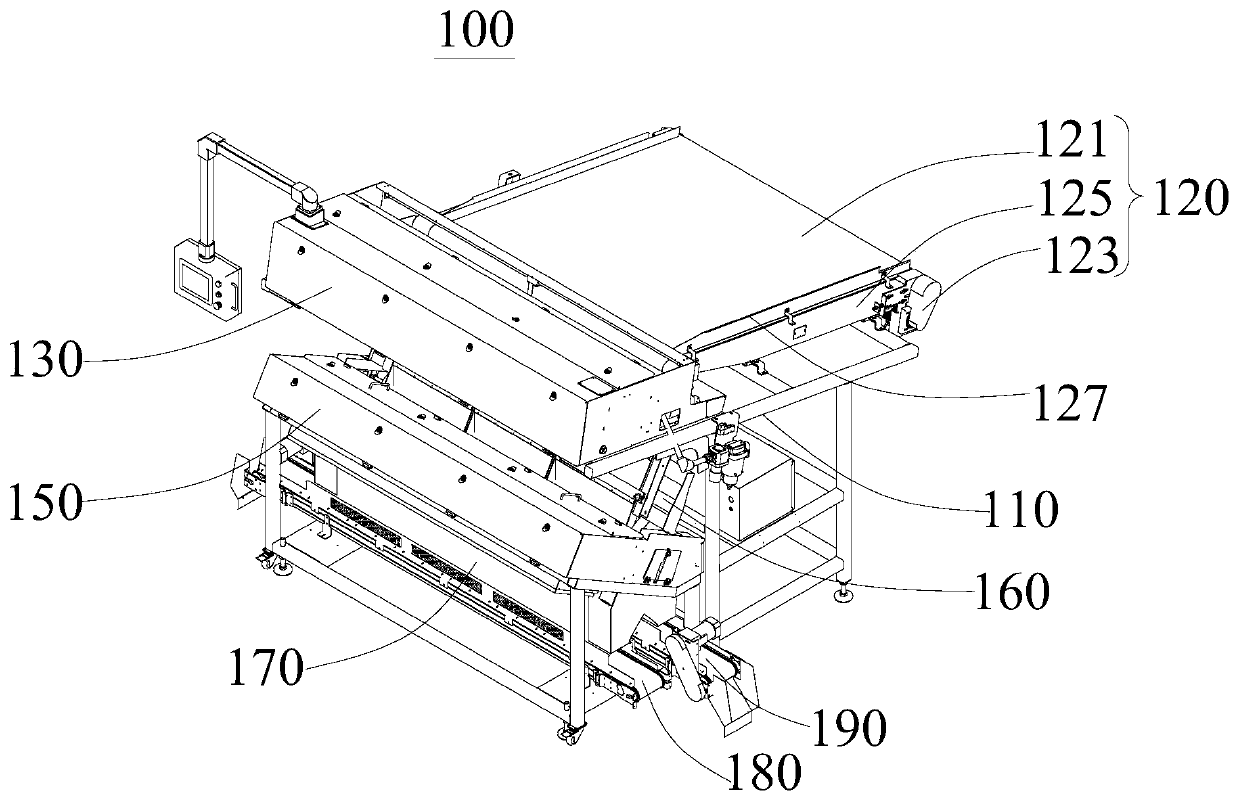

[0040] see in conjunction figure 1 and figure 2 , the present embodiment provides a compound sorting machine 10, comprising a feeding device 200, a discharging device 300 and at least one compound sorting device 100, the feeding device 200 is used for feeding materials, and the compound sorting device 100 is used for sorting material, and in this embodiment, there are multiple composite sorting devices 100, and multiple composite sorting devices 100 are spliced together in series, so that multiple sorting processes can be realized, wherein the feeding device 200 is arranged at the first composite sorting The feeding end of the sorting device 100, the discharging device 300 is connected with the last compound sorting device 100, and is used to send out the qualified materials after sorting.

[0041] It should be noted that the composite sorter 10 mentioned in this embodiment is a color sorter, which separates materials through photoelectric technology and the color of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com