A method for improving the working performance of the main pressure distribution valve used in the governor

A main pressure distribution valve, working performance technology, applied in machine/engine, climate sustainability, sustainable manufacturing/processing, etc., can solve the problem of reducing the working performance of the governor, easy leakage of hydraulic oil, affecting the main pressure distribution valve Work reliability and other issues to achieve the effect of improving good coordination, improving reliability and avoiding wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

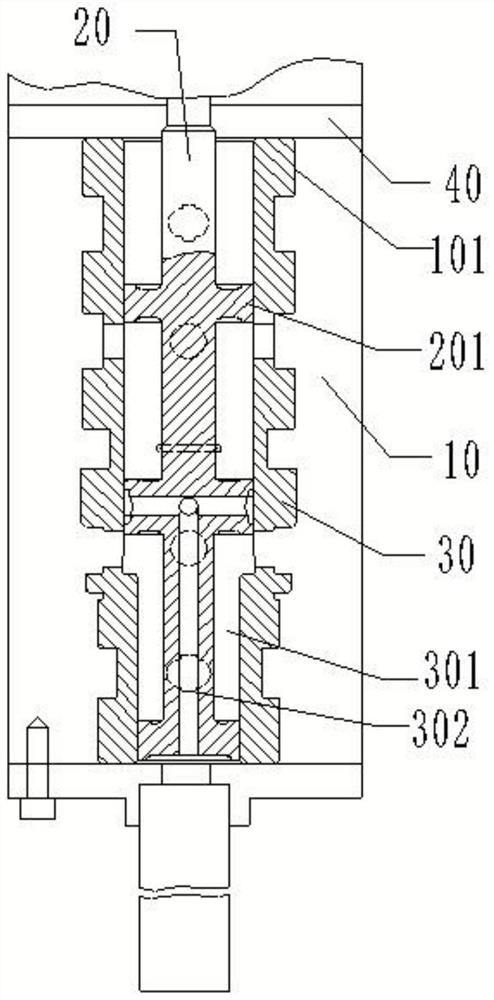

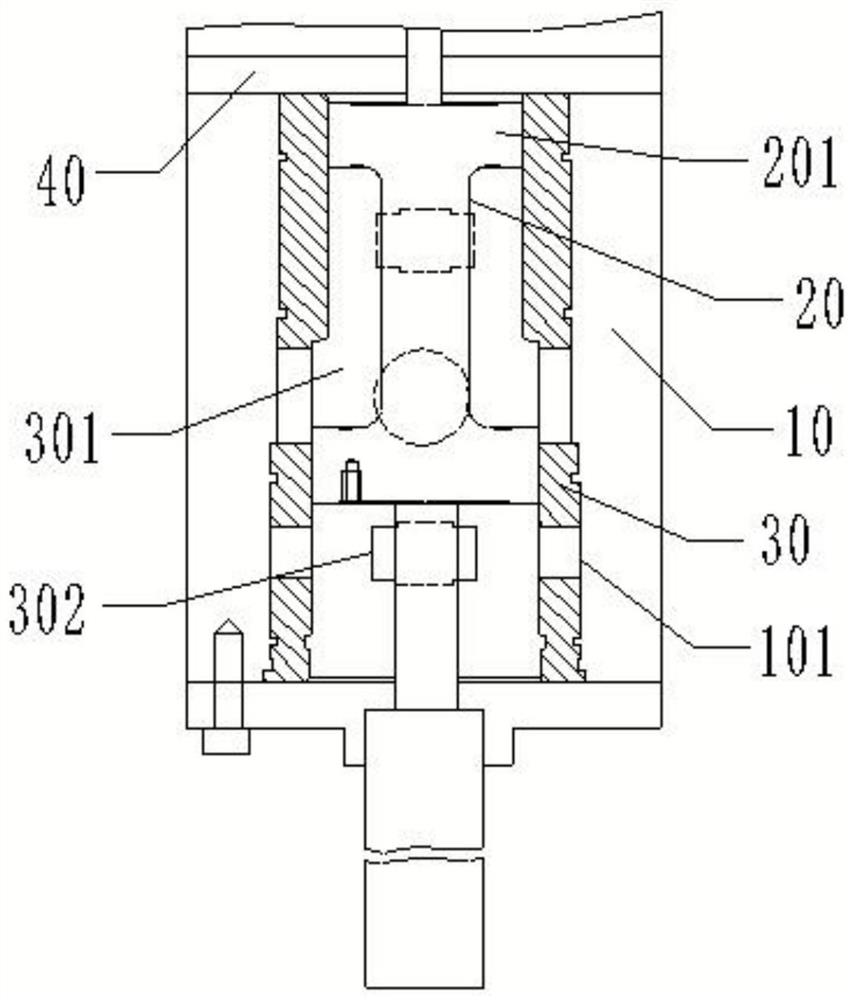

Embodiment 1

[0037] Embodiment 1: Take the main pressure distribution valve formed by the main distribution piston 20 with a valve disc diameter of 28mm and the main distribution bush 30 matched therewith as an example. In order to improve the reliability of the main pressure distribution valve, reduce the oil leakage of the pressure regulating system in the governor, and improve the performance of the main pressure distribution valve for the governor, all the main components of the main pressure distribution valve meet the above requirements, and The surface roughness of the reference plane A of the main piston valve disc 201 and the reference plane A of the main matching bushing’s mounting hole 301 is 0.4 μm, and the coaxiality of the main piston valve disc 201 relative to its reference plane A is φ0.012mm , the coaxiality of the inner diameter of the main matching bush 30 away from the main matching piston 20 relative to its reference plane A is φ0.012mm.

Embodiment 2

[0038]Embodiment 2: Take the main pressure distribution valve formed by the main distribution piston 20 with a valve disc diameter of 80mm and the main distribution bush 30 matched therewith as an example. In order to improve the reliability of the main pressure distribution valve, reduce the oil leakage of the pressure regulating system in the governor, and improve the performance of the main pressure distribution valve for the governor, all the main components of the main pressure distribution valve meet the above requirements, and The surface roughness of the reference plane A of the main piston valve disc 201 and the reference plane A of the main matching bushing’s mounting hole 301 is 0.4 μm, and the coaxiality of the main piston valve disc 201 relative to its reference plane A is φ0.01mm , and the roundness and cylindricity of the main matching piston valve disc 201 are both 0.004mm, the roundness and cylindricity of the installation hole 301 part of the main matching bus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com