Explosion-proof pipe

A technology of pipes and corrugated pipes, applied in the field of pipes conveying water medium, can solve problems such as bursting and leaking, achieve the effects of eliminating gaps, increasing the strength of seals and connections, and avoiding pipe bursts and pull-off leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Assume: The distance between the two threaded joints of the initial corrugated pipe section of type A is 0.5 meters, and the length when all the bending angles of the coils are fully straightened is 0.75 meters, that is, the maximum extension length is 0.25 meters.

[0011] Suppose: the length of the straight pipe section is 0.25, 0.50, 0.75, 1.00, 1.25, 1.50, 1.75, 2.00, 2.25, 2.50, 2.75 meters, a total of eleven kinds of length specifications.

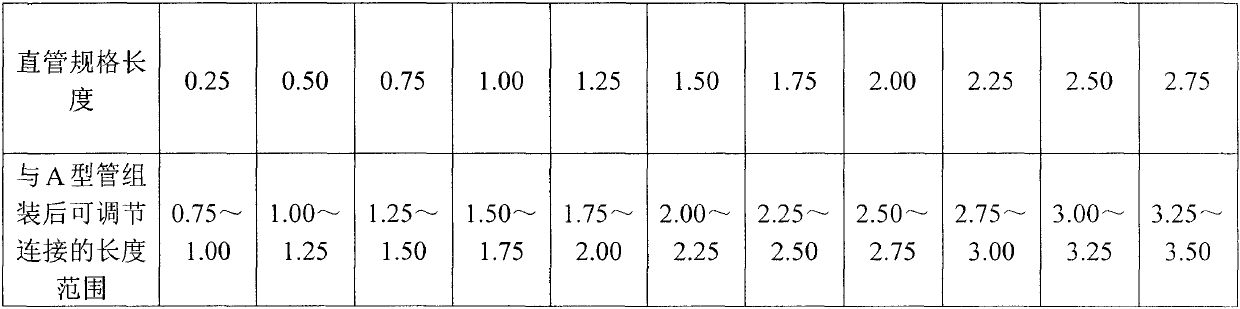

[0012] By assembling A-type corrugated pipe sections with eleven types of straight pipes, the lengths of pipe sections that can be obtained are shown in Table 1.

[0013] Table 1. The length range of the adjustable connection between the A-type bellows section and 11 kinds of length specifications straight pipe assembly

[0014]

[0015] Therefore, the application of this pipeline not only has the explosion-proof function, but also can be adjusted to any length of pipe section by directly selecting or assembling the corruga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com