Fast and efficient plastic welding device

A plastic welding and high-efficiency technology, which is applied in the field of fast and efficient plastic welding devices, can solve problems that affect welding quality, uneven welding joints, burrs, burrs, etc., and achieve the effect of ensuring welding effect, ensuring smoothness, and accelerating solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

