A valve guide and its manufacturing method

A valve guide and manufacturing method technology, which is applied to lift valves, mechanical equipment, valve devices, etc., can solve the problems of difficult valve guide processing, increased valve guide wear, and increased oil consumption, so as to avoid emission of particulate pollutants, The effect of reducing frictional work and optimizing emission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

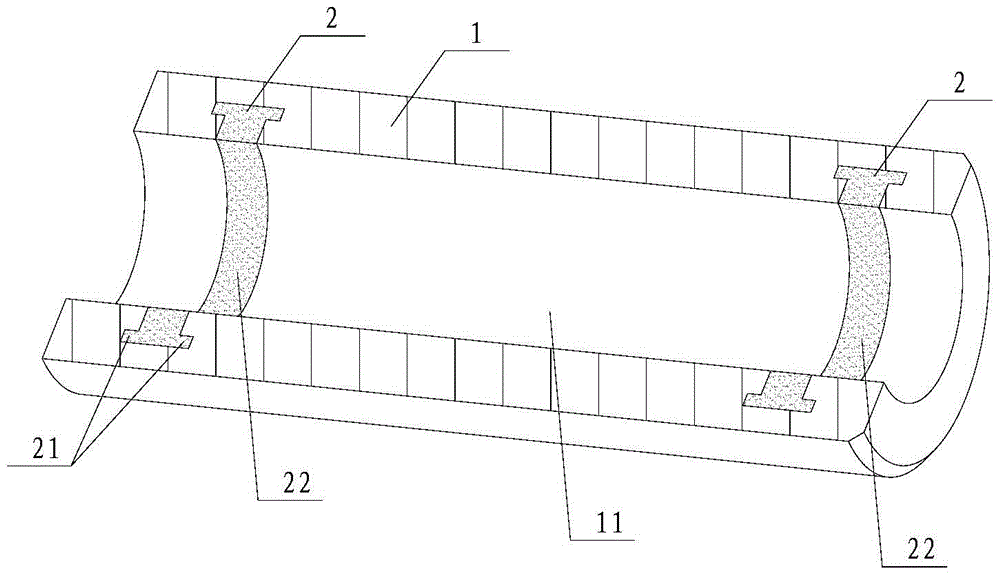

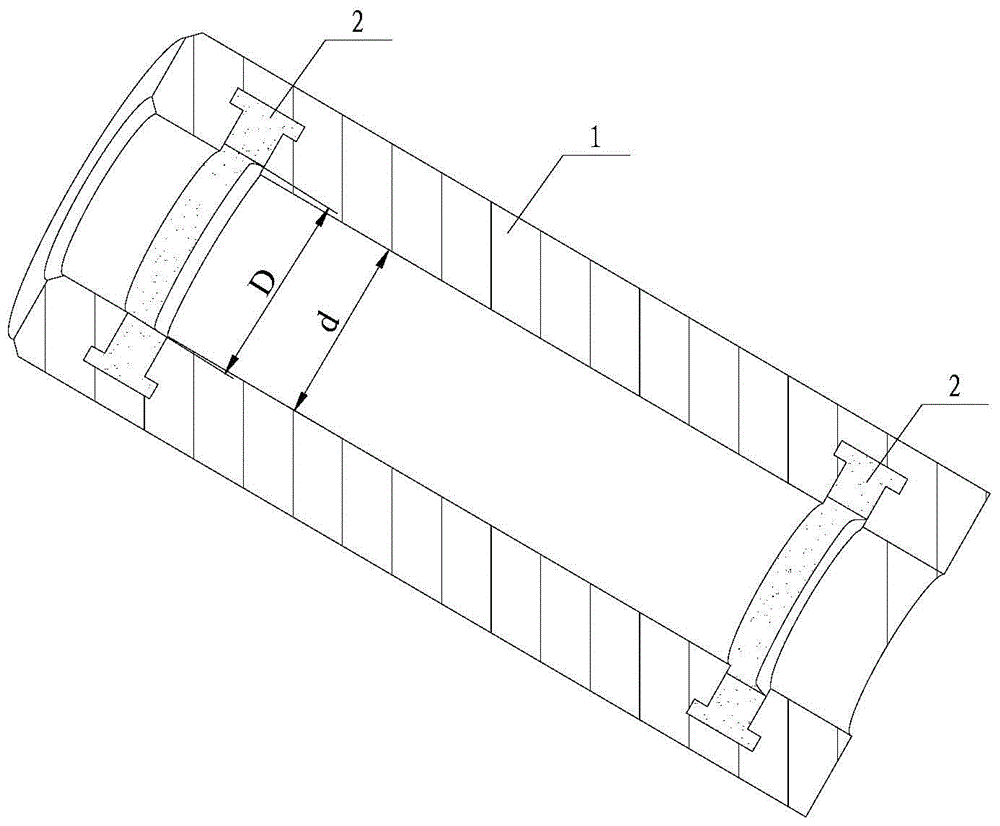

[0036] See figure 1 , this figure is a schematic diagram of the overall structure of the valve guide described in the first embodiment. In order to clearly show the core design of this solution, this figure is an axial section of the inspection tool for measuring the height of the cone surface of the valve seat ring described in this embodiment. Schematic diagram of the working state, which is expressed in the form of axial section.

