Anti-blockage rubber crushing device for waste tire recycling

A technology of crushing device and waste tires, applied in the direction of plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of lack of secondary utilization, laborious, difficult cleaning, etc., so as to avoid incomplete crushing and improve dredging efficiency. , Strengthen the effect of conveying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

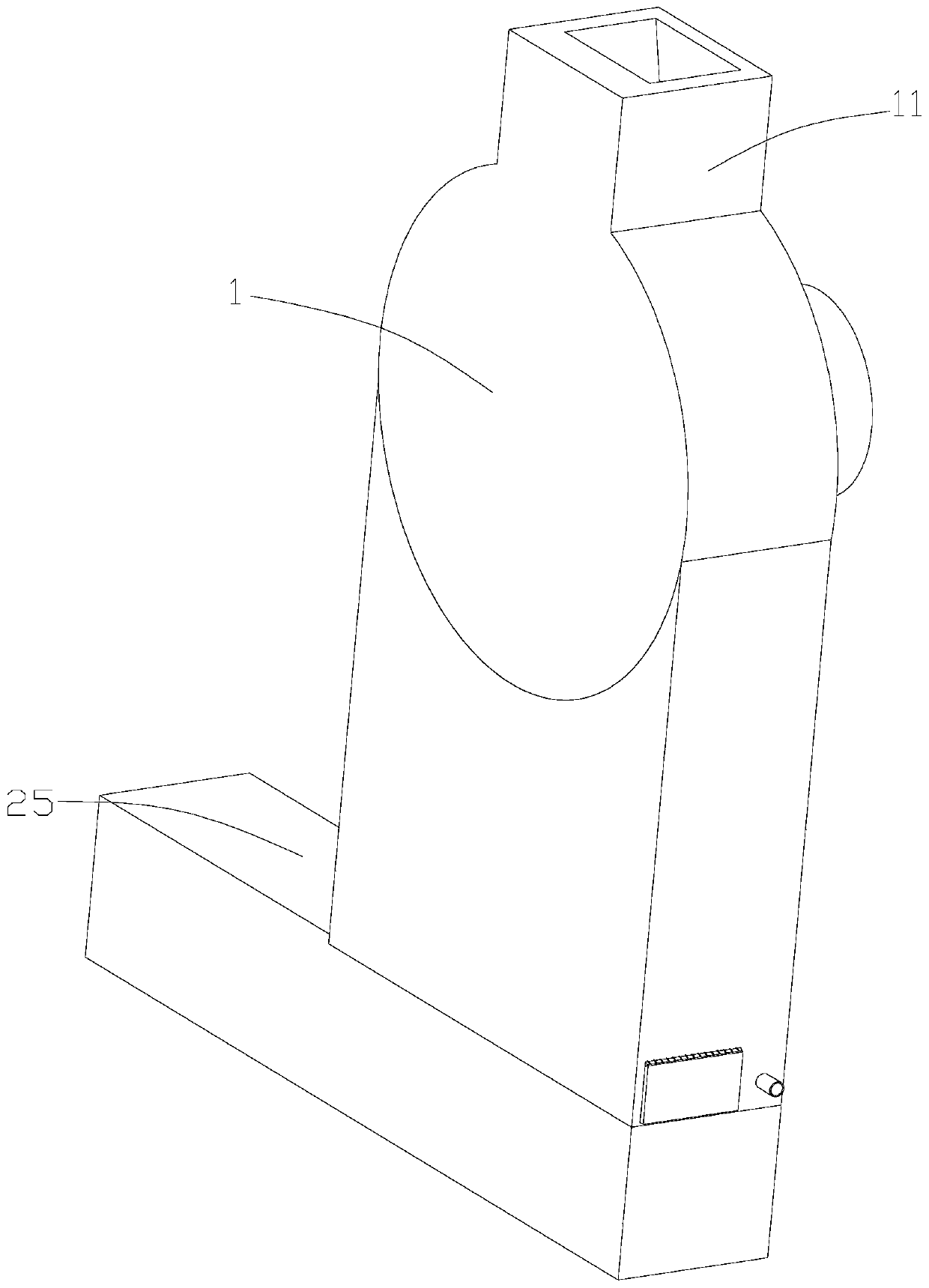

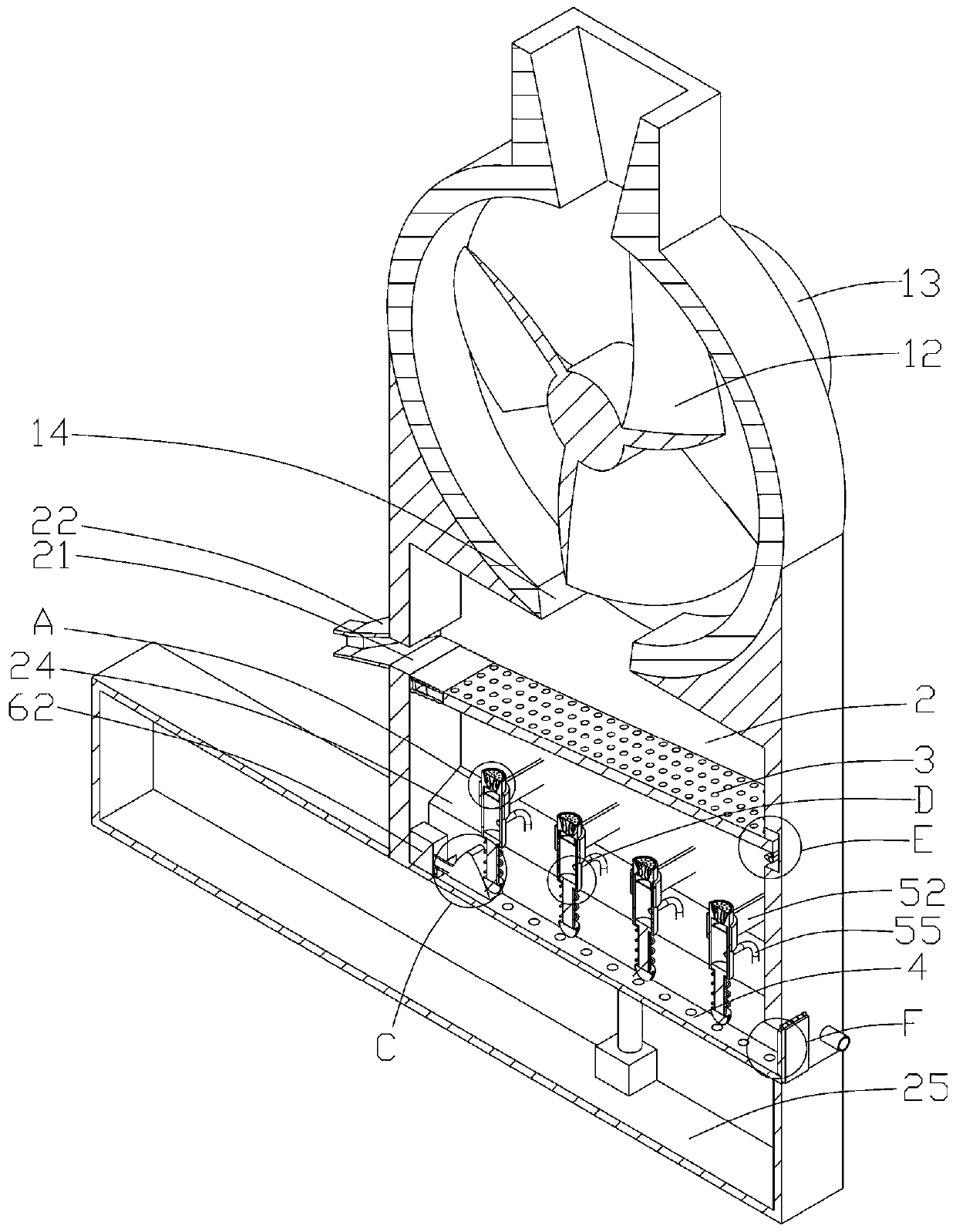

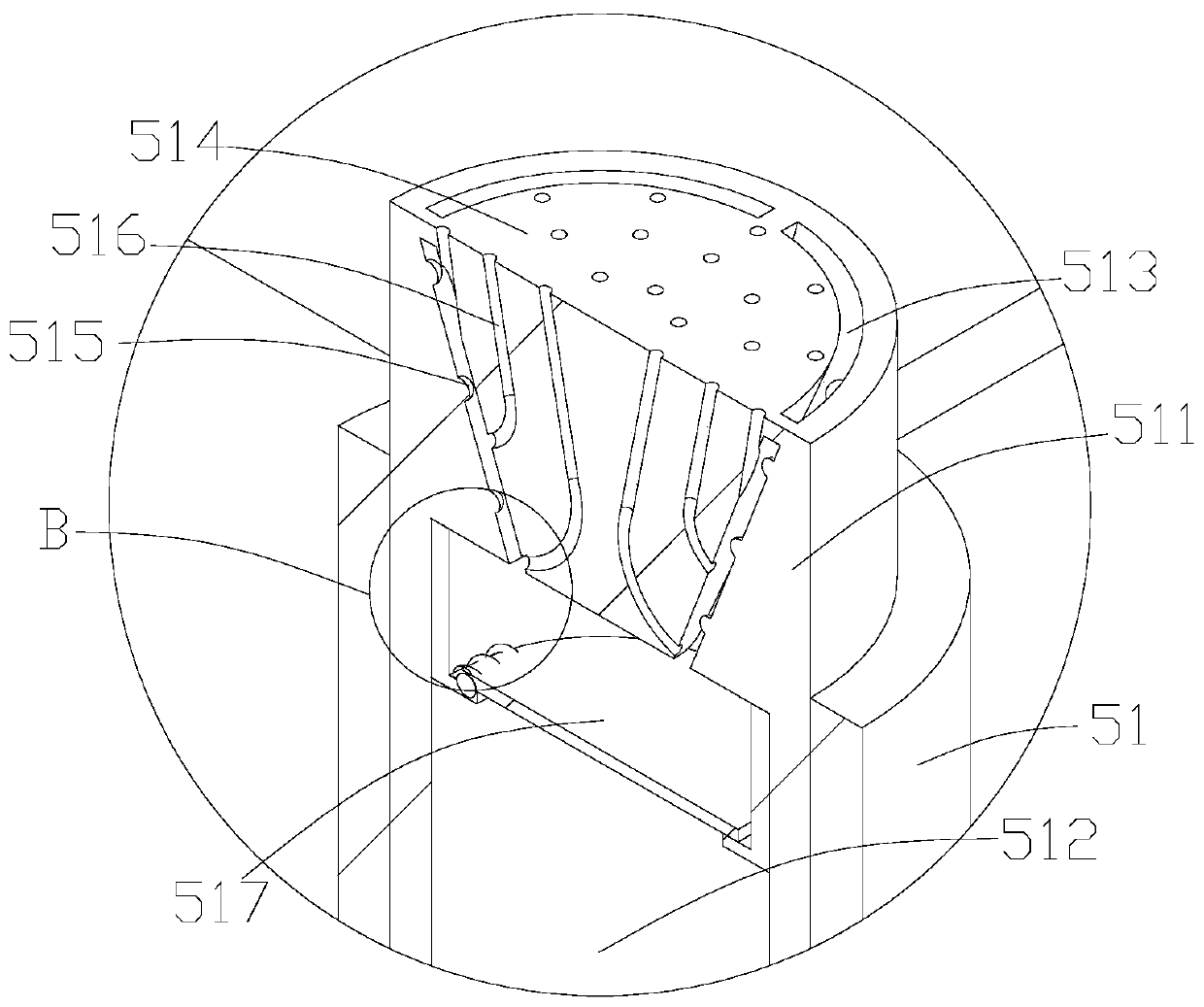

[0028] Such as Figure 1-12As shown, an anti-clogging rubber crushing device for recycling waste tires includes a crushing cylinder 1 for crushing waste tires, a feeding hopper 11 arranged above the crushing cylinder 1, and a crushing knife for crushing waste tires The group 12 and the first driving member 13 used to drive the rotation of the crushing knife group 12 also include a processing chamber 2 for processing crushed rubber particles, a first filter member 3 for filtering rubber exceeding a limited size, and The water spray mechanism for dredging the first filter element 3 and the second filter element 4 for filtering clear water, through the setting of the above structure, after the rubber fragments are broken into particles, they will pass through the first filter element and the second filter element. The effect of screening and water filtration is to facilitate the reliable production of rubber particles, which effectively improves the production stability of rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com