High-pressure spraying cooling casting forming process

A casting molding, high-pressure spraying technology, applied in the field of auto parts casting, can solve the problems of gas can not be completely eliminated, mold exhaust system parts increase, affect product strength and other problems, to facilitate the leakage of aluminum water to the holding furnace, improve the utilization of aluminum liquid rate, and the effect of improving product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with specific examples.

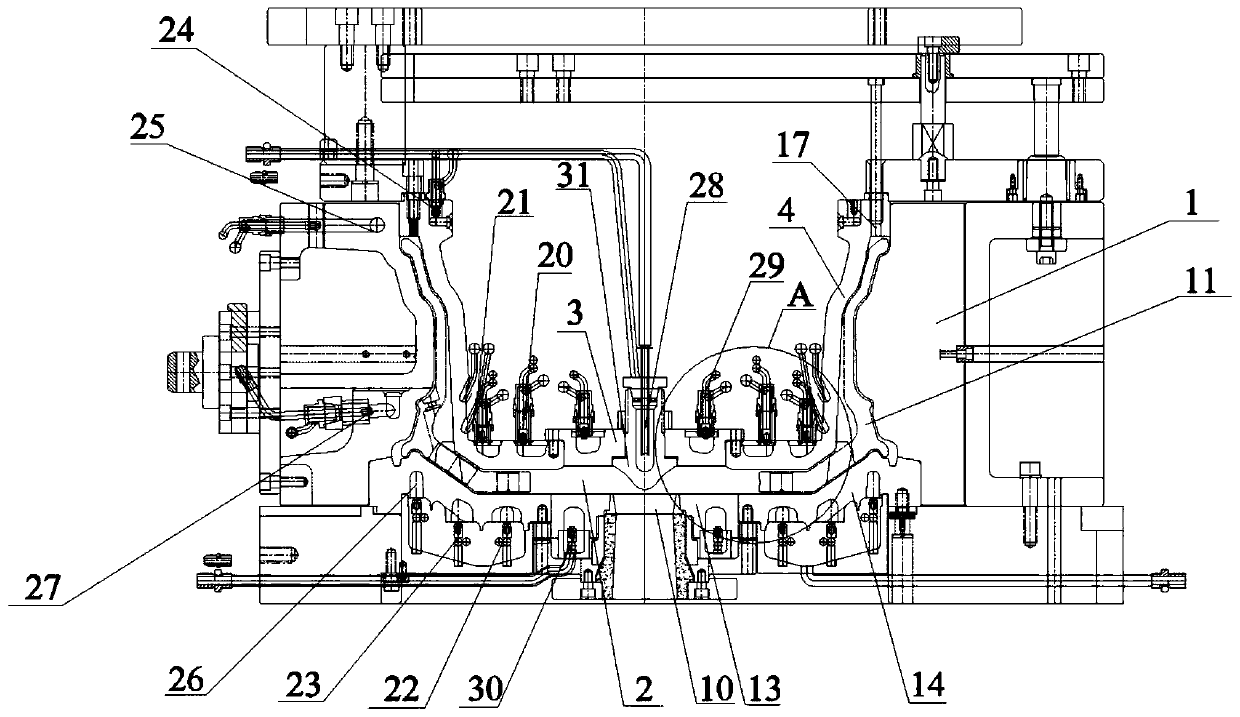

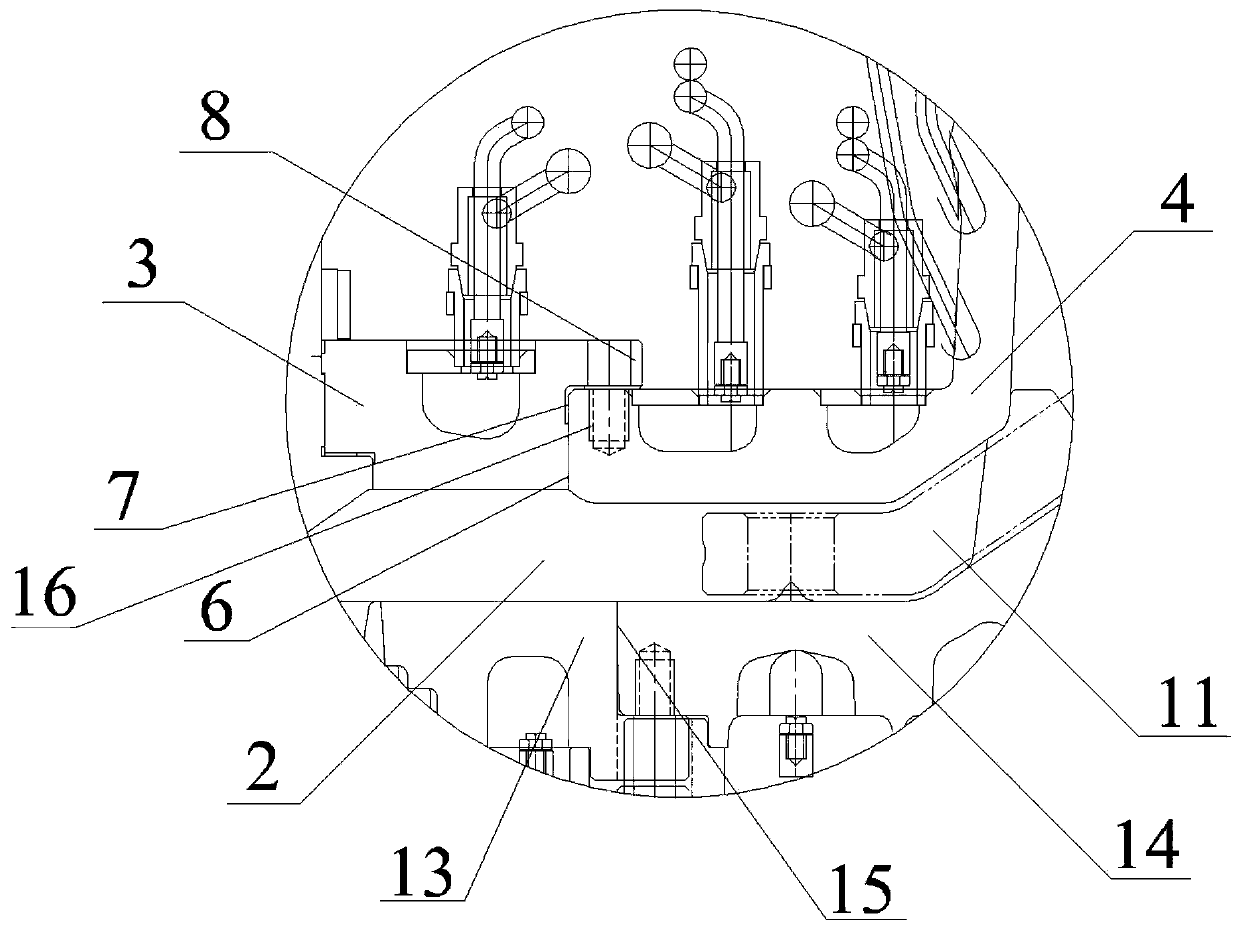

[0048] see Figure 1-10 , The low-pressure casting method disclosed in the present invention is based on the following hub mold, which includes an upper mold, a lower mold and a side mold 1, and the upper mold, lower mold and side mold 1 enclose a hub cavity 2.