[0037] The valve guide is composed of two main parts: the valve guide body 1 and the porous high-temperature resistant insert 2 embedded in the inner wall of the valve guide body 1, and the porous high-temperature resistant insert 2 is formed with the valve guide body 1 and the valve stem (Fig. not shown in ) the internal cylindrical surface of the clearance fit; that is to say, the inner peripheral surface 22 of the porous high temperature resistant insert 2 is the same diameter as the inner peripheral surface 11 of the valve guide body 1, and t...

Embodiment 2

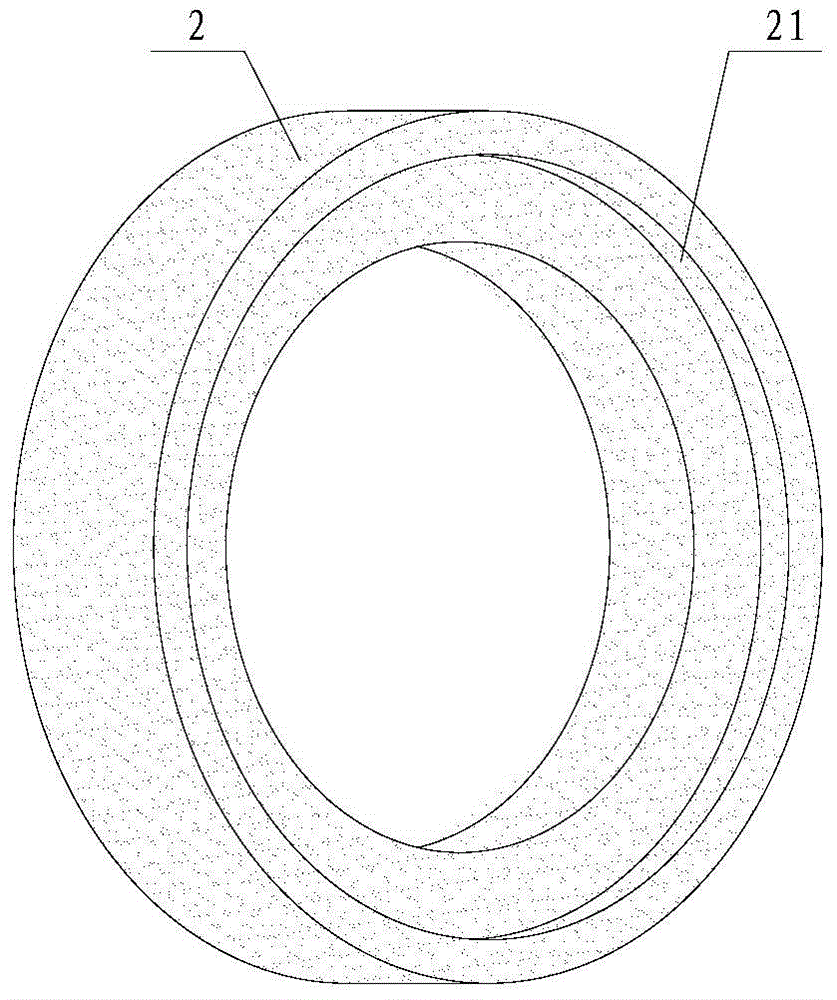

[0051] See Figure 4 , which is a schematic axial cross-sectional view of the porous high-temperature resistant insert shown in the second embodiment.

[0052] Compared with the first embodiment, the porous high-temperature resistant insert 2' of this solution is also annular, the only difference is that the porous high-temperature resistant insert 2' of this solution is made of silicon nitride porous ceramic material , the limiting part 21' adopts a different structure, such as Figure 4 As shown, in its axial section, the limiting portion 21 ′ is formed by extending from both axial sides of the body of the porous high-temperature resistant insert 2 ′, and is generally triangular in shape.

Embodiment 3

[0054] See Figure 5 , which is a schematic axial cross-sectional view of the porous high-temperature resistant insert shown in the third embodiment.

[0055] Compared with the first and second embodiments, the porous high-temperature resistant insert 2" described in this solution is also annular, the only difference is that the porous high-temperature resistant insert 2" described in this solution is made of alumina porous ceramics , the number of setting of the limit part 21" is different. For example Figure 5 As shown, in its axial section, the limiting portion 21" protrudes from two bosses on both axial sides of the body of the porous high-temperature resistant insert 2".

[0056] Same as the first embodiment, the porous high-temperature resistant inserts in the second and third embodiments can also be pre-embedded in the casting sand mold of the valve guide, cast and solidified by molten iron. I won't repeat them here.

[0057] In addition, it should be noted that, in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com