Positive drive lift

A technology of forced drive and elevator, which is applied to elevators, elevators, transportation and packaging in buildings, etc. It can solve problems such as elevator structure mismatch, achieve compact and reasonable overall structure, simplify component structure, and reduce roof construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

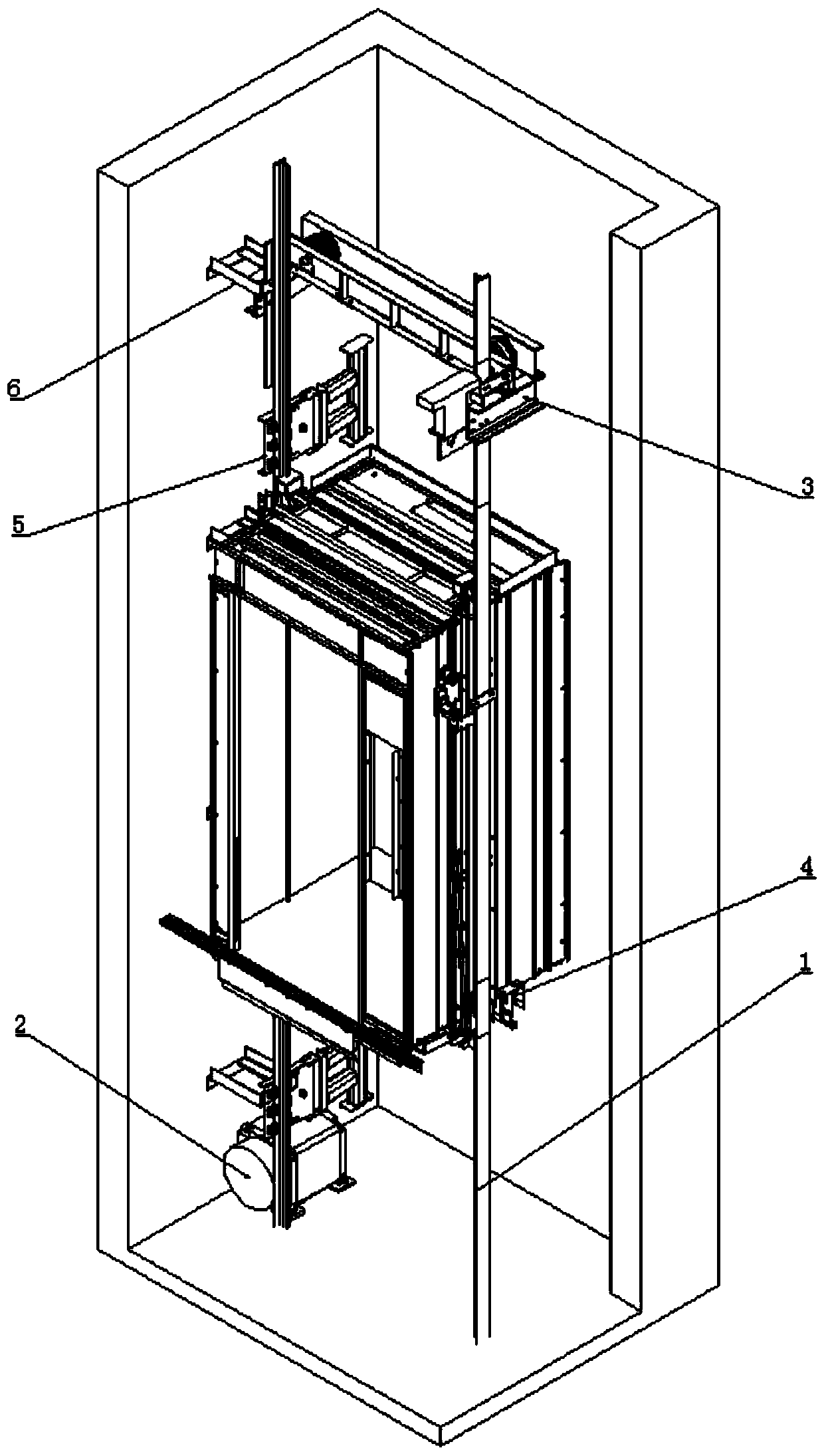

[0038]A forced-drive elevator includes a car guide rail 1, a main engine 2, an anti-sheave device 3, a car floor assembly 4, and a traction rope.

[0039] Wherein, the car guide rail 1 includes two guide rails with a T-shaped cross section, and the two guide rails are arranged symmetrically on both sides of the hoistway;

[0040] The host 2 is fixed at the bottom of the hoistway, and the host 1 is arranged between the car guide rail 1 on one side and the wall of the hoistway.

