Industrial robot collision preventing method

A technology for industrial machines and robots, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of increased complexity of detection algorithms and increased time complexity of collision detection algorithms, so as to reduce the calculation amount of intersection detection and avoid collisions. , the program is simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

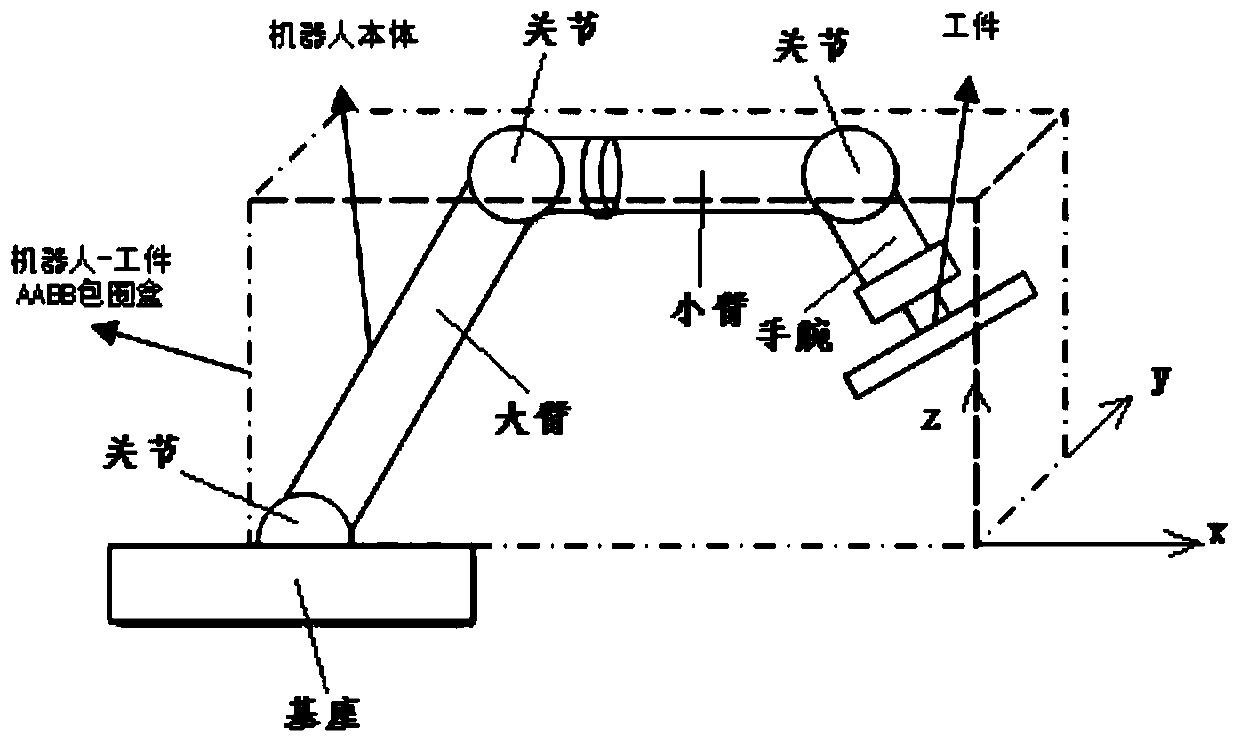

[0044]Embodiment 1 is a method for detecting whether the industrial robot collides with the clamped workpiece or external tooling when an industrial robot consisting of a base, a large arm, a small arm, and a wrist moves to clamp a workpiece.

