Compound needle of flat knitting machine

A compound needle and flat knitting technology, which is applied in the field of knitting machinery, can solve problems such as missing stitches, and achieve the effects of improving production efficiency, reliable use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

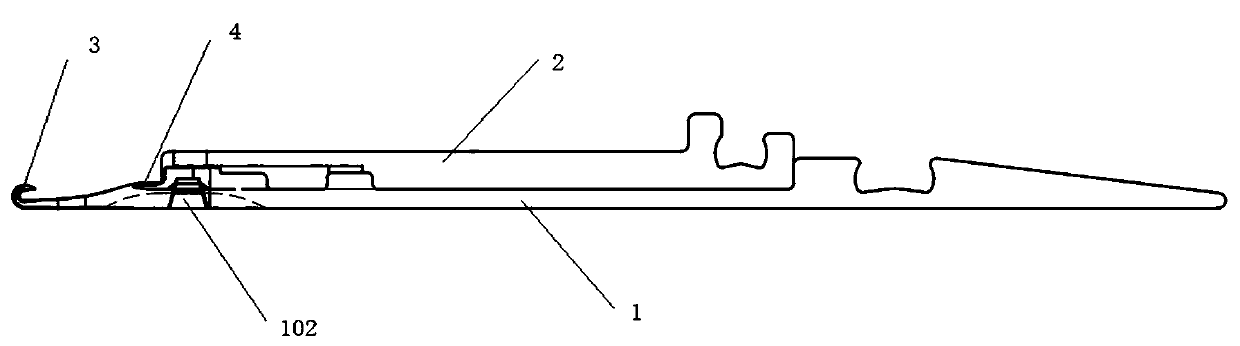

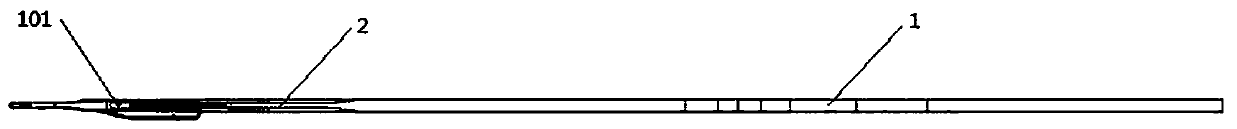

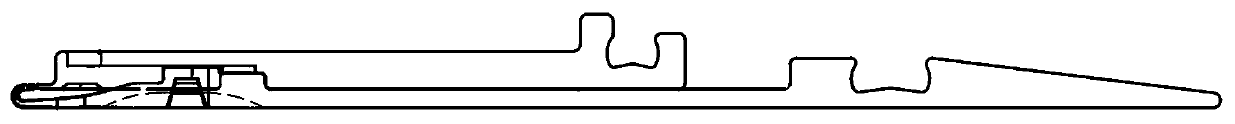

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0029] In the drawings, the thickness, size and shape of objects have been slightly exaggerated for convenience of illustration. The drawings are examples only and are not strictly drawn to scale.

[0030] It should also be understood that the terms "comprising", "having", and "provided with", when used in this specification, indicate the presence of the described features, integers, steps, operations, elements and / or components, but do not exclude the presence of Or additionally have one or more other features, integers, steps, steps, operations, elements, components and / or combinations thereof.

[0031] Such as Figure 1 to Figure 6 As shown, the present invention discloses a compound needle for a flat knitting machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com