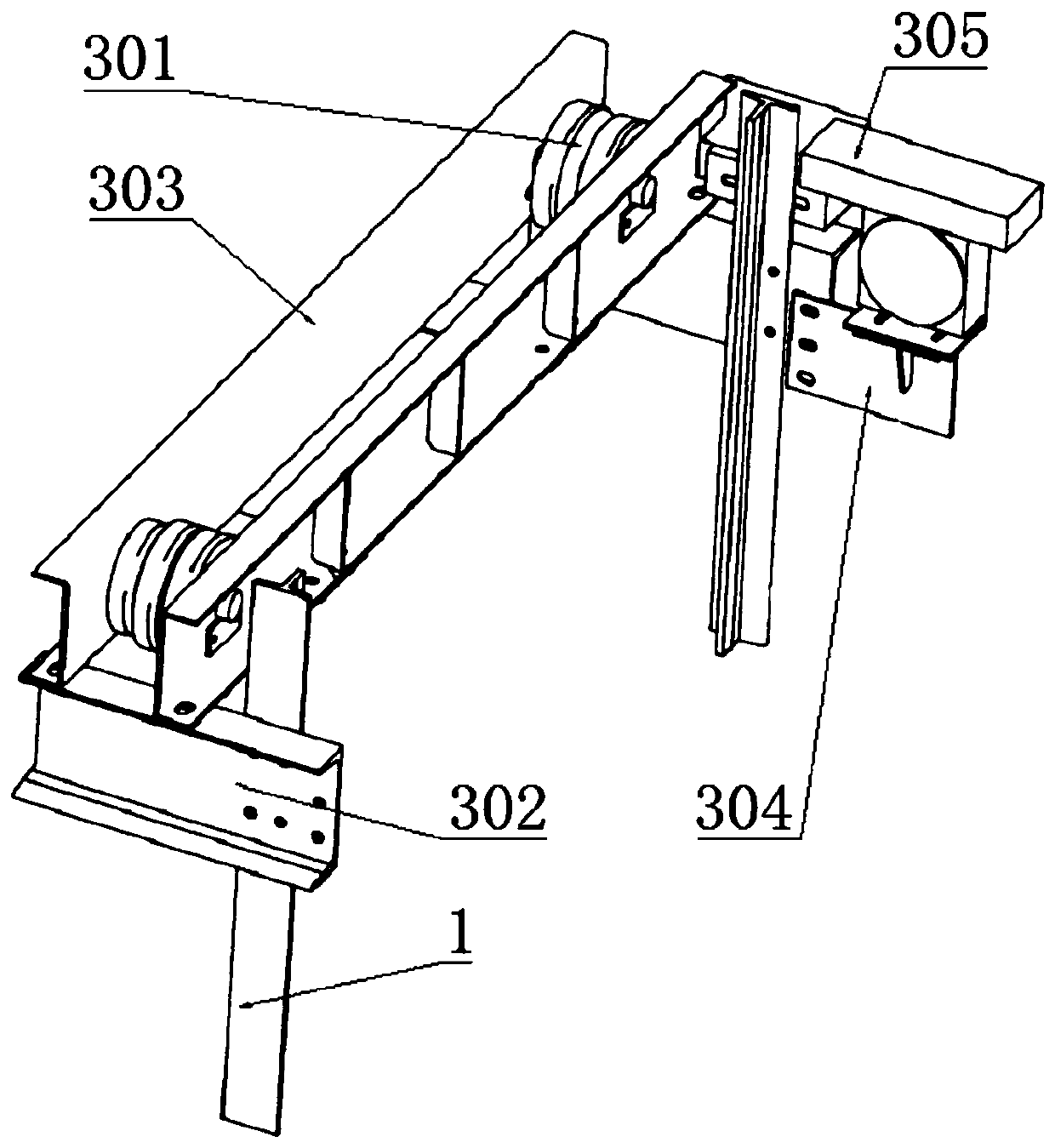

[0041] Unlike the prior art where the anti-sheave device is fixed on the top of the hoistway, the anti-sheave device 3 is fixedly arranged on the upper part of the car guide rail 1 in this embodiment. The anti-sheave device 3 comprises an anti-sheave support beam assembly, and the anti-sheave support beam assembly is fixed on the car guide rail 1 top. The anti-sheave support beam assembly includes two short beams 302 and two long beams 303, the two short beams 302 are horizontally and symmetrically arr...

