Injection molding device for plastic bend tube

A technology of pipe bending and plastic, applied in the field of plastic pipe bending injection molding device, can solve the problems of product appearance quality not meeting the design requirements, no core pulling device, core pulling deviation, etc., to meet the appearance requirements, prevent dimensional deviation, and easily effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the present invention more obvious and understandable, the detailed description is as follows in conjunction with the accompanying drawings.

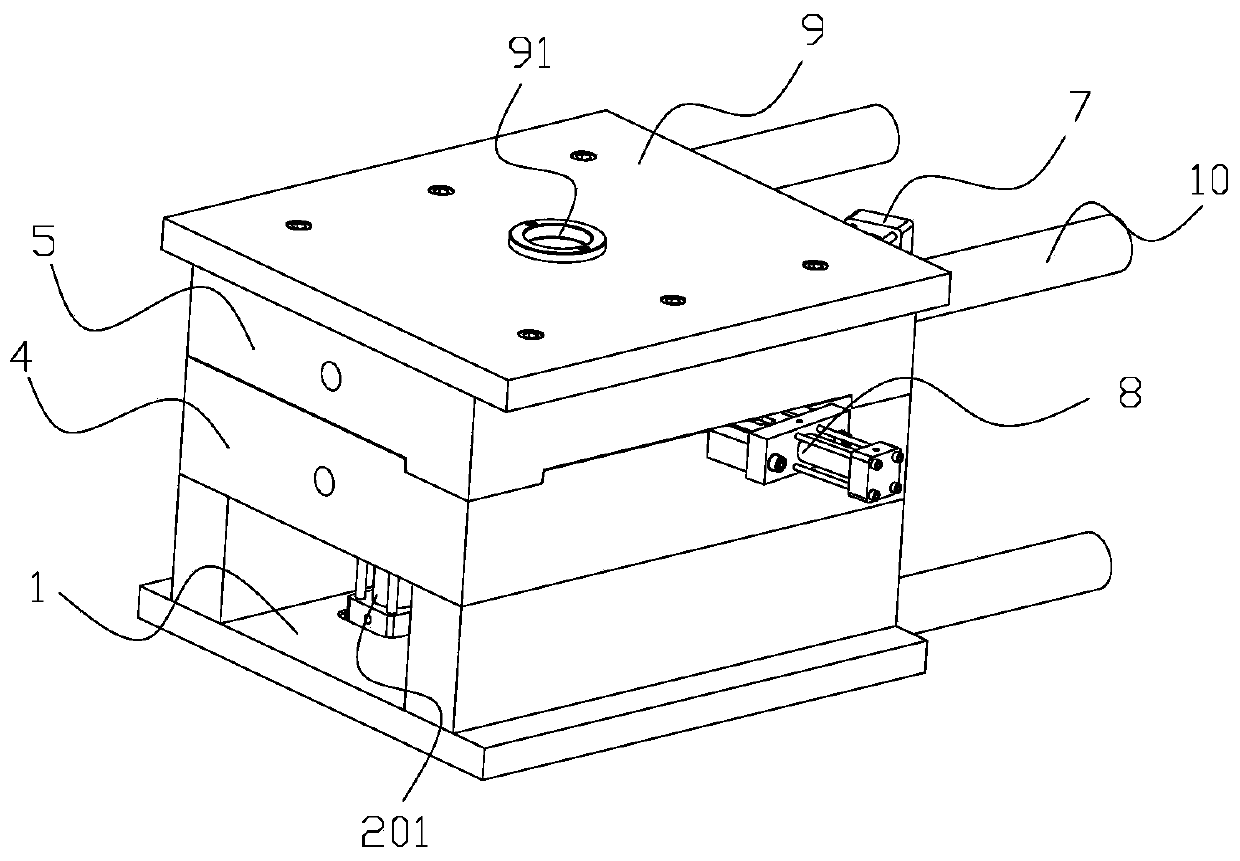

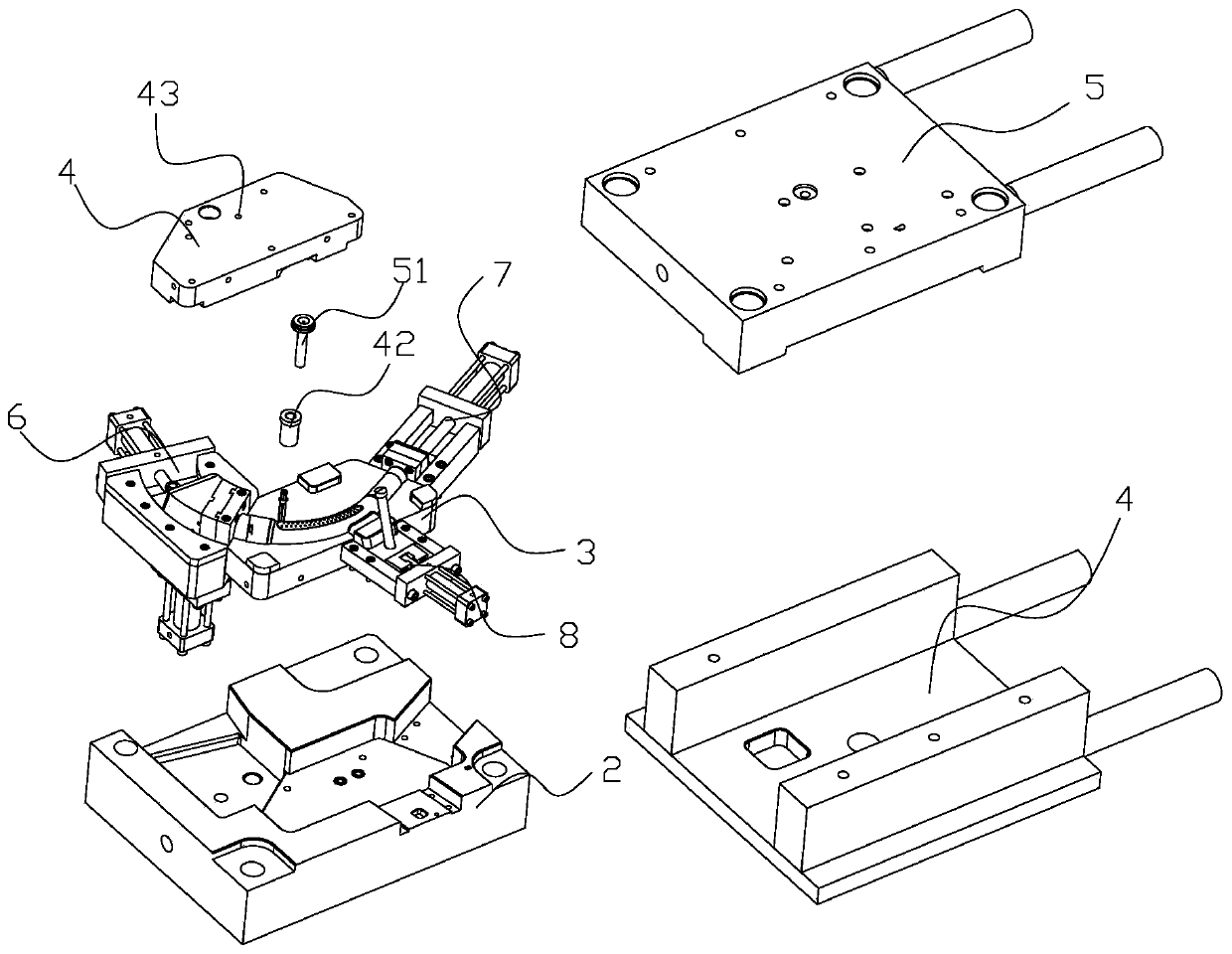

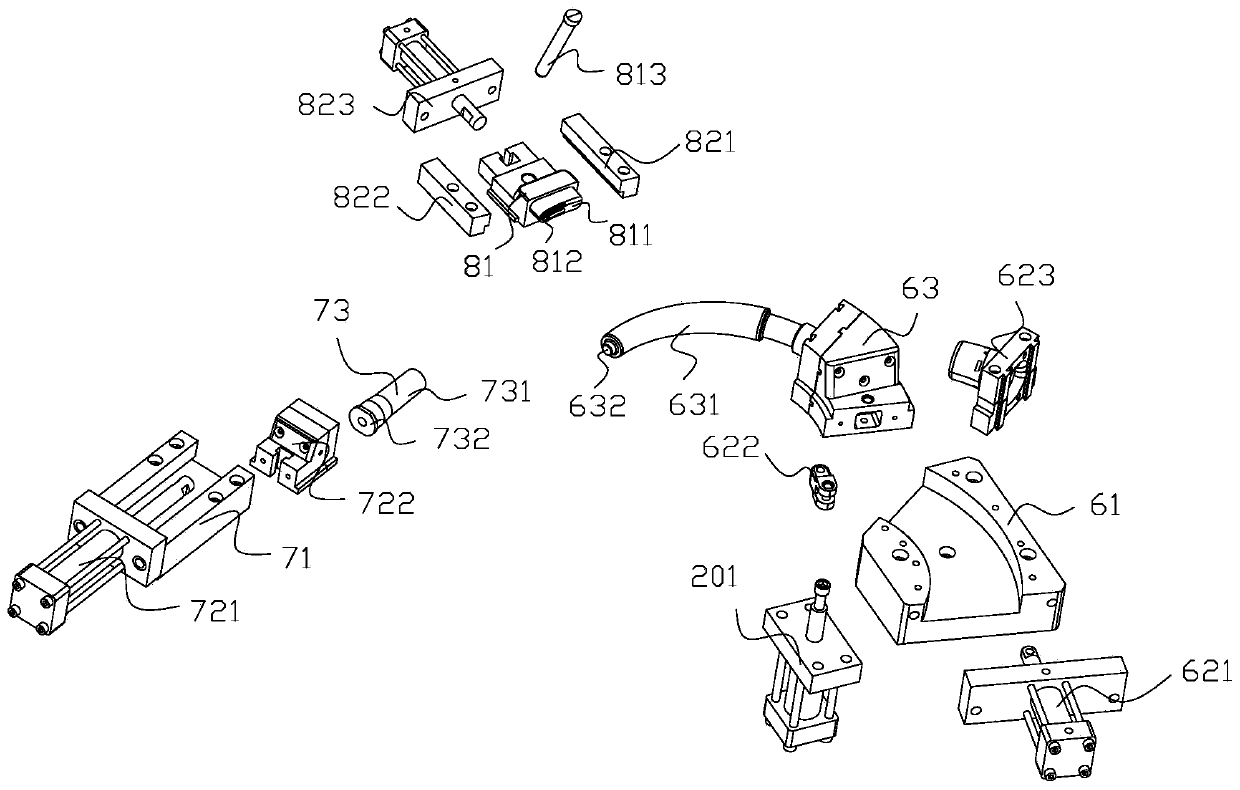

[0025] Such as Figure 1 to Figure 4As shown, a plastic elbow injection molding device includes a base 1, a lower mold base 2, a lower mold 3, an upper mold 4, an upper mold cover 5, a first moving mechanism 6, a second moving mechanism 7 and a third moving mechanism Institution8. The lower mold base 2 is arranged on the base 1 . The lower mold base 2 is provided with a first moving groove 21 , a second moving groove 22 , a third moving groove 23 and a mold groove 24 . The first moving groove 21 is arranged on the left upper part of the lower mold base 2 . The second moving groove 22 is arranged on the right part of the lower mold base 2 . The third moving groove 23 is arranged on the front portion of the lower mold base 2 . The mold groove 24 is arranged in the middle part of the lower mold base 2 . The lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com