Tea-osmanthus composition as well as preparation method and application thereof

A composition and technology of sweet-scented osmanthus, applied in the directions of application and preparation of tobacco, tea flavor, etc., can solve the problems of single taste and poor taste of tea smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

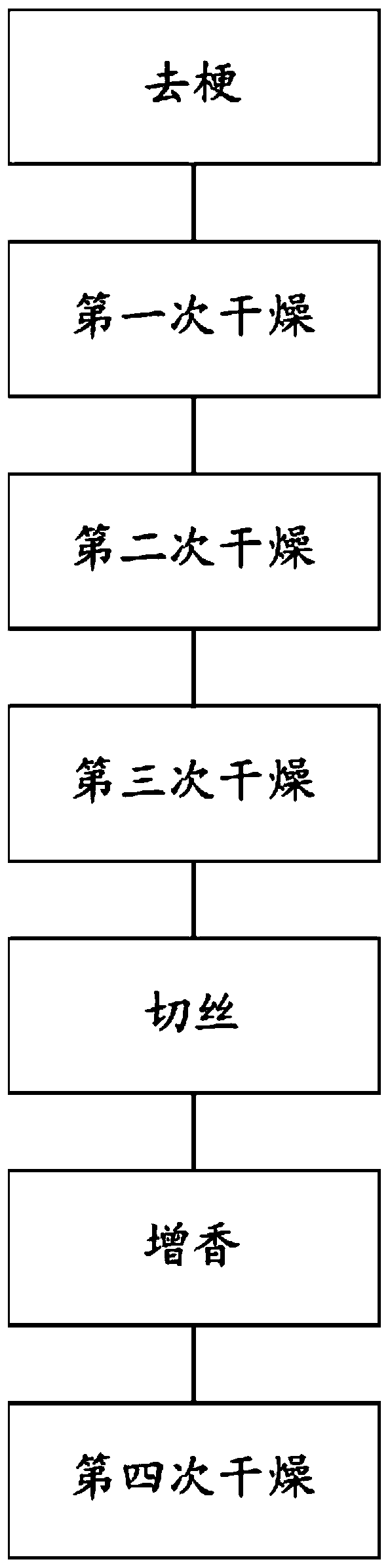

Method used

Image

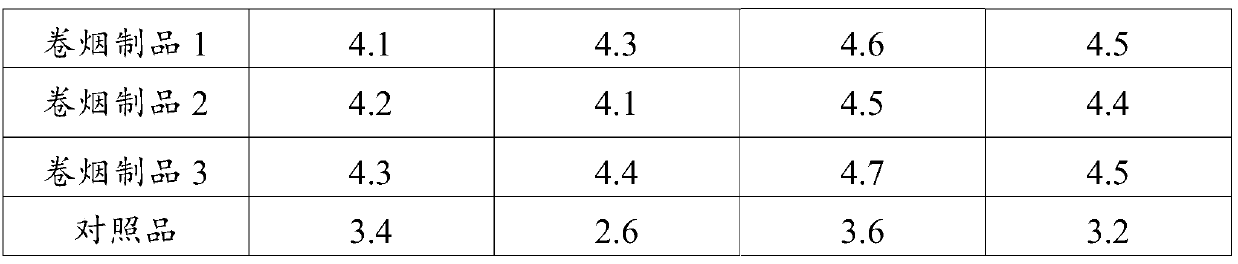

Examples

Embodiment 1

[0033] This embodiment is a specific embodiment for preparing product 1.

[0034] 100Kg of freshly picked oolong tea leaves were removed and dried at 80°C for 60 minutes until the water content decreased by 30%, to obtain the first product 1.

[0035] The first product 1 was dried at 90° C. for 65 minutes until the water content was reduced by 20%, to obtain the second product 1 .

[0036] The second product 1 was dried at 80° C. for 50 min until the water content decreased by 10%, and then allowed to stand at room temperature to obtain the third product 1 .

[0037] The third product 1 mixes with 10Kg sweet-scented osmanthus, cuts into the filament that width is 0.5~2.3mm, sprays tea extract 1 on the surface of gained filament, obtains the 4th product 1; Wherein, the spray amount of tea extract 1 is 4ml / Kg filaments, the preparation method of tea extract 1 is as follows: fresh tea leaves are crushed to 25-35 mesh, dissolved in water, and concentrated at 90°C for 120 minutes ...

Embodiment 2

[0040] This embodiment is a specific embodiment for preparing product 2.

[0041] After destemming 85Kg of freshly picked oolong tea leaves, they were dried at 75°C for 45 minutes until the water content decreased by 30%, and the first product 2 was obtained.

[0042] The first product 2 was dried at 70° C. for 70 minutes until the water content was reduced by 20%, to obtain the second product 2 .

[0043] The second product 2 was dried at 90° C. for 80 min until the moisture content was reduced by 20%, and then allowed to stand at room temperature to obtain the third product 2 .

[0044] The third product 2 mixes with 1Kg sweet-scented osmanthus, cuts into the filament that width is 0.5~2.3mm, sprays tea extract 2 on the surface of gained filament, obtains the 4th product 2; Wherein, the spray amount of tea extract 2 is 5ml / Kg filaments, the preparation method of tea extract 2 is as follows: fresh tea leaves are crushed to 25-35 mesh, dissolved in water, and concentrated at ...

Embodiment 3

[0047] This embodiment is a specific embodiment for preparing product 3.

[0048] The first product 3 was obtained by selecting 80 kg of freshly picked oolong tea leaves and removing the stems, and then drying at 60° C. for 30 minutes until the water content was reduced by 30%.

[0049] The first product 3 was dried at 75° C. for 40 minutes until the water content was reduced by 20%, to obtain the second product 3 .

[0050] The second product 3 was dried at 100° C. for 60 minutes until the water content was reduced by 30%, and then allowed to stand at room temperature to obtain the third product 3 .

[0051] The third product 3 mixes with 20Kg sweet-scented osmanthus, cuts into the filament that width is 0.5~2.3mm, sprays tea extract 3 on the surface of gained filament, obtains the 4th product 3; Wherein, the spray amount of tea extract 3 is 5ml / Kg filaments, the preparation method of tea extract 3 is as follows: fresh tea leaves are crushed to 25-35 mesh, dissolved in water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com