Construction method for self-compaction of constructional column concrete

A construction method and technology of structural columns, which are applied in building construction, on-site preparation of building components, and processing of building materials. Difficulties and other problems, to achieve the effect of good appearance, high construction efficiency and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

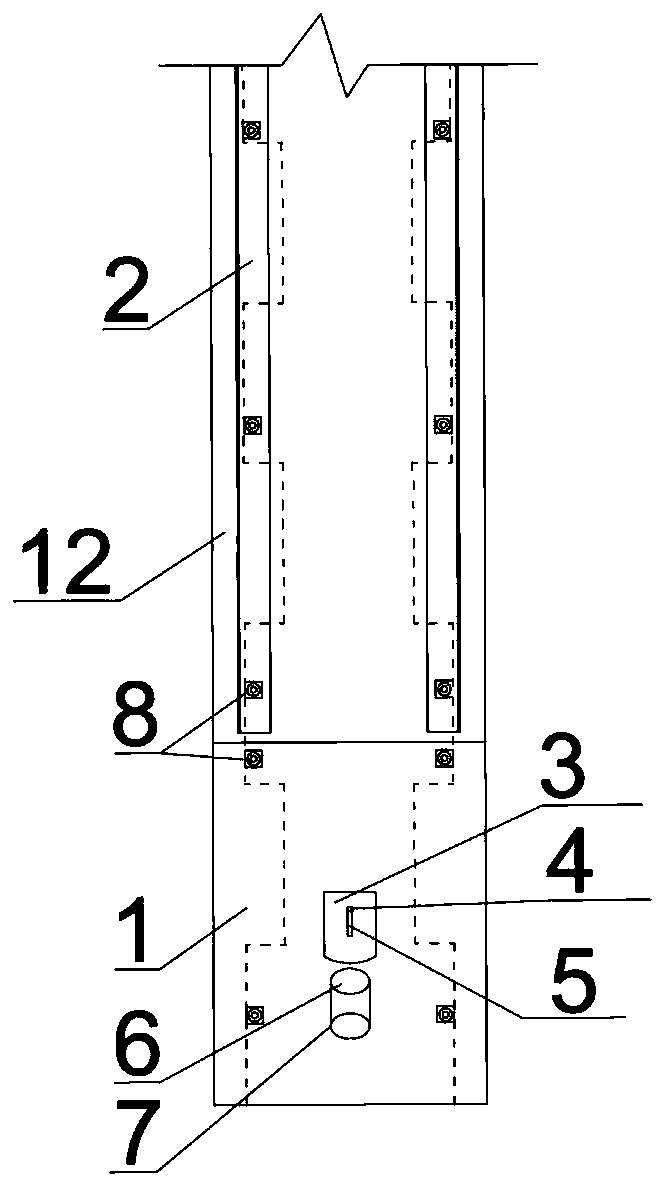

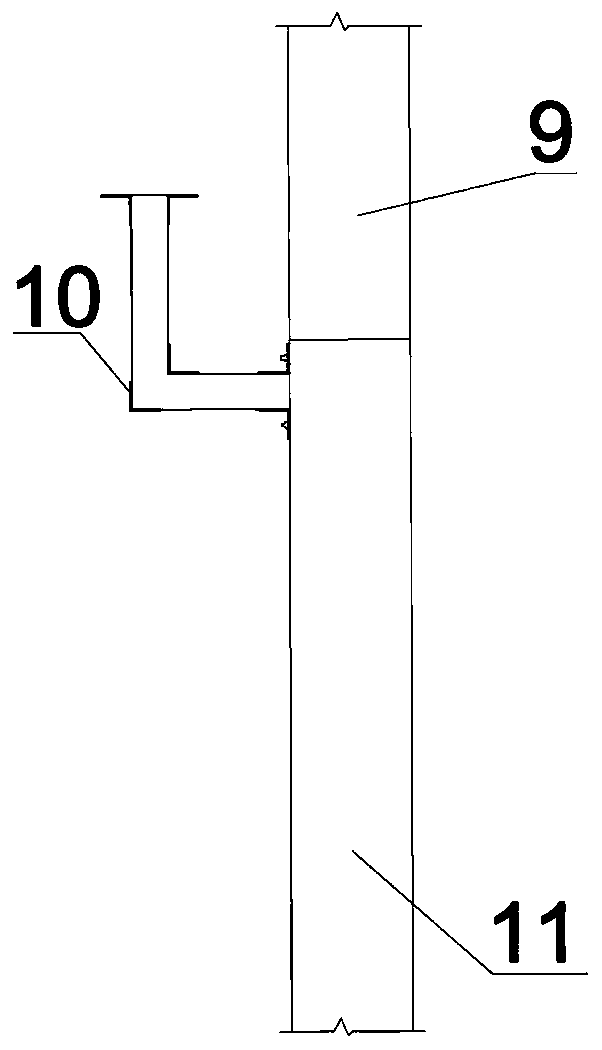

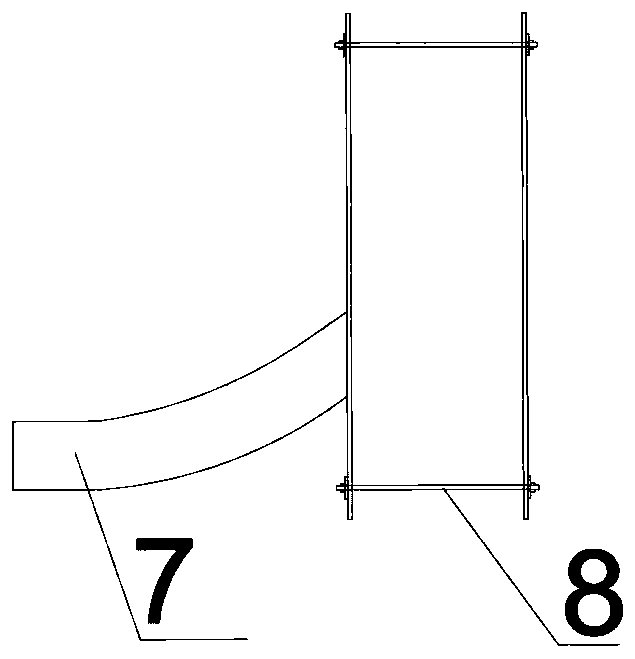

[0029] Embodiment: A kind of construction method of structural column concrete self-compacting, the present invention is applicable to the structural column of various structures, comprises the following steps:

[0030] (1) Concrete mix design: Before preparing self-compacting concrete, carry out trial mixes according to concrete raw materials, transportation distance, concrete pumping performance, delivery pipe diameter, pumping distance and ambient temperature, etc., and strictly implement the "Construction Quality of Concrete Structure Engineering According to relevant provisions of Acceptance Specifications, Technical Regulations for Concrete Pumping Construction, Technical Regulations for Production and Construction of Ready-mixed Concrete, and Technical Regulations for Application of Self-Compacting Concrete, the cement used in the 11th column of the concrete construction column is made of ordinary silicate Cement, sand is medium sand, and the stone gradation must be qual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com