Deposit sediment core drilling process suitable for seabed rope core drilling machine

A coring rig and sediment technology, applied in the direction of extracting undisturbed core devices, automatic control systems for drilling, drilling equipment, etc., can solve the problem of high probability of hole collapse, difficult monitoring and remediation, and failure to lower the inner tube of wireline coring, etc. problem, to achieve the effect of high heart rate and low disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

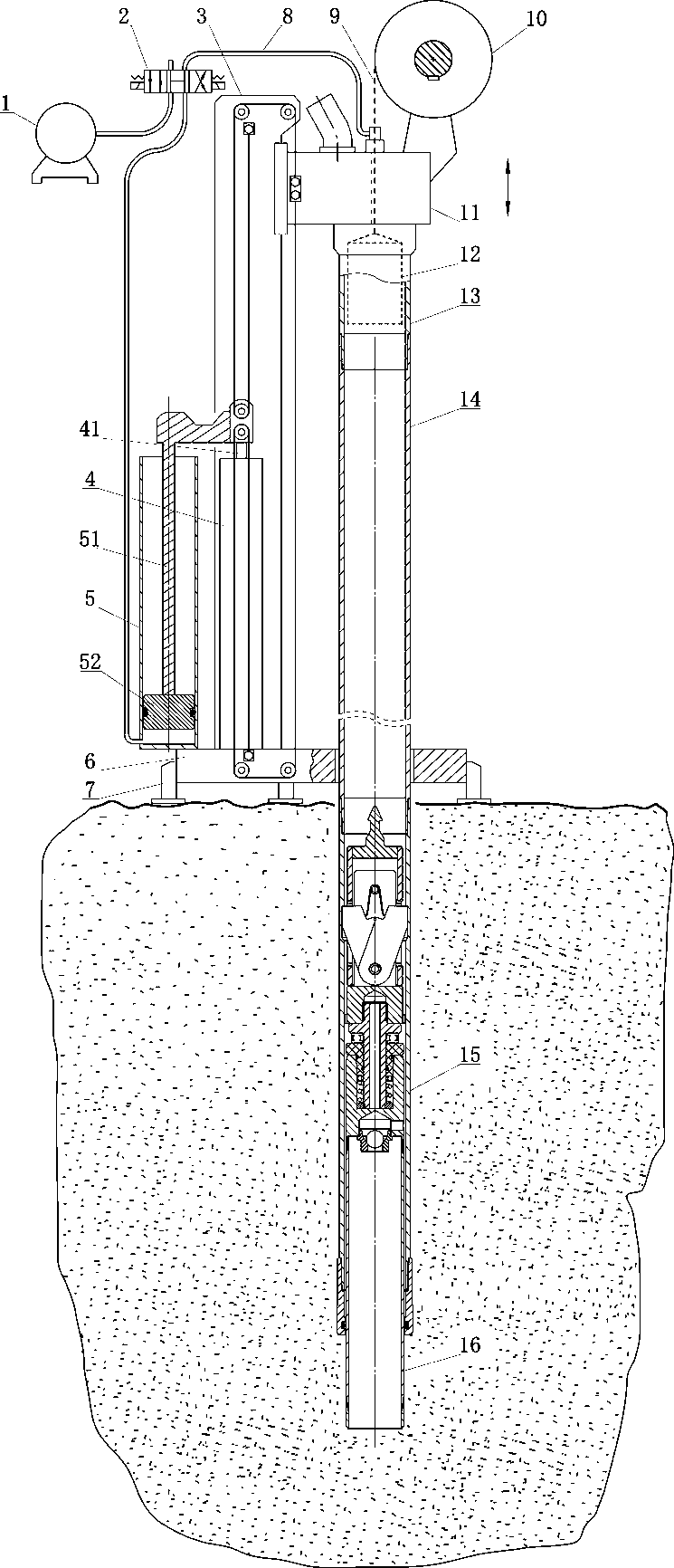

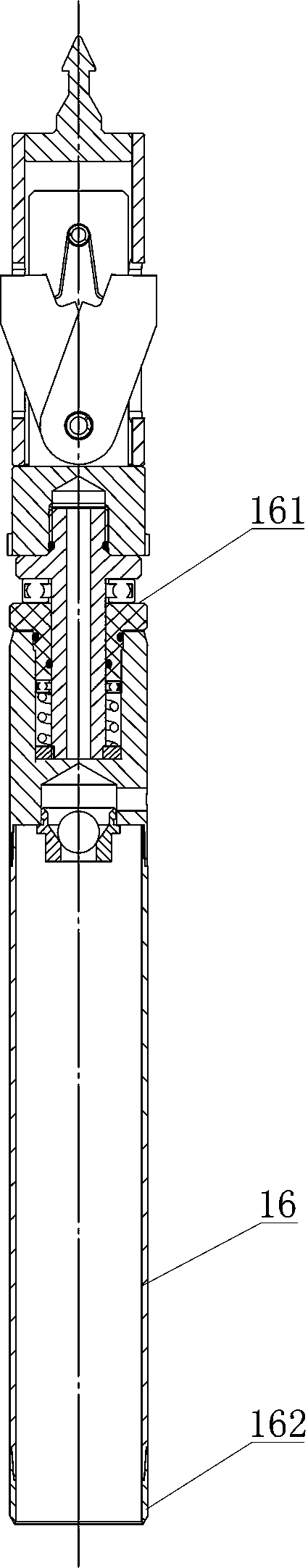

[0037] Such as figure 1 and figure 2As shown, the coring device adopted in the present invention comprises a submarine cable coring rig, a plurality of special drill rods 14 for cable coring, a plurality of cable coring inner tubes 16, and a cable coring outer tube drilling tool 15. The coring rig is equipped with a high-pressure seawater flushing pump 1, a seawater suction cylinder 5, and a flushing water reversing valve 2. The water outlet of the high-pressure seawater flushing pump 1 and the rodless cavity inlet of the seawater suction cylinder 5 pass through the flushing water reversing valve. 2. It communicates with the inner hole of the active drill pipe 13 on the drilling power head 11 of the submarine cable coring rig. The flushing water reversing valve 2 can switch the inner hole of the drill pipe 14 to the water outlet of the high-pressure seawater flushing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com