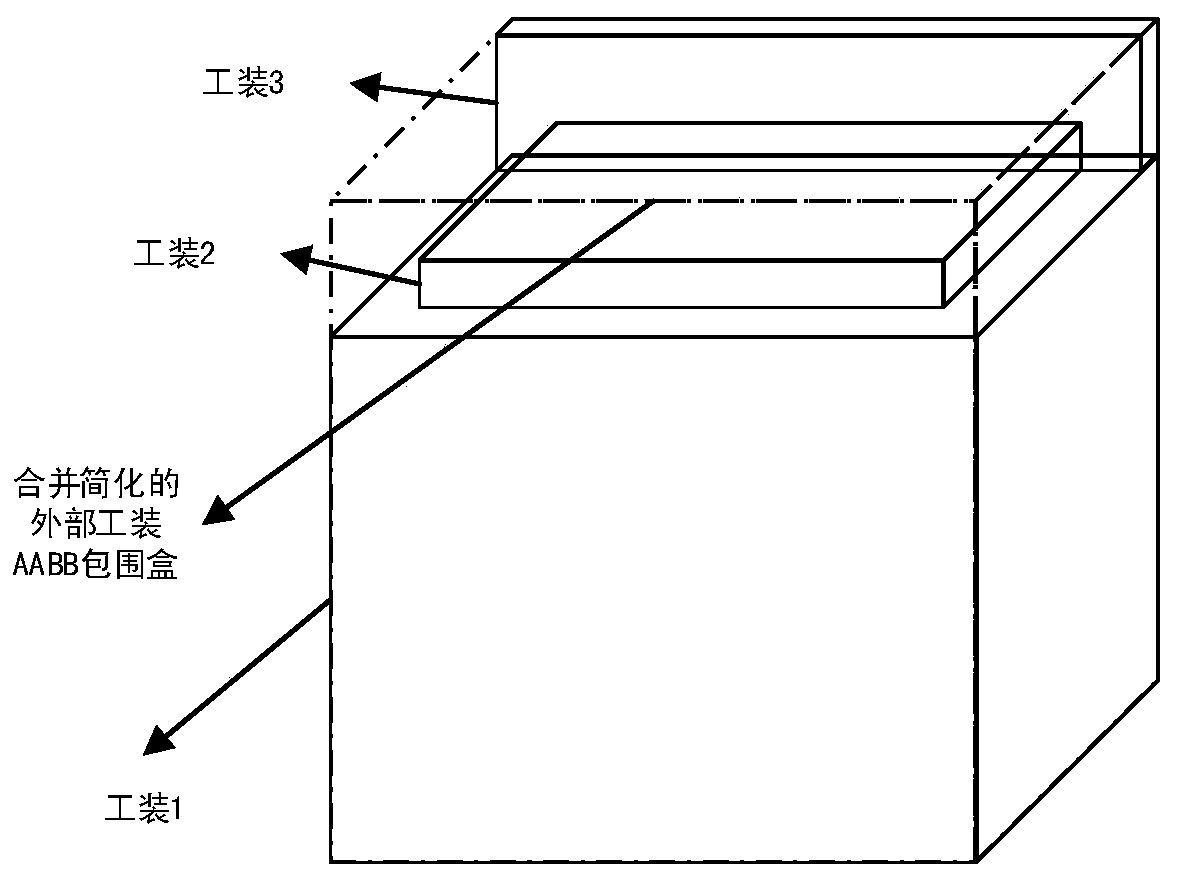

[0045] Assume that the current calculation time of the movement of the workpiece clamped by the robot is t=50ms, and the control calculation period is 10ms; there are three external toolings, namely external tooling 1, external tooling 2 and external tooling 3.

