Exchangeable powder collection bin device for additive manufacturing equipment

A technology of additive manufacturing and powder collection bin, applied in the field of additive manufacturing, can solve the problems of threatening the personal safety of staff, long time for disassembly and replacement, waste of manpower and material resources, etc., to improve the working environment, save manpower, The effect of reducing manufacturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

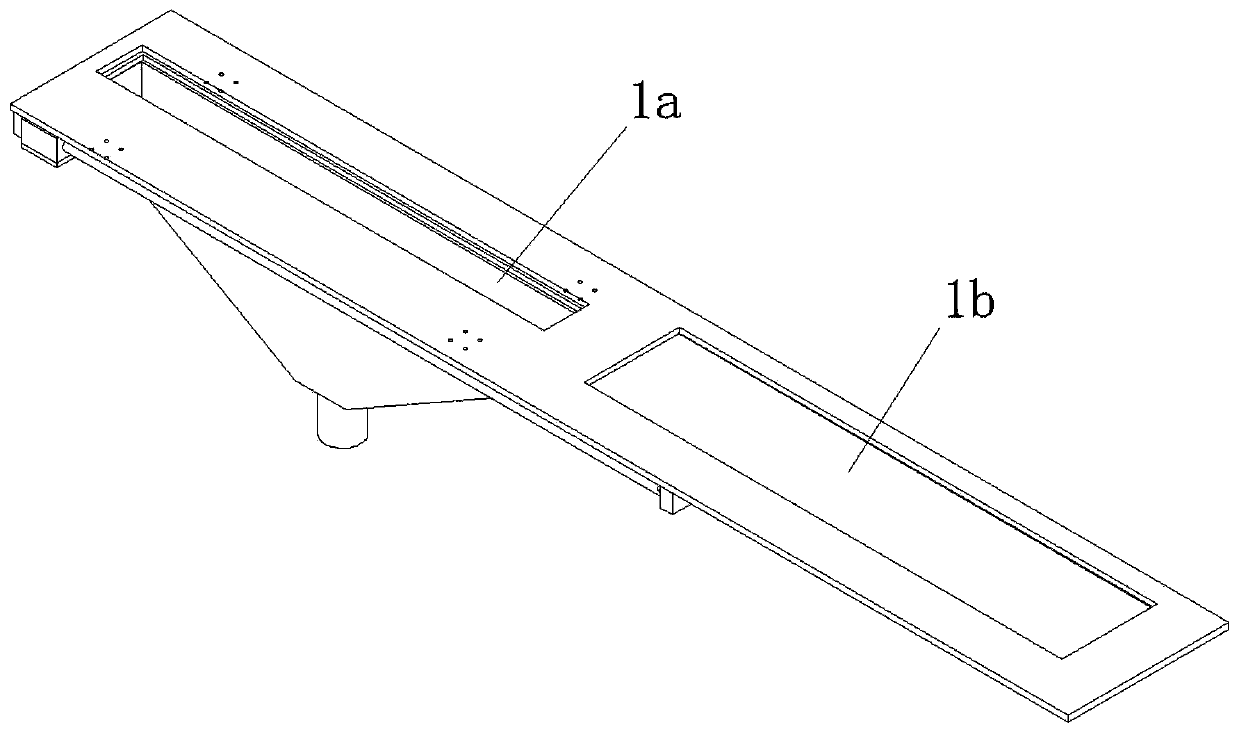

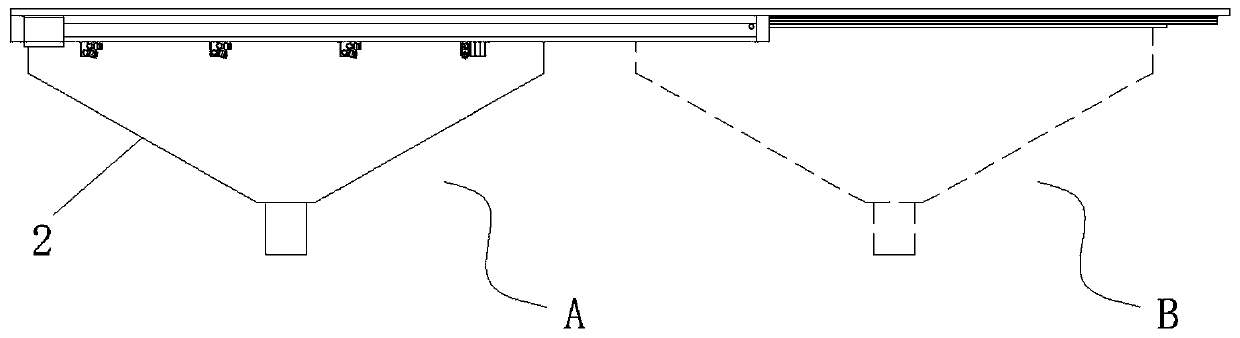

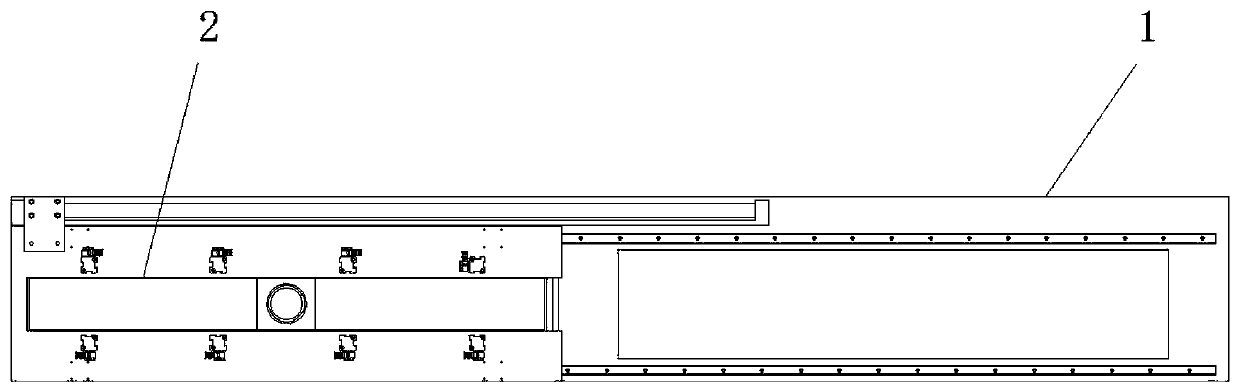

[0026] figure 1 It is a schematic diagram of the three-dimensional structure of the present invention; figure 2 It is a schematic diagram of the side view structure of the present invention; image 3 for figure 2 Looking up at the structural diagram; Figure 4 for figure 2 Schematic diagram of the cross-sectional structure;

[0027] This embodiment provides an exchangeable powder collection bin device for additive manufacturing equipment, including a mounting substrate 1, a powder collecting bin 2 that can be horizontally slidably connected to the bottom of the mounting substrate, and a powder collecting bin that is connected to the mounting substrate and drives the powder collection bin. A drive assembly that slides horizontally. The open end of the powder collecting bin faces the bottom of the mounting base plate. The powder collecting bin slides along the mounting base plate and has at least two stop positions, that is, at least a working position and a dismounting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com