Non-toxic sponge bra

A technology of bras and sponges, applied in the field of bras and underwear, can solve the problems of cancer, poor air permeability of sponges, and toxic fabrics, etc., and achieve the effects of improving skin-friendly properties, softness, support, and support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

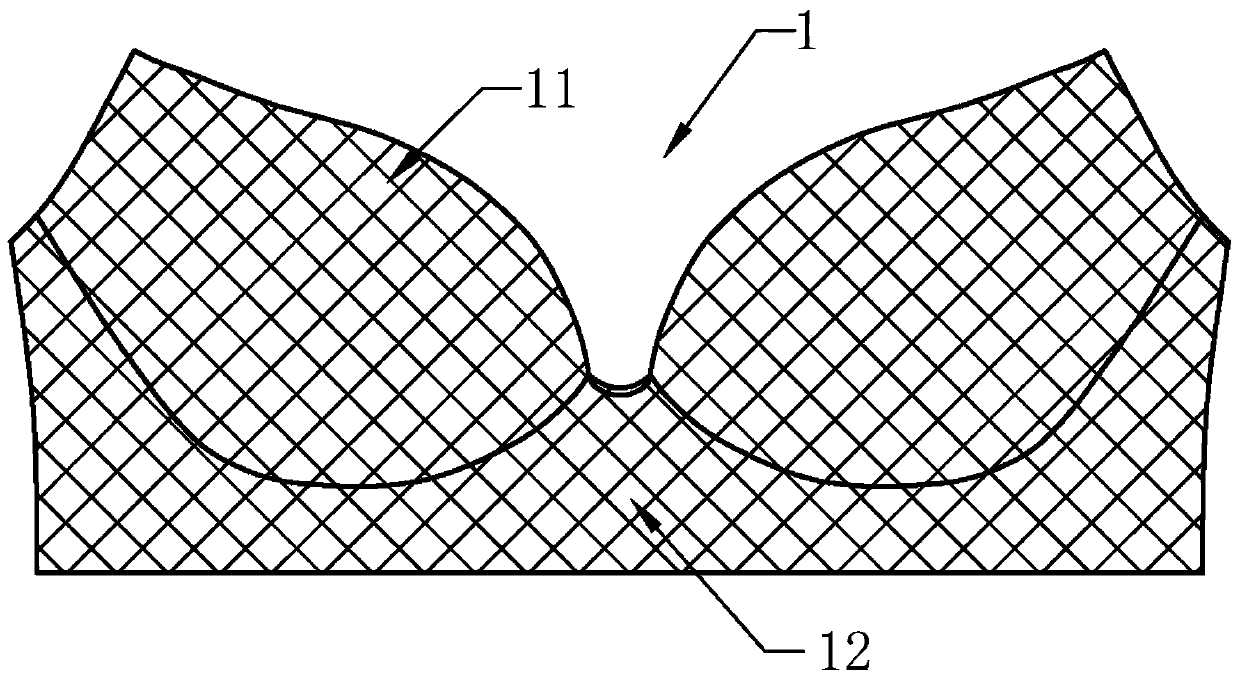

[0066] See figure 1 , 4 , a non-toxic sponge bra, comprising a cup portion 1, the cup portion 1 includes two symmetrically arranged cups 11, a bottom bar 12 surrounded by the bottom and sides of the cups 11, each of the cups 11 includes a The first cotton cloth layer 111, the first non-toxic sponge layer 112, the second non-toxic sponge layer 114, the third non-toxic sponge layer 115 and the second cotton cloth layer 113 connected in sequence, the first cotton cloth layer 111 and the second The thickness of the cotton cloth layer 113 is 0.5-1.0 mm.

[0067]The outer surface of the second nontoxic sponge layer 114 is connected to the inner surface of the first cotton layer 111, and the inner surface of the second nontoxic sponge layer 114 is connected to the outer surface of the third nontoxic sponge layer 115, The inner surface of the third non-toxic sponge layer 115 is connected to the outer surface of the second cotton cloth layer 113; the second cotton cloth layer 113 is ...

