Electric brush structure installed in slide wire current collector

A current collector and sliding contact wire technology, applied in the field of brush structure, can solve the problems that the brush is easily skewed to one side, difficult to ensure uniformity, unfavorable for stable and reliable power supply, etc., and achieves convenient and reliable installation and fixation. Smooth and smooth telescopic motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

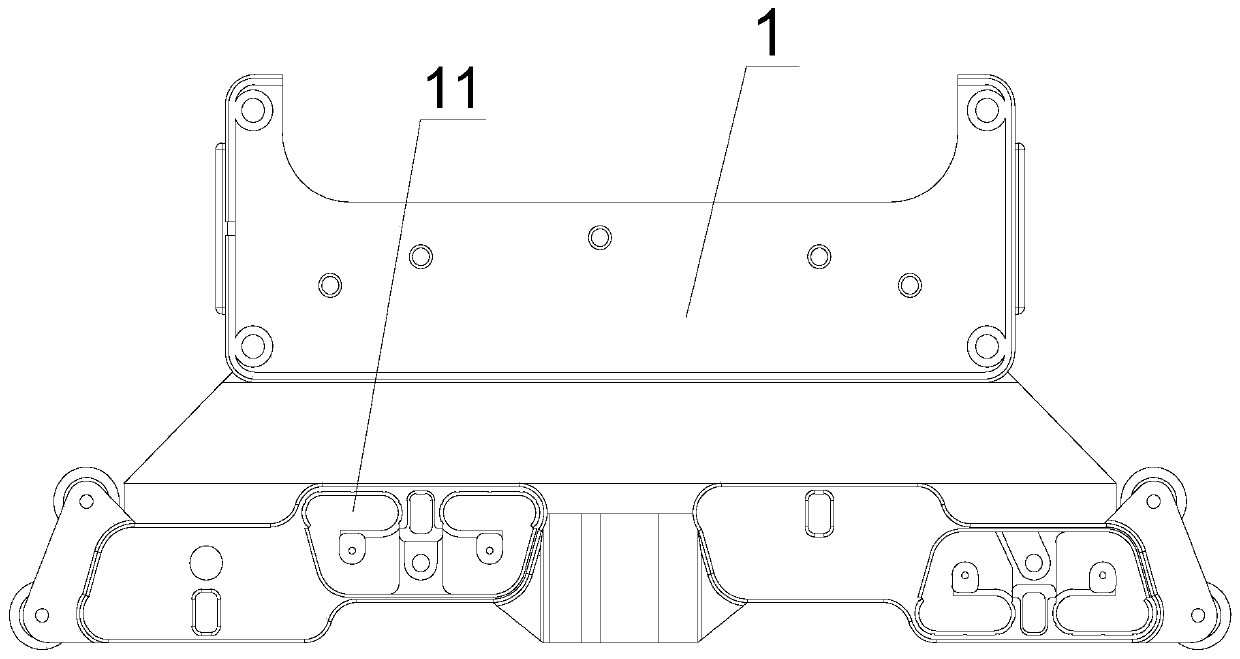

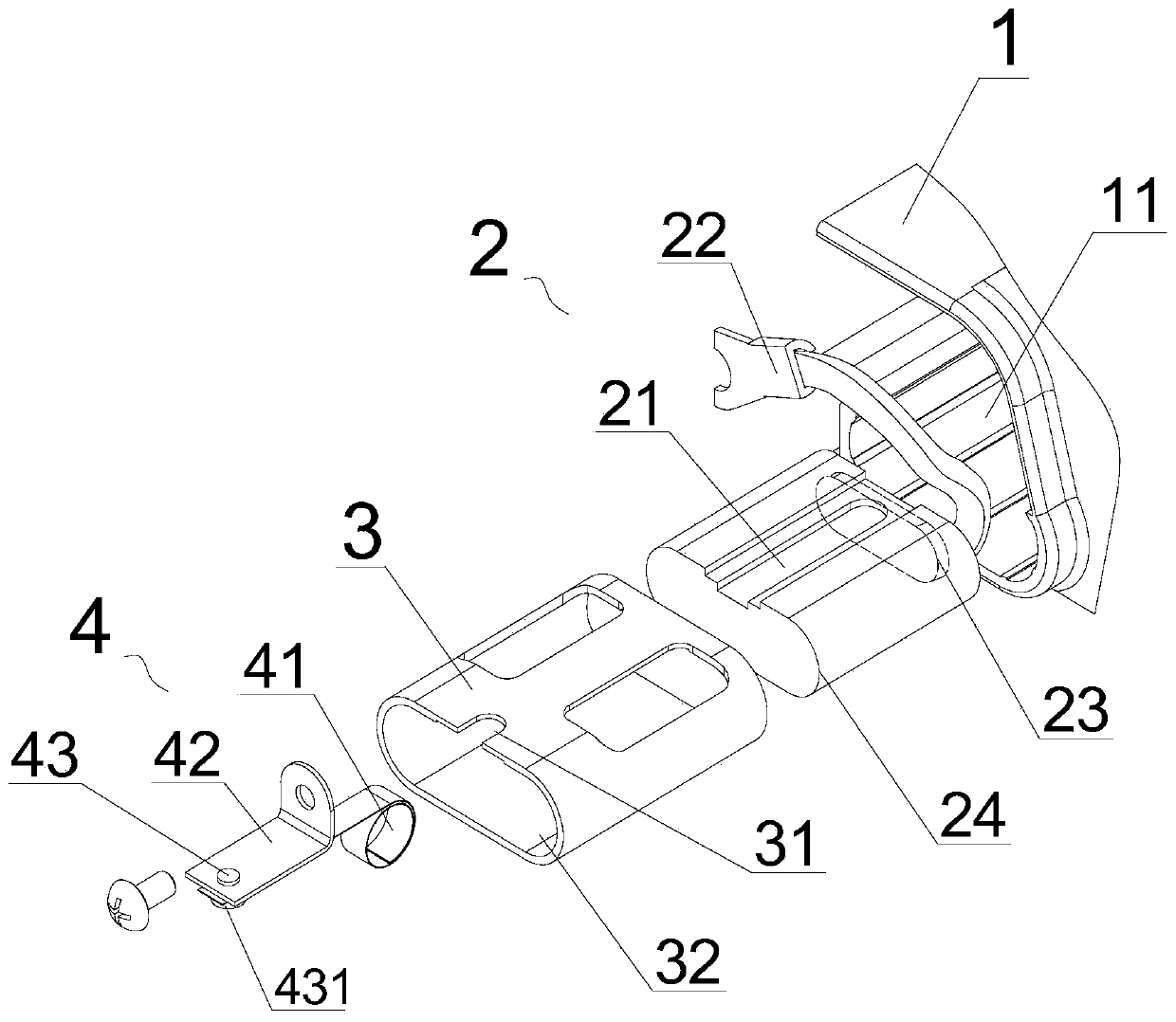

