Special antibacterial masterbatch for biodegradable garbage bag and preparation method of antibacterial masterbatch

A technology of biodegradable and antibacterial masterbatch, which is applied in the field of preparation of antibacterial masterbatch for biodegradable garbage bags, which can solve the problems of increased cost and poor strength, and save resources , reduce production costs, and protect the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

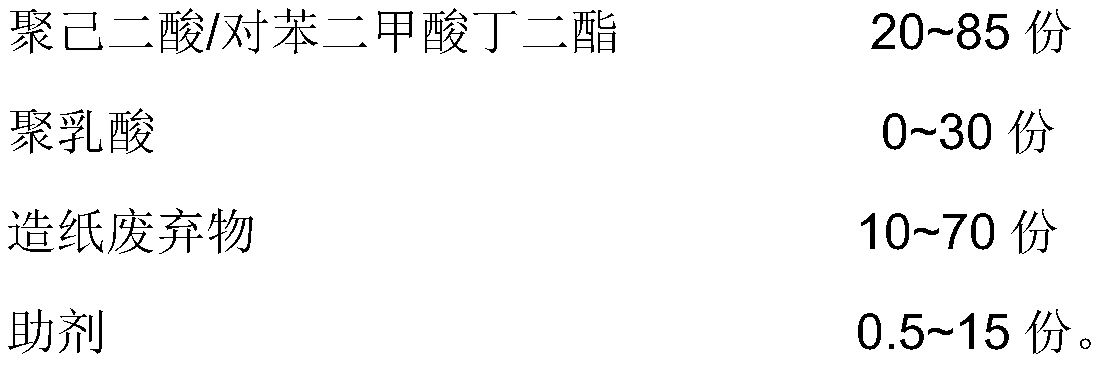

[0031] A special antibacterial masterbatch for biodegradable garbage bags, in parts by mass, comprising the following components:

[0032]

[0033] And, the above recipe proceeds as follows:

[0034] (1) Dry a certain amount of papermaking waste and crush it to 50-500 mesh.

[0035] (2) Place the above-mentioned polybutylene adipate / terephthalate, polylactic acid, papermaking waste, compatibilizer, plasticizer, heat stabilizer, and antioxidant together in a high-speed blender, and The temperature was 60° C., the rotation speed was 250 rpm, and the mixture was mixed for 60 minutes to obtain the primary mixture.

[0036] (3) Place the above primary mixture in a twin-screw extruder to extrude and granulate. The temperature in the first zone to the sixth zone is 200°C, 200°C, 205°C, 210°C, 215°C, 215°C, and the temperature of the head is 215°C. , the screw speed is 300rpm, and the special antibacterial masterbatch for the biodegradable garbage bag is obtained.

[0037] (4) F...

Embodiment 2

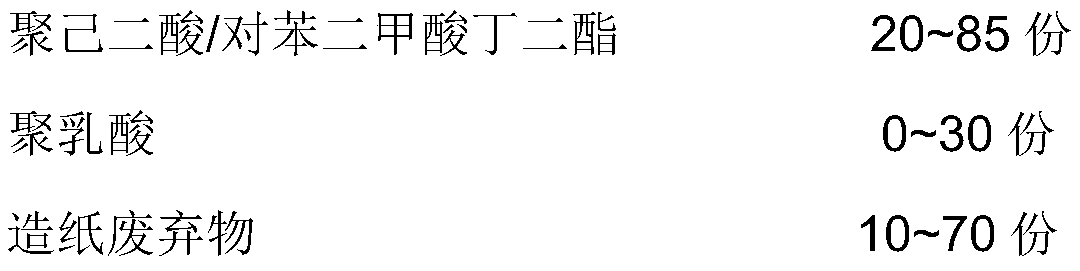

[0039] A special antibacterial masterbatch for biodegradable garbage bags, in parts by mass, comprising the following components:

[0040]

[0041] And, the above recipe proceeds as follows:

[0042] (1) Dry a certain amount of papermaking waste and crush it to 50-500 mesh.

[0043] (2) Place the above-mentioned polybutylene adipate / terephthalate, polylactic acid, papermaking waste, compatibilizer, plasticizer, heat stabilizer, and antioxidant together in a high-speed blender, and The temperature was 60° C., the rotation speed was 250 rpm, and the mixture was mixed for 60 minutes to obtain the primary mixture.

[0044] (3) Place the above primary mixture in a twin-screw extruder to extrude and granulate. The temperature in the first zone to the sixth zone is 200°C, 200°C, 205°C, 210°C, 215°C, 215°C, and the temperature of the head is 215°C. , the screw speed is 300rpm, and the special antibacterial masterbatch for the biodegradable garbage bag is obtained.

[0045] (4) F...

Embodiment 3

[0047] A special antibacterial masterbatch for biodegradable garbage bags, in parts by mass, comprising the following components:

[0048]

[0049]

[0050] And, the above recipe proceeds as follows:

[0051] (1) Dry a certain amount of papermaking waste and crush it to 50-500 mesh.

[0052] (2) Place the above-mentioned polybutylene adipate / terephthalate, polylactic acid, papermaking waste, compatibilizer, plasticizer, heat stabilizer, and antioxidant together in a high-speed blender, and The temperature was 60° C., the rotation speed was 250 rpm, and the mixture was mixed for 60 minutes to obtain the primary mixture.

[0053] (3) Place the above primary mixture in a twin-screw extruder to extrude and granulate. The temperature in the first zone to the sixth zone is 200°C, 200°C, 205°C, 210°C, 215°C, 215°C, and the temperature of the head is 215°C. , the screw speed is 300rpm, and the special antibacterial masterbatch for the biodegradable garbage bag is obtained.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com