Transmission device for hub machining

A technology of transmission device and wheel hub, which is applied in the field of transmission device for wheel hub processing, can solve problems affecting processing efficiency, etc., and achieve the effects of improving processing efficiency, convenient removal process, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

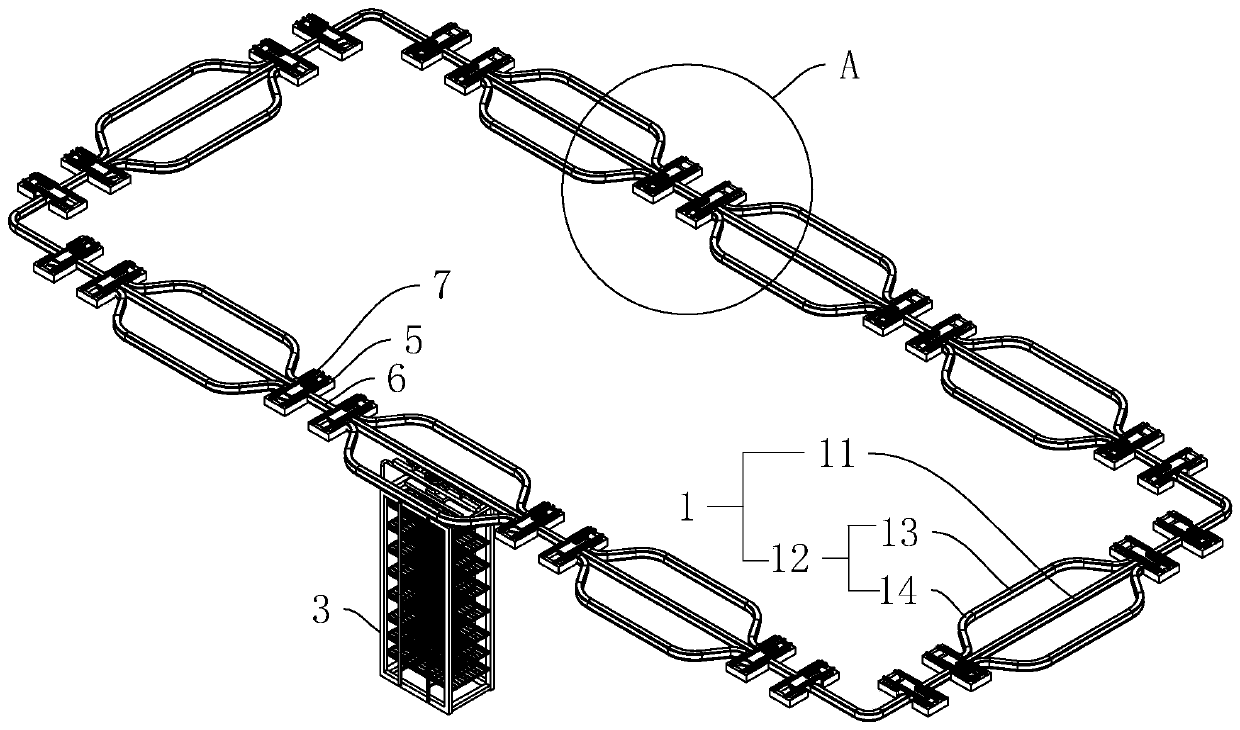

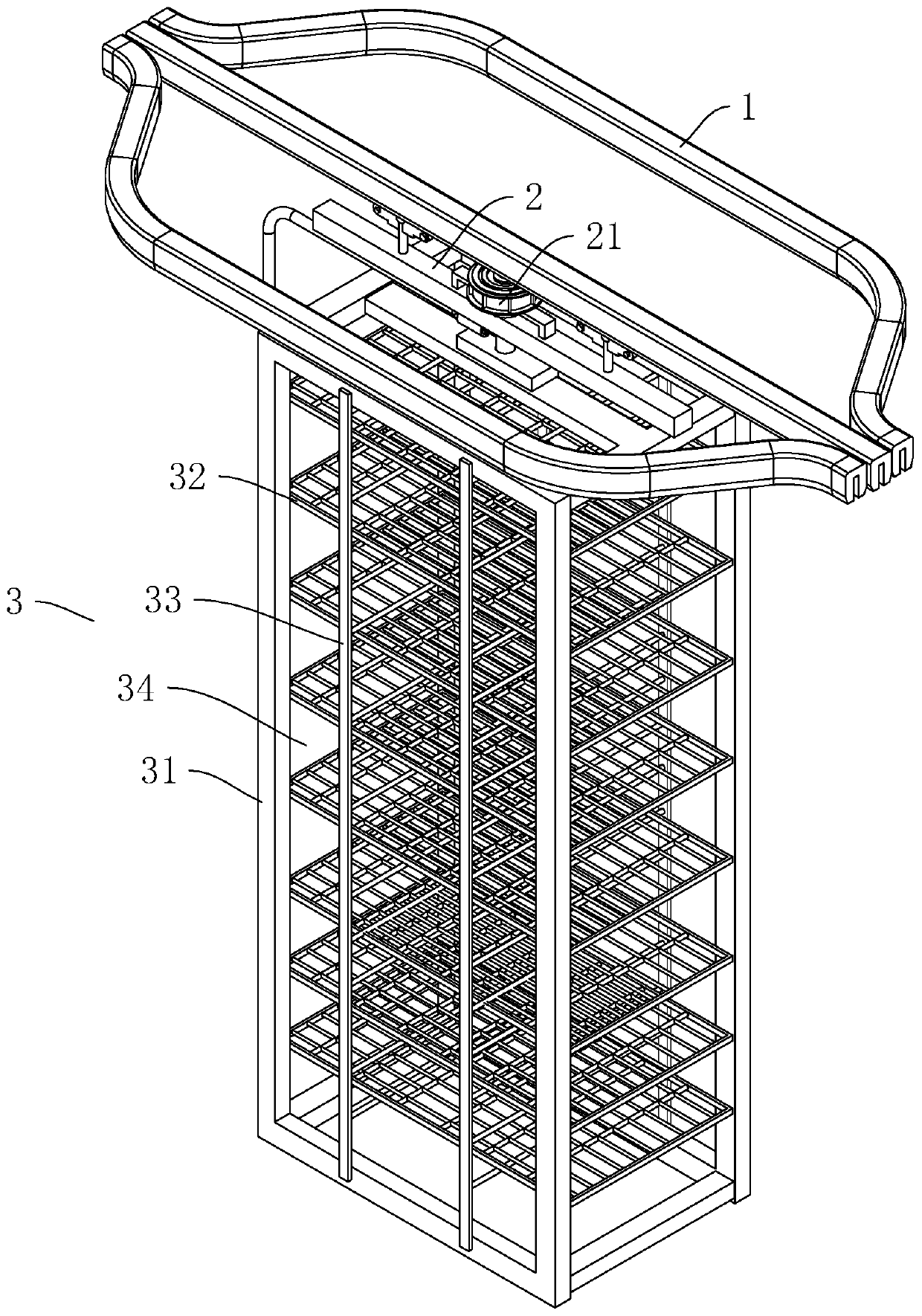

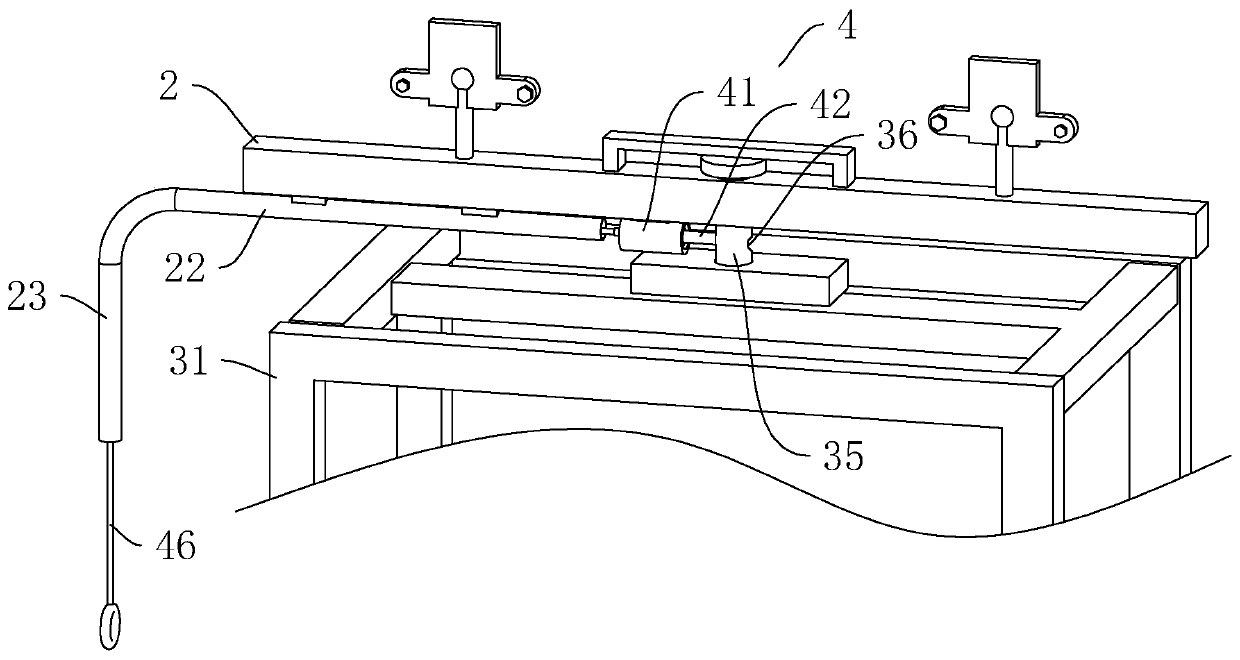

[0038] Such as figure 1 , figure 2 As shown, a transmission device for wheel hub processing includes multiple sets of transmission rails 1 arranged in sequence, and several sliding frames 2 are slidably connected to the transmission rails 1, and a carrier 3 is suspended below the sliding frame 2, and the sliding frame 2 A travel motor 21 for driving the carriage 2 to move is provided on it.

[0039] When the above-mentioned transmission device is used, the blank is placed on the carrier 3, and then the traveling motor 21 is used to drive the sliding frame 2 to slide along the transmission rail 1, and the sliding frame 2 drives the carrier 3 and the blank to move synchronously. When the object carrier 3 moves to the processing equipment position, the traveling motor 21 stops working, and now the blank on the object carrier 3 can be taken off, and the blank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com