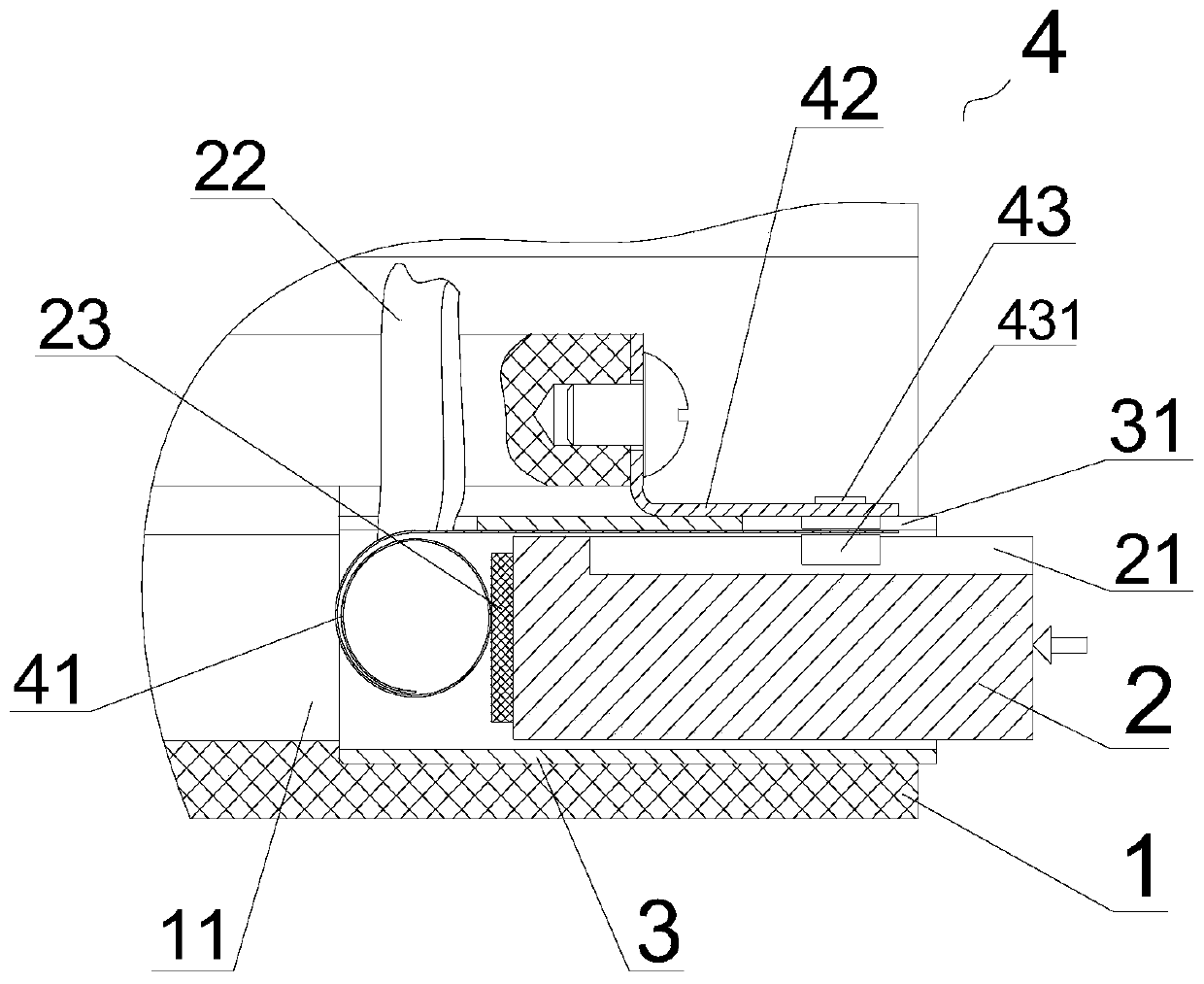

[0033] see Figure 1~5 As shown, a brush structure installed in a trolley line collector according to the present invention includes a collector housing 1 and a brush 2 installed in the collector housing 1, and the collector housing 1 There is more than one brush fixing groove 11 in the center, and a guide brush holder 3 is fixed in the brush fixing groove 11, and an open groove 31 is arranged on one side of the guide brush holder 3, and the open groove 31 The middle card is provided with a constant force driving spring assembly 4, and the constant force driving spring assembly 4 includes a constant force coil spring 41 and an L-shaped fixed bracket 42, and the end of the constant force coil spring 41 and the L-shaped fixed bracket One end of 42 is riveted together by rivet 43, the constant force coil spring 41 is placed in the cavity of the guide brush holder 3, and the other end of the L-shaped fixing bracket 42 is fixed in the collector housing 1 The electric brush 2 is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com