Embodiment 2

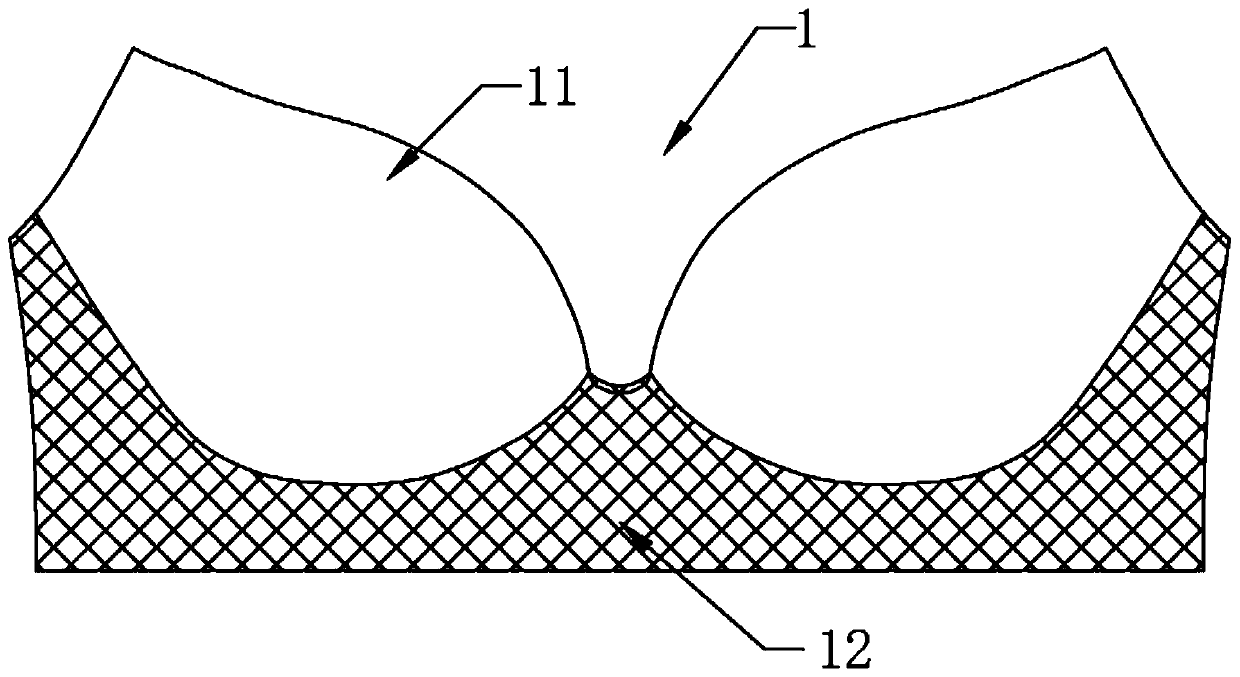

[0076] See figure 2 , 5 , a non-toxic sponge bra, comprising a cup portion 1, the cup portion 1 includes two symmetrically arranged cups 11, a bottom grill 12 surrounded by the bottom and sides of the cups 11, each of the cups 11 includes The first cotton cloth layer 111, the first non-toxic sponge layer 112, the second non-toxic sponge layer 114, the third non-toxic sponge layer 115 and the second cotton cloth layer 113 connected in sequence, the first cotton cloth layer 111 and the second The thickness of the cotton cloth layer 113 is 0.5-1.0 mm.

[0077] The outer surface of the second nontoxic sponge layer 114 is connected to the inner surface of the first cotton layer 111, and the inner surface of the second nontoxic sponge layer 114 is connected to the outer surface of the third nontoxic sponge layer 115, The inner surface of the third non-toxic sponge layer 115 is connected to the outer surface of the second cotton cloth layer 113; the second cotton cloth layer 113 i...

