Water jet dense comb-shaped drilling type coal seam gas outburst reduction and pre-drainage treatment method for roadway to be excavated

A coal seam gas and water jet technology, which is used in gas discharge, earthwork drilling, mining equipment, etc., can solve the problems of limited number of branch holes, broken coal seam, and long construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

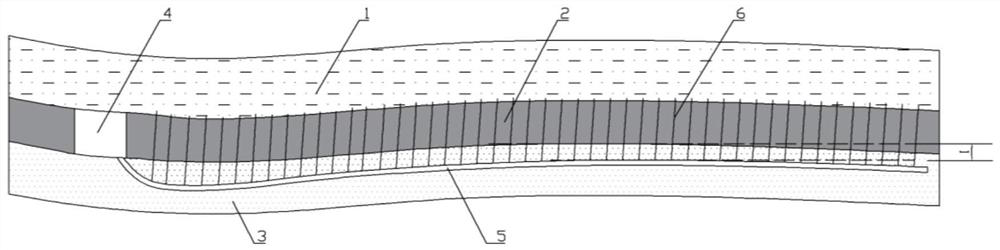

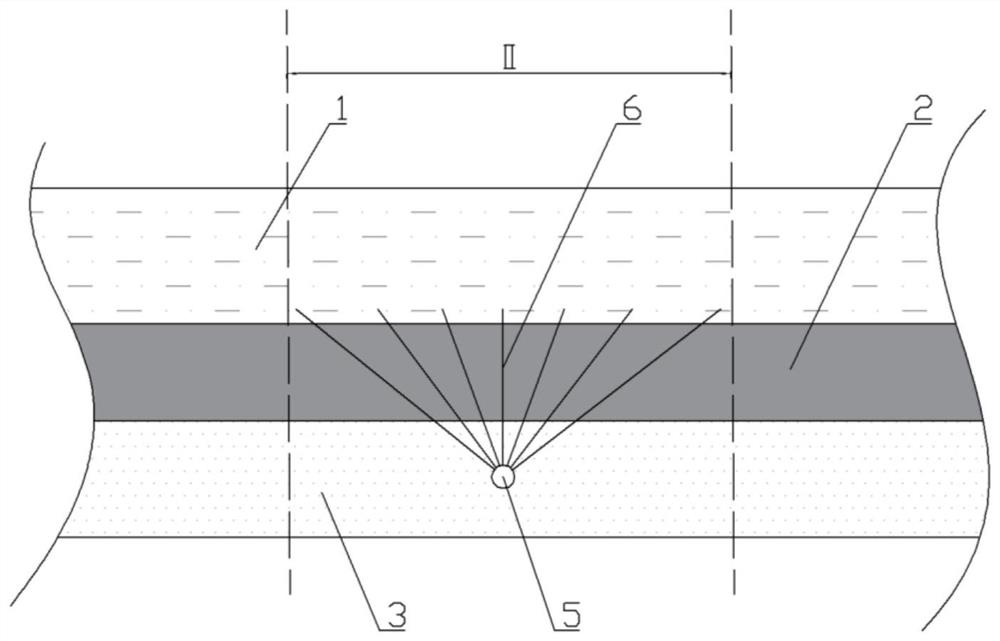

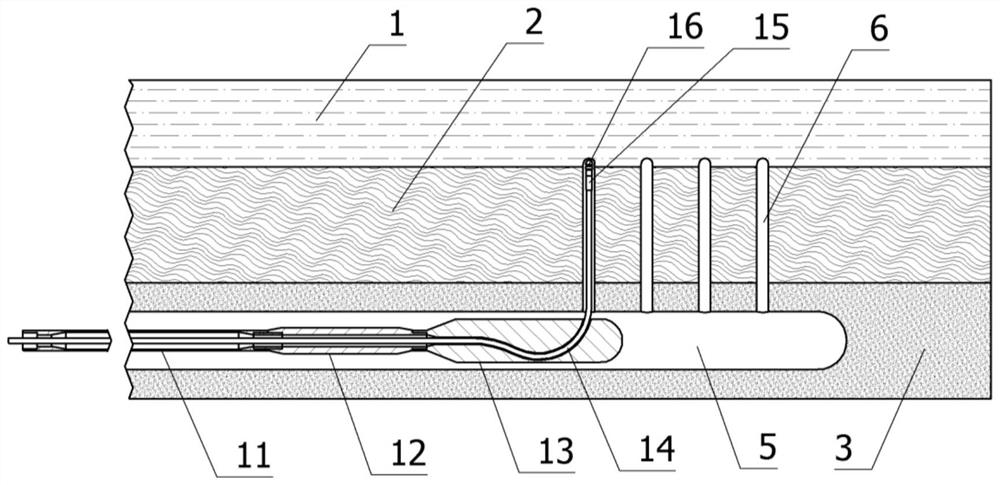

[0035] see figure 1 and 2 , shows the water jet intensive comb-shaped drilling type coal seam gas outburst pre-drainage treatment method to be excavated.

[0036] The water jet intensive comb-shaped drilling type coal seam gas outburst elimination and pre-drainage treatment method includes the following steps:

[0037] Step 1: Construction forms a directional long borehole, which may include the following sub-steps:

[0038] a. Determine the position of the directional long drilling, such as figure 1 As shown, the position of the directional long borehole 5 is determined according to the regional stratum data of the roadway to be excavated. 2 extends below the coal seam roof 1, the coal seam floor 3 extends below the coal seam 2 of the roadway to be excavated, the directional long borehole 5 is located in the coal seam floor 3, preferably in a relatively stable rock formation of the coal seam floor 3, the The direction of extension of the directional long borehole 5 is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com