Gas exhaust valve type carbon dioxide cracking tube and parallel cracking device thereof

A technology of carbon dioxide and cracking tubes, which is applied in the direction of weapon accessories, blasting cylinders, blasting, etc., and can solve the problems of large-scale foreign operations that are difficult to meet blasting requirements, low blasting force, and low power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

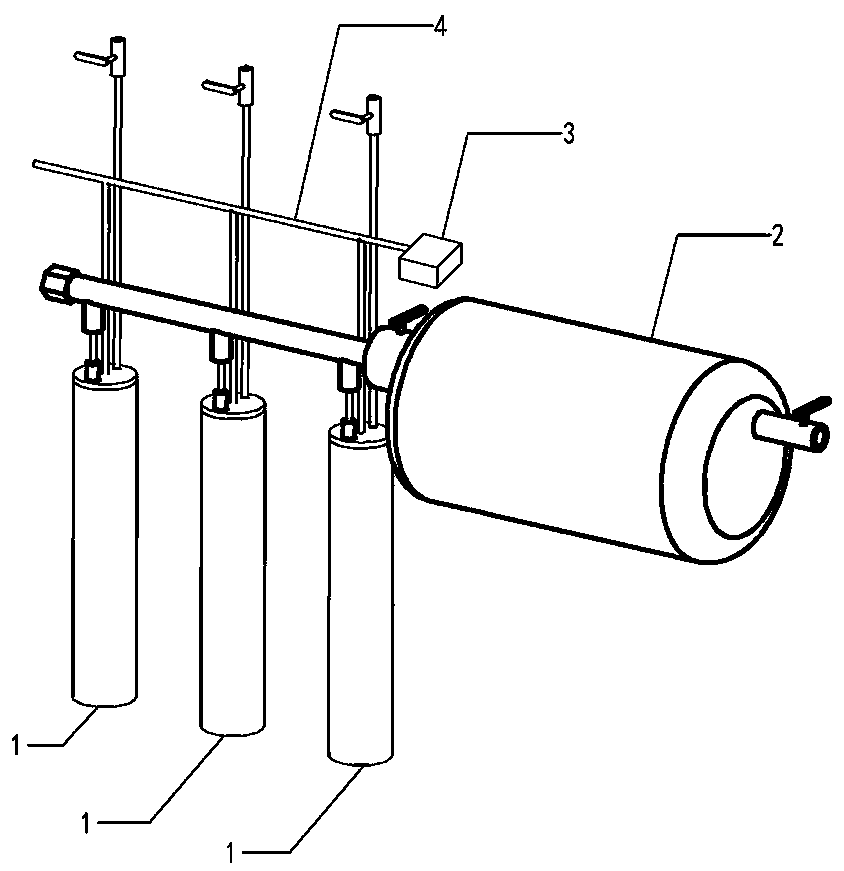

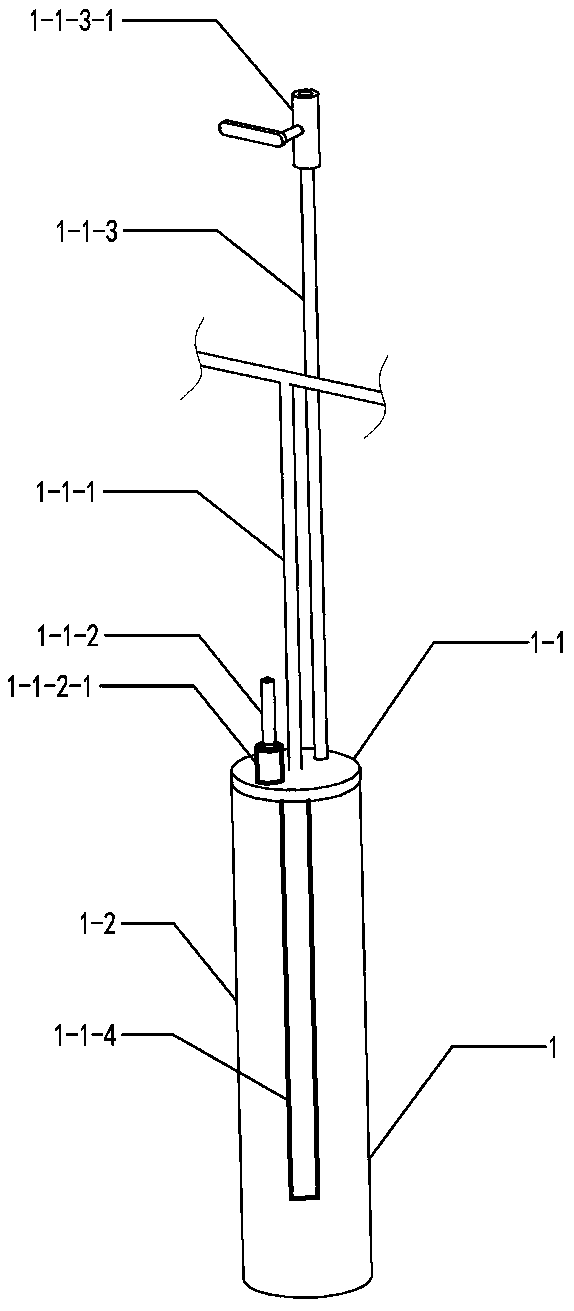

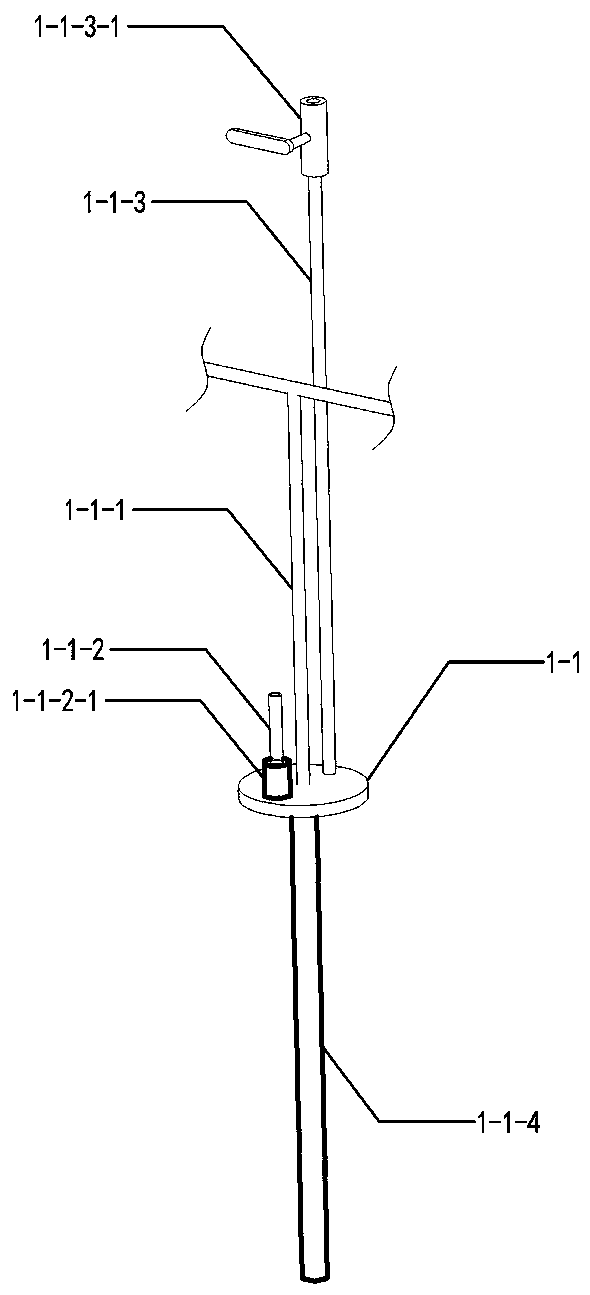

[0023] It can be seen from the content of the invention that an exhaust valve type carbon dioxide cracking tube and its parallel cracking device are composed of a venting type cracking tube 1, a gas parallel device 2, a detonator 3, and an electronic fuze line 4; The gas cracking tube 1 consists of a sealing plate 1-1, a tube body 1-2, an electronic fuze 1-1-1, an air intake pipe 1-1-2, an air intake check valve 1-1-2-1, an exhaust Pipe 1-1-3, exhaust pipe valve 1-1-3-1, composition, and on sealing plate 1-1, be provided with air inlet hole 1-1-5, fuze hole 1-1-6, exhaust hole 1-1-7; the electronic fuze 1-1-1 passes through the fuze hole 1-1-6 to connect with the detonator 1-1-4; the air intake check valve 1-1-2-1 Installed between the air intake hole 1-1-5 and the air intake pipe 1-1-2; the lower end of the exhaust pipe 1-1-3 is welded to the mouth of the exhaust hole 1-1-7, and the exhaust pipe valve 1-1-3-1 is installed on the upper end of the exhaust pipe 1-1-3; the gas p...

Embodiment 2

[0050] In order to realize the exhaust function of the cracking tube in the present invention, an exhaust pipe 1-1-3 is provided on the exhausting cracking tube 1 .

Embodiment 3

[0052] In order to realize rapid removal of impurities in the gas, the present invention designs the inlet pipe 1-1-2 and the exhaust pipe 1-1-3 at the same end of the exhaust-type cracking pipe 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com