An automatic controller for steel pile trolley of cutter suction dredger

A technology for automatic controllers and cutter suction dredgers, which is applied to earth movers/shovels, mechanically driven excavators/dredgers, construction, etc. and proficiency differences, affecting the smoothness of the connection of dredgers, etc., to achieve the effect of reducing relatively high fuel consumption, reducing fuel consumption, and improving dredging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

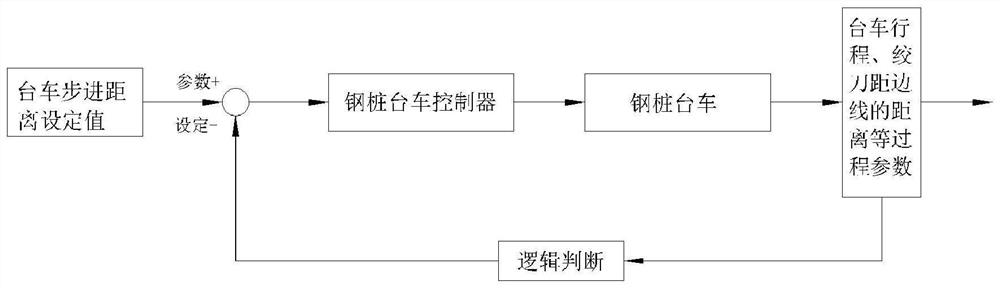

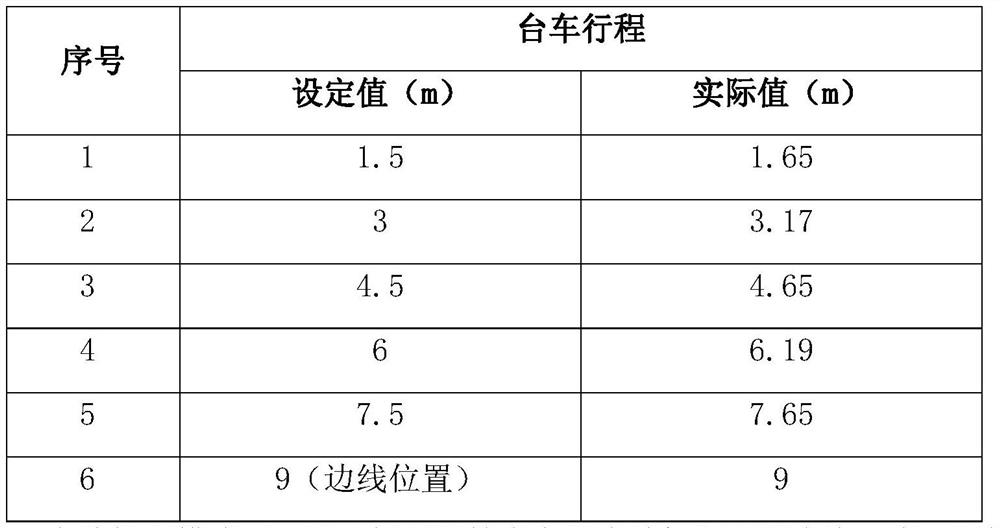

[0020] The automatic controller for the steel pile trolley of the cutter suction dredger of the present invention is to first set the control state and construction parameters in the dredging control system workstation software of the cutter suction dredger under certain working conditions, The dredging control system of the suction dredger and the automatic controller of the steel pile trolley automatically control the steel pile trolley system with one-key entry, one-key exit, sideline automatic entry, or sideline automatic retraction to zero position, so that the dredger can press the construction Process automatic excavation operation, so as to realize efficient automatic dredging.

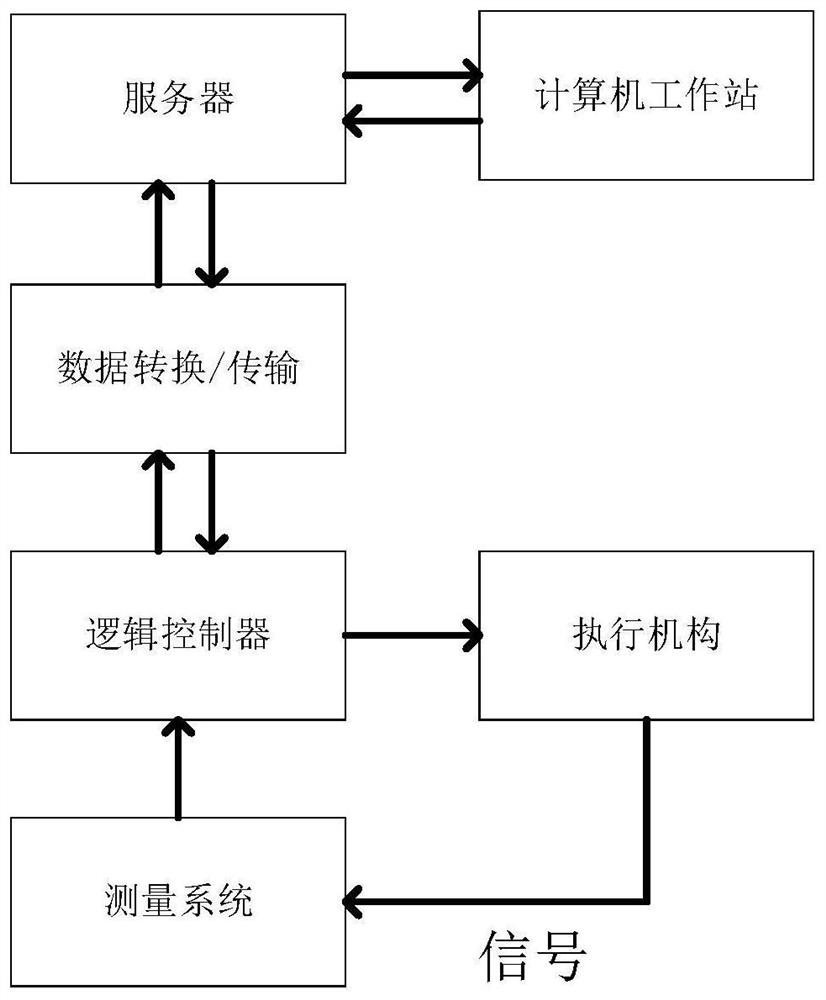

[0021] Such as figure 1 As shown, the dredging control system of the cutter suction dredger based on the automatic controller of the steel pile trolley of the cutter suction dredger of the present invention mainly includes: a measurement system, a logic controller, data conversion / transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com