A maximum output automatic dredging control method for cutter suction dredger

A cutter suction dredger and control method technology, applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., can solve the problem of high labor intensity, operation level and proficiency affecting dredging Ship construction output and other issues, to achieve the effect of improving quality, improving dredging efficiency, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

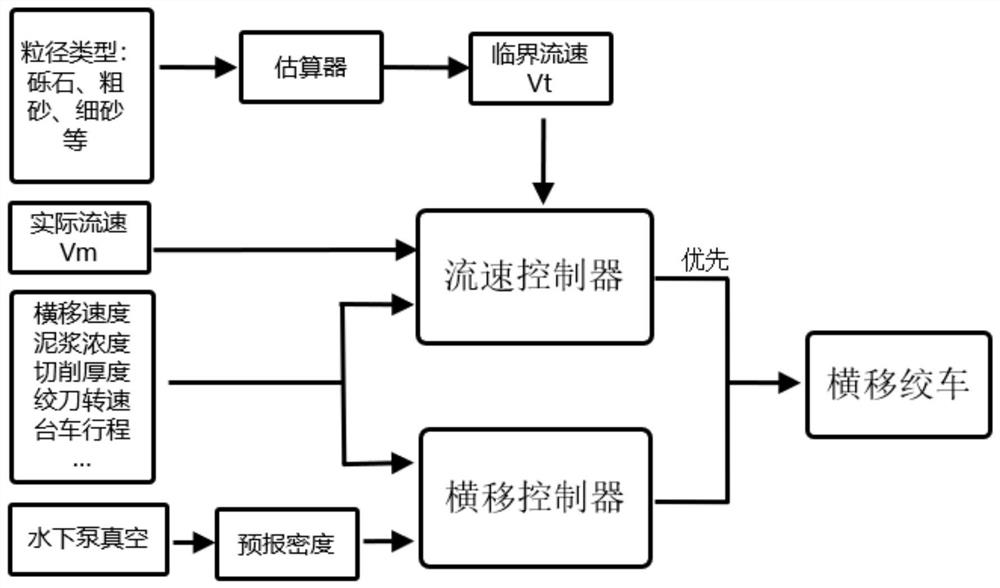

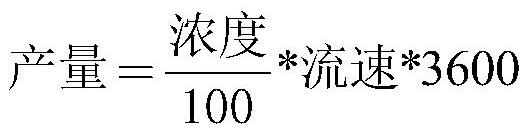

[0021] refer to figure 1 , a maximum output automatic dredging control method of a cutter suction dredger provided in this embodiment, the method is that in any automatic dredging mode, the dredging control system of the cutter suction dredger is calculated by an estimator according to the working conditions The critical flow velocity of pipeline transportation, the calculation formula of critical flow velocity of pipeline transportation is:

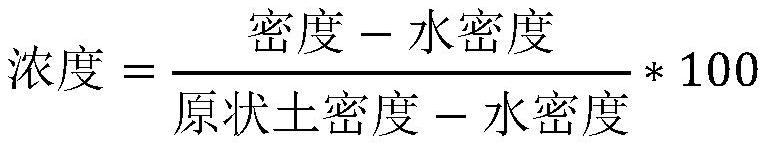

[0022] In the formula, V t Represents the critical flow velocity of pipeline delivery, C vd Represents the average concentration of the pipeline, α is the calculation coefficient obtained according to the experimental data, and the value range is between 5.2-8.7;

[0023] Combined control of cutter suction dredger dredging equipment such as reamer, traversing winch, bridge winch, steel pile trolley and vacuum release valve to realize the dredger's automatic excavation operation according to the construction process, while ensuring th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com