Embodiment 2

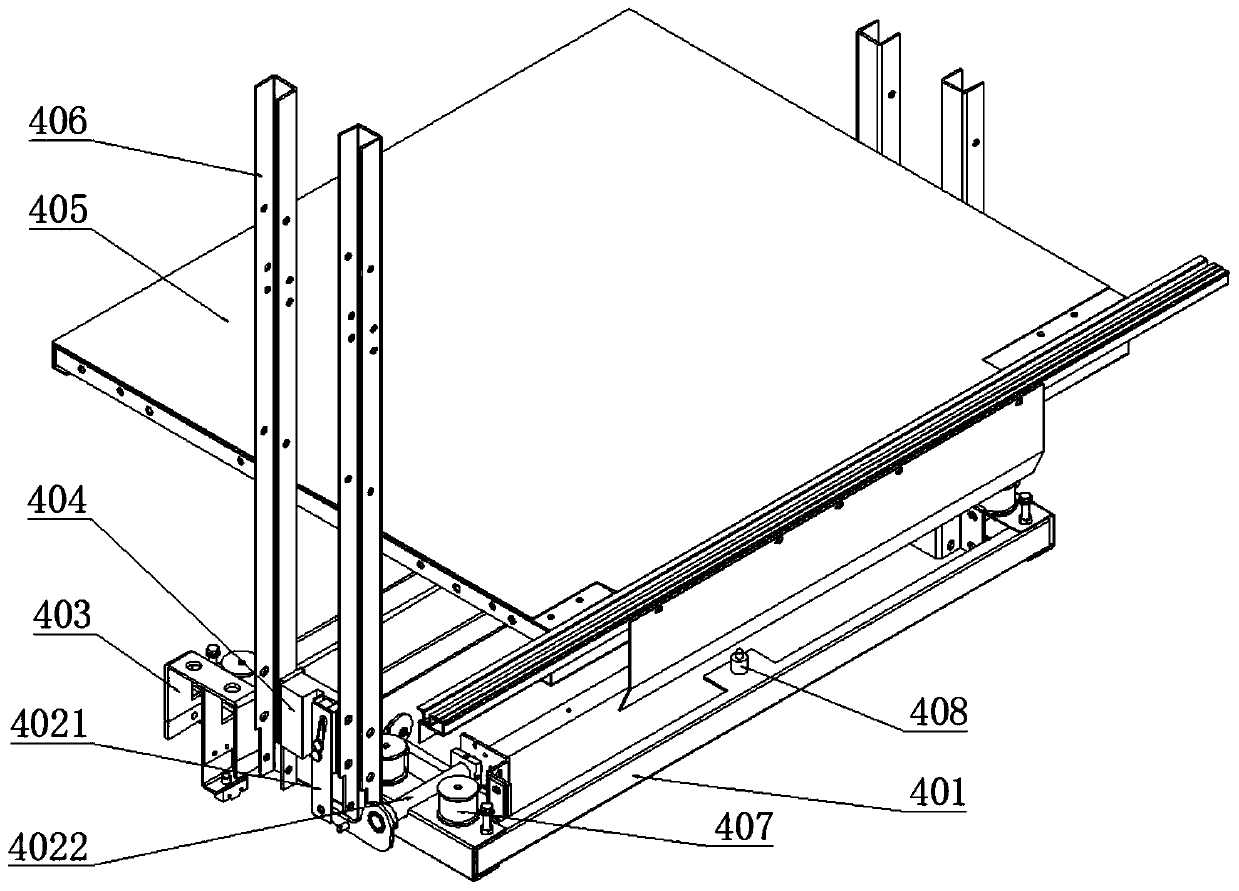

[0049] On the basis of Embodiment 1, two columns 406 are arranged on the left side wall and the right side wall of the car bottom bracket 401, and the car guide shoe 404 is fixed between the two columns 406; the safety gear device includes a safety gear 4021 , safety gear linkage device 4022 ; the safety gear 4021 is set on the car guide shoe 404 , and the safety gear linkage device 4022 is set between the car floor bracket 401 and the car floor 405 . The car rope end plate 403 is arranged as a few characters and the opening is downward; the two arms of the car rope end plate 403 are fixed on the two side walls of the car bracket 401 .

[0050] After adopting the above structure, the structure of the car floor in this embodiment is more compact, which reduces the space occupation in the direction of the car height, thereby reducing the requirement for the depth of the pit, and is suitable for use in the construction of villa elevators.

Embodiment 3

[0052] On the basis of Embodiment 2, the shock-absorbing layer includes four shock-absorbing rubber pads 407 evenly arranged on both sides of the top surface of the car bottom bracket 401, and a weighing device is also arranged on the top surface of the car bottom bracket 401. 408, the shock absorbing rubber pad 407, and the weighing device 408 are all connected with the bottom surface of the car floor 405.

[0053] In this embodiment, an accommodating space is provided between the car floor 405 and the car floor bracket 401, and the shock absorbing layer is arranged in the accommodating space. The shock-absorbing rubber pad 407 is used to reduce the vibration of the elevator during starting, stopping and running, so as to increase the comfort of passengers. The uniform and symmetrical arrangement of the shock-absorbing rubber pads can further improve the shock-absorbing effect, so as to maintain good shock-absorbing performance without affecting the structural strength of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com