Addition-curable silicone composition, cured product, optical element

An addition curing type, silicone technology, applied in the direction of optical components, optics, instruments, etc., can solve the problems of insufficient heat discoloration resistance and large discoloration, and achieve excellent heat discoloration resistance, high refractive index, and high resistance to discoloration. The effect of vulcanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3、 comparative example 1~3

[0133] The following components were mixed at the blending ratio shown in Table 1 to prepare an addition-curable silicone composition. In addition, in Table 1, a part shows a mass part.

[0134] (A-1) Ingredients:

[0135] (CH 2 =CH(CH 3 )(C 6 h 5 ) SiO 1 / 2 ) 2 ((C 6 h 5 ) 2 SiO) 3.8 (SiO 2 ) 4.3 branched chain silicone resin

[0136] (A-2) Ingredients:

[0137] (A-2-a)(CH 2 =CH(CH 3 )(C 6 h 5 ) SiO 1 / 2 ) 2 ((C 6 h 5 ) 2 SiO) 3 Expressed linear silicone oil with a viscosity of 2,000mPa·s

[0138] (A-2-b)(CH 2 =CH(CH 3 )(C 6 h 5 ) SiO 1 / 2 ) 2 ((C 6 h 5 ) 2 Linear silicone oil represented by SiO) with a viscosity of 240mPa·s

[0139] (A-2-c)(CH 2 =CH(CH 3 ) 2 SiO 1 / 2 ) 2 ((C 6 h 5 ) 2 SiO) 3 Expressed linear silicone oil with a viscosity of 700mPa·s

[0140] (B) Ingredients:

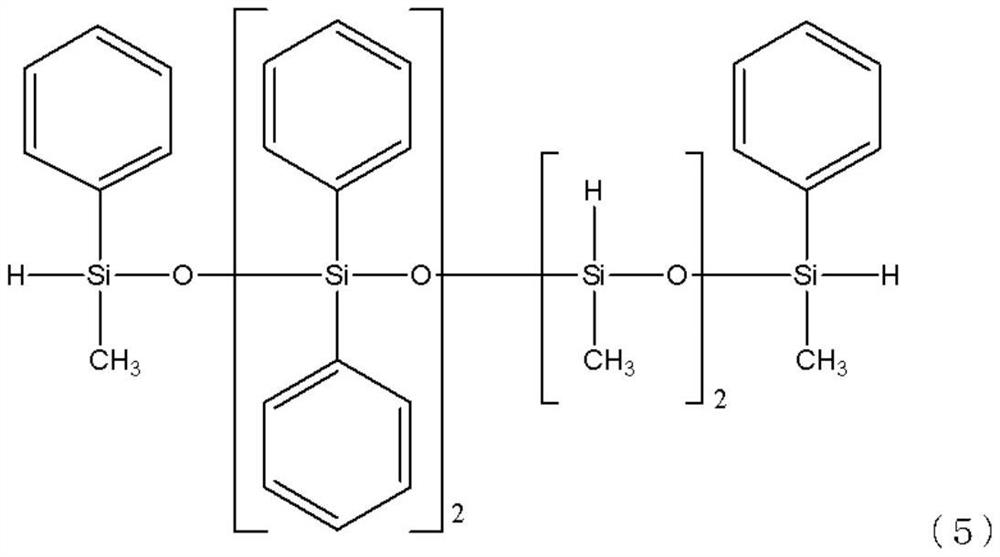

[0141] (B-a) organohydrogenpolysiloxane represented by the following formula (8)

[0142] [chemical formula 14]

[0143]

[0144] In the formula, the arrange...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com