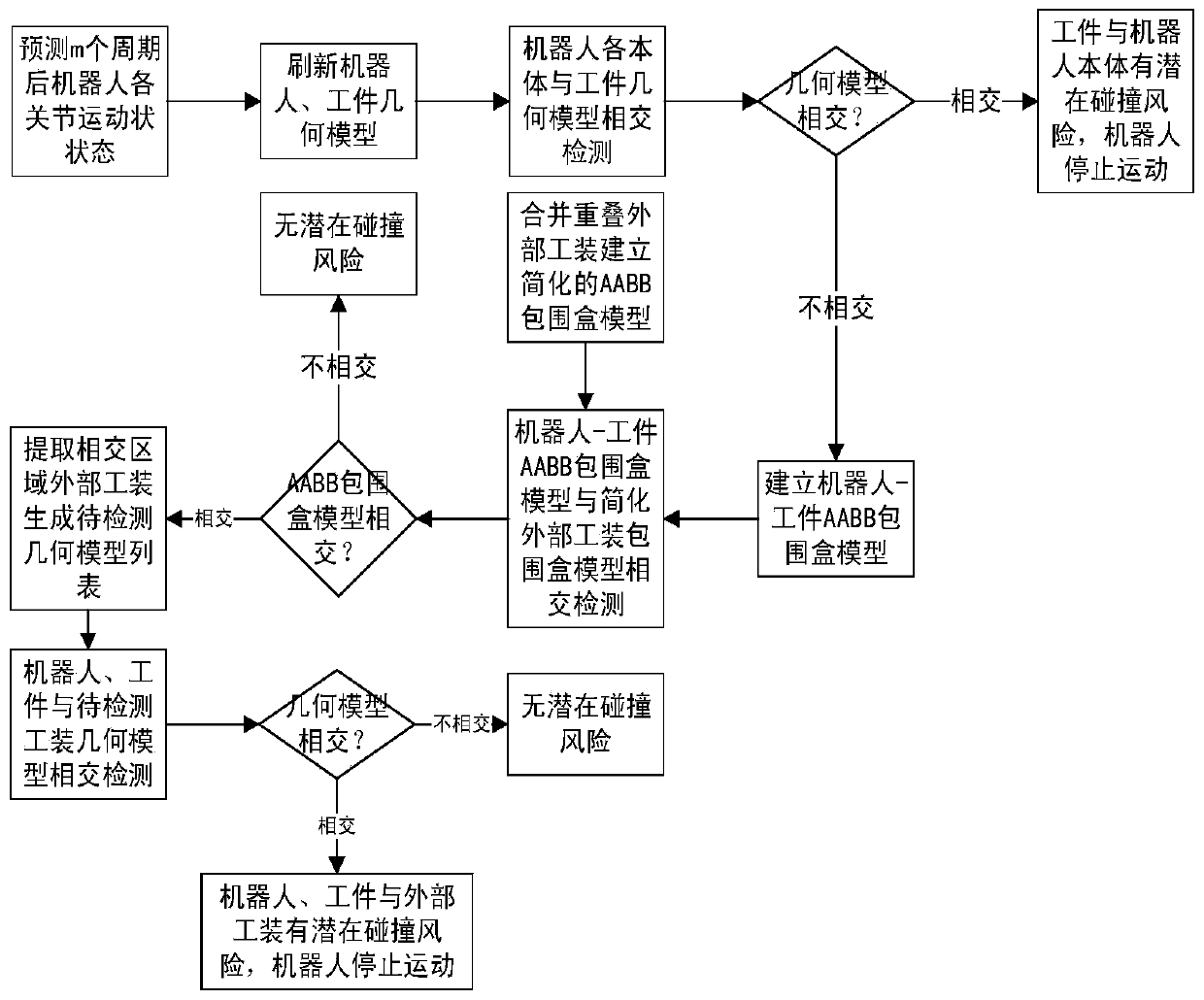

[0046] refer to figure 1 , the robot anti-collision method of Embodiment 1 includes the following steps connected in sequence:

[0047] Step 1.1, establish the geometric model of the robot, the workpiece geometric model and the external tooling geometric model in the initial state;

[0048] The geometric model of the robot and the workpiece is a geometric model defined by the mechanical properties of the robot and the workpiece, that is, a set of three-dimensional graphics com...

Embodiment approach 2

[0081] The method of embodiment 2 is basically the same as that of embodiment 1, the only difference is that the compensation period parameter γ is introduced in the method of confirming the forecast period m, m=t stop / Δt+γ; where γ is the compensation period parameter.

[0082] In this embodiment, assuming that the compensation cycle parameter γ is 1, the calculation method of the cycle m is m=10 / 2+1=6. The number of m cycles in Embodiment 2 is 6, and compared with Embodiment 1, the number of m cycles is increased by one. That is to say, in Embodiment 2, at the current moment, it is possible to predict whether a potential collision occurs at the time t=50+6*10=110ms, while in Embodiment 1, it is only possible to predict whether a potential collision occurs at the time t=50+5*10=100ms . That is to say, the method in Embodiment 2 can predict the risk of collision earlier than Embodiment 1, provide more sufficient stopping time, and a longer stopping distance.

[0083] Accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com