Compound needle for flat knitting machine

A compound needle and flat knitting technology applied to compound needles. It can solve the problems of high processing accuracy of the main needle and needle cover, complex main needle structure, affecting the knitting effect, etc., and achieve the effect of simple and neat transfer action, improved fabric quality, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

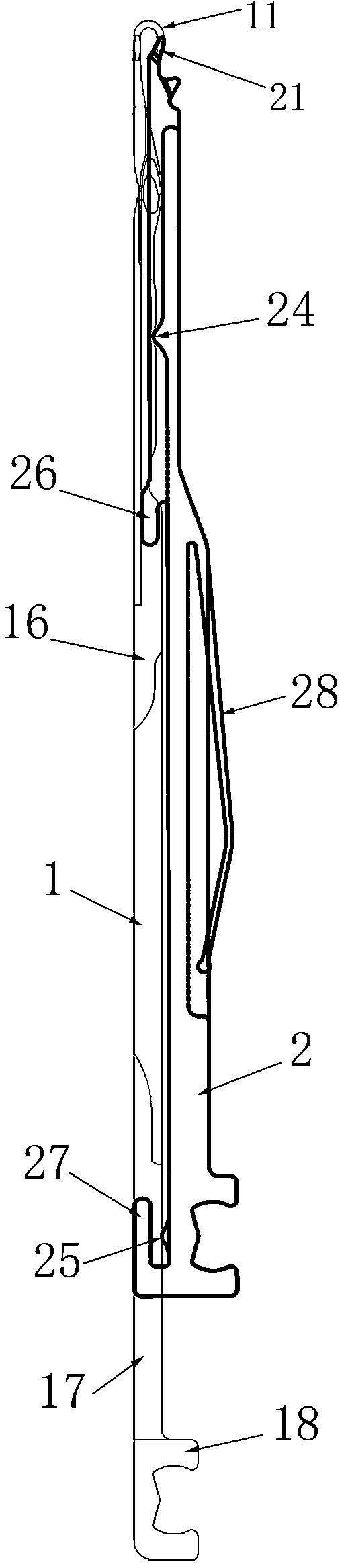

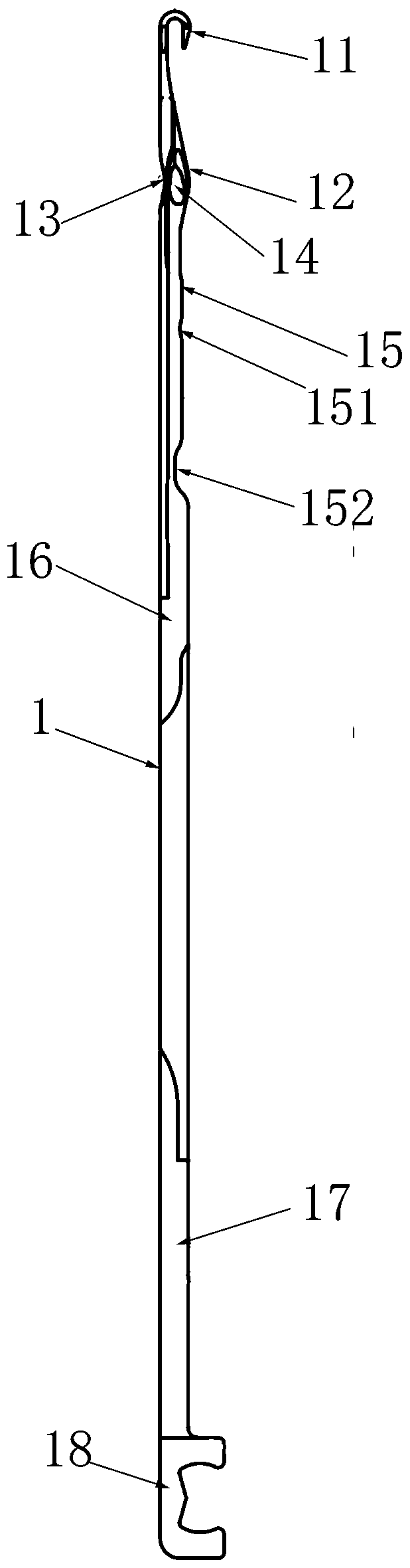

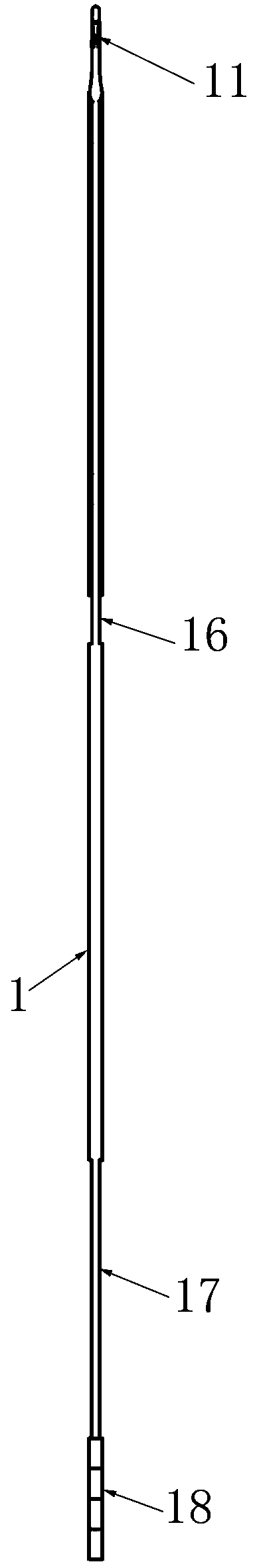

[0038]See attached picture. The compound needle described in this embodiment includes a main needle 1 and a needle sheath 2 fitted on the main needle; the main needle 1 is elongated and has a needle hook 11 on the head, and the bending direction of the needle hook is now defined as On the right side, the opposite direction of the needle hook bending is defined as the left side, and the two planes of the main needle are defined as the front and rear sides; under the needle hook, there is an outwardly protruding boss 12 on the right side of the main needle, opposite to it The left side of the main needle bends inwardly to form a concave avoidance groove 13, so that the size of the coil sliding range on the main needle is kept within a certain range, which is convenient for the movement of the coil on the main needle; the front and rear sides of the boss are provided with There is a recessed accommodating groove 14 for placing the top corner of the needle cover.

[0039] Boss 12...

Embodiment 2

[0048] The compound needle described in this embodiment includes a main needle and a needle cover set on the main needle; a protruding boss is provided on the right side of the main needle, and a concave accommodation groove is provided on the front and rear sides of the boss for use to place the top corner of the socket. There are convex points on the side of the convex platform extending downward, and the side of the needle sleeve facing the main needle is provided with an undulating track surface. The track surface is composed of a plurality of smooth concave-convex surfaces. The upper and lower track surfaces are in contact with each other, and two convex points can be set on the main needle. The two convex points are used to support the sliding of the needle sleeve under pressure, which reduces the contact area, thereby reducing the friction force and facilitating the needle sleeve. Smooth sliding in the needle groove. The track surface of the needle cover is located on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com