A water stop and its construction method

A water-stop, integrated technology, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, and processing of building materials. , uneven quality and other problems, to achieve the effect of enhancing the scope of use and versatility, simple construction methods, and ensuring molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

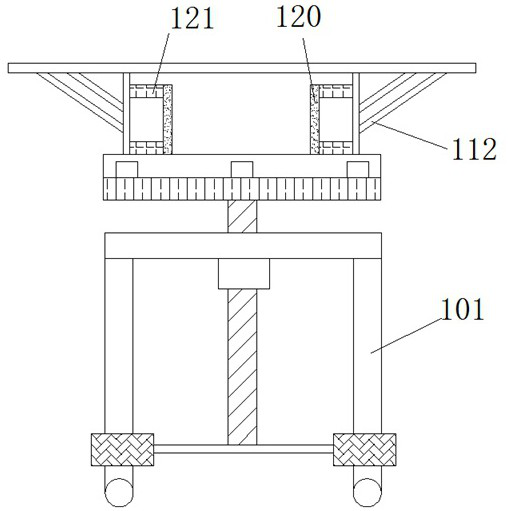

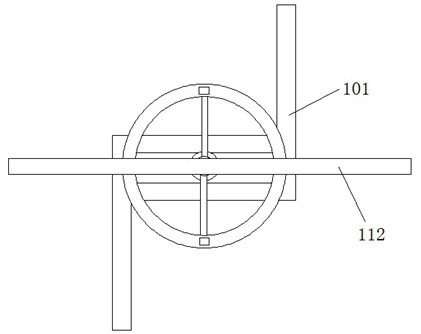

[0036] A water stop sill and its construction method, a water stop sill, including a positioning mold; the positioning mold includes a steel bar stool 101, a screw 108, a support handle 119, a limit piece 112, and a water stop sill template 120;

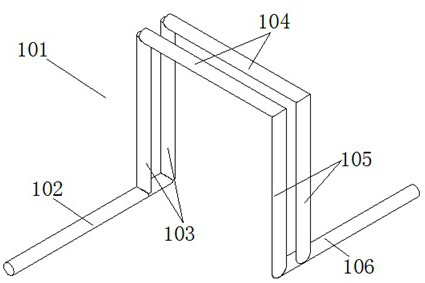

[0037] The steel bar stool 101 includes a first steel bar 102, a second steel bar 103, a third steel bar 104, a fourth steel bar 105, and a fifth steel bar 106; both ends of the third steel bar 104 are connected with the second steel bar 103 and the fourth steel bar 105 respectively , the second steel bar 103 is parallel to the fourth steel bar 105, the end of the second steel bar 103 away from the third steel bar 104 is connected with the first steel bar 102, and the end of the fourth steel bar 105 away from the third steel bar 104 is connected with the fifth steel bar 106 to form a In one body, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com