Embodiment 3

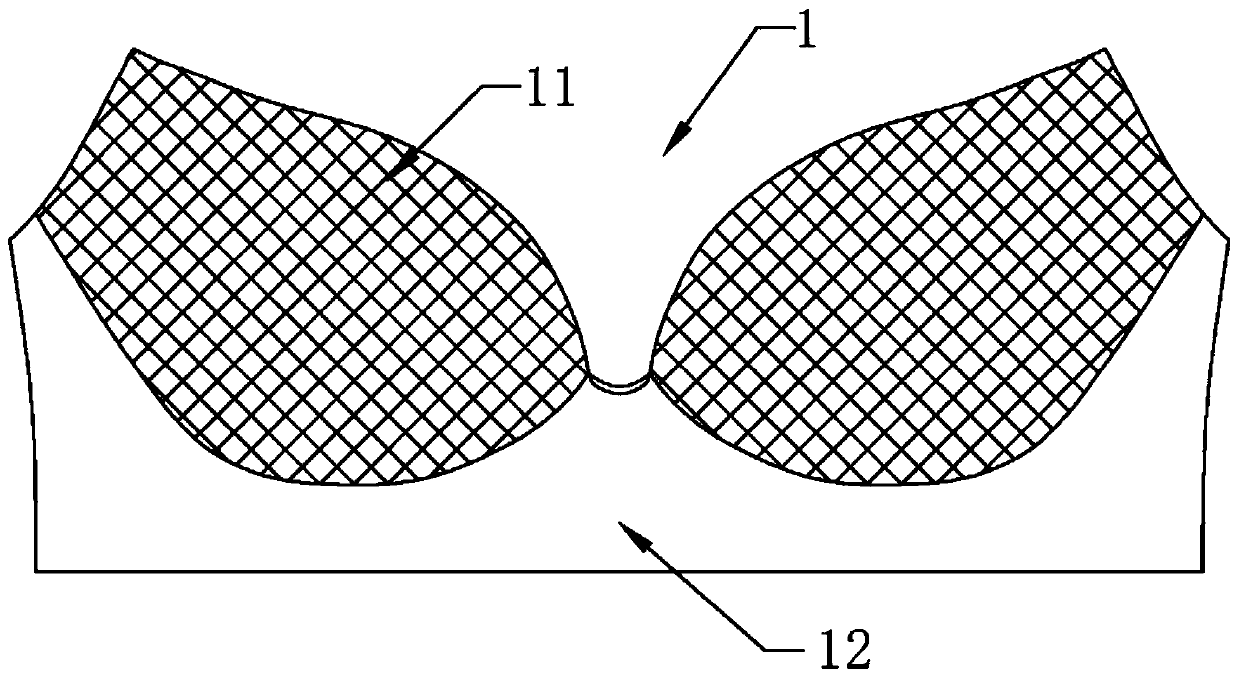

[0086] See image 3 , 6 , a non-toxic sponge bra, comprising a cup portion 1, the cup portion 1 includes two symmetrically arranged cups 11, a bottom grill 12 surrounded by the bottom and sides of the cups 11, each of the cups 11 includes The first cotton cloth layer 111, the first nontoxic sponge layer 112, the fourth nontoxic sponge layer 118 and the second cotton cloth layer 113 connected in sequence, the thickness of the first cotton cloth layer 111 and the second cotton cloth layer 113 are 0.5 -1.0mm.

[0087] The outer surface of the fourth nontoxic sponge layer 118 is connected to the inner surface of the first nontoxic sponge layer 112, and the inner surface of the fourth nontoxic sponge layer is connected to the inner surface of the second cotton cloth layer 113; The second cotton cloth layer 113 is a brushed cotton cloth layer; the thicknesses of the first non-toxic sponge layer 112 and the fourth non-toxic sponge layer 118 are both 4.5mm.

[0088] The cup 11 also...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com