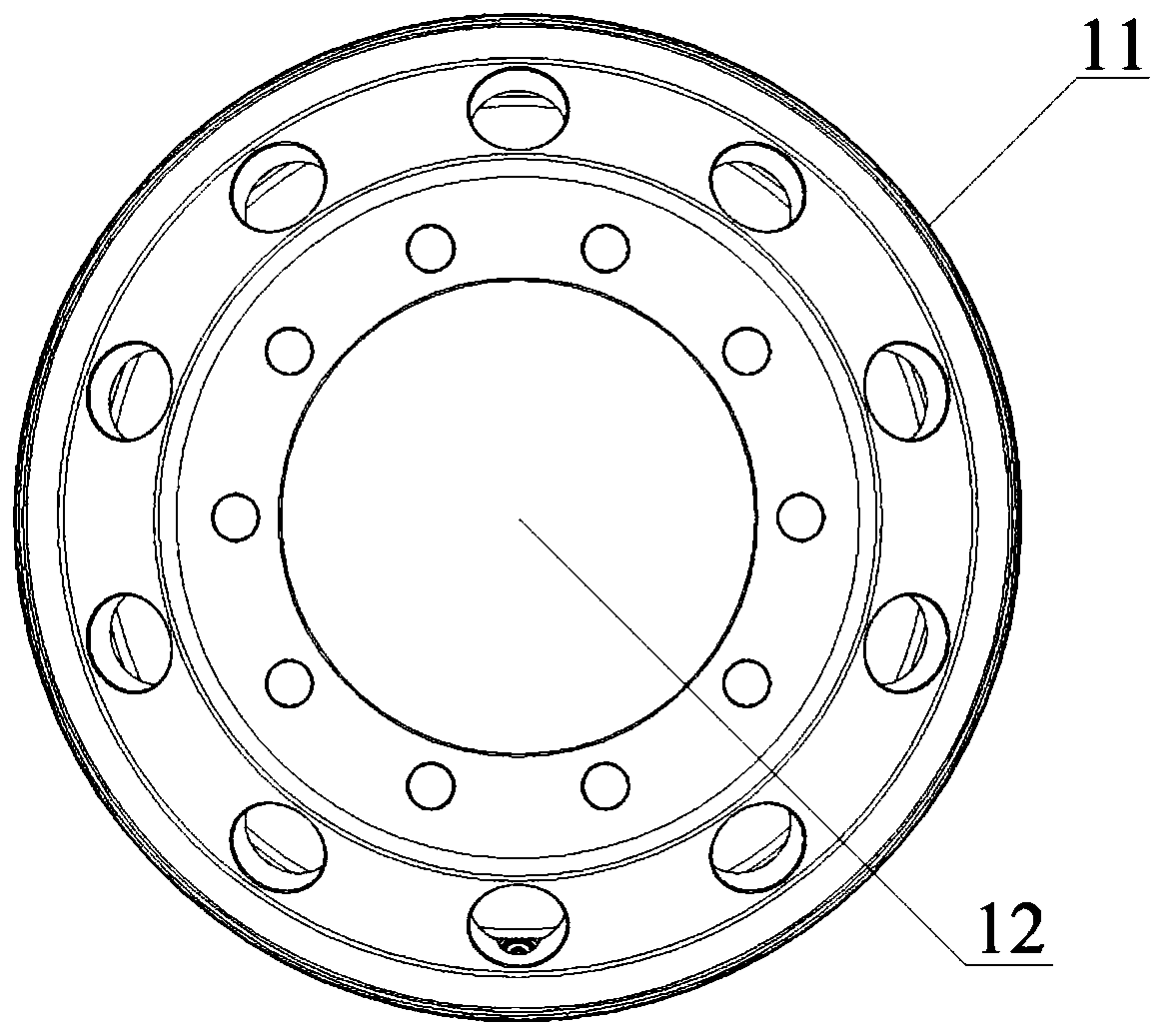

[0049] The sprue 10 on the lower mold communicates with a holding furnace (not shown) filled with molten aluminum. During low-pressure casting, the holding furnace is pressurized so that the aluminum liquid enters the hub cavity 2 under pressure. After a period of heat preservation, the pressure is released to obtain the automobile hub 11. see figure 2 , the central part of the automobile hub 11 is the central hole 12 .

[0050] The upper mold is formed by splicing the upper mold core 3 and the upper template 4, and the lower end surface of the upper template 4 is provided with criss-cross exhaust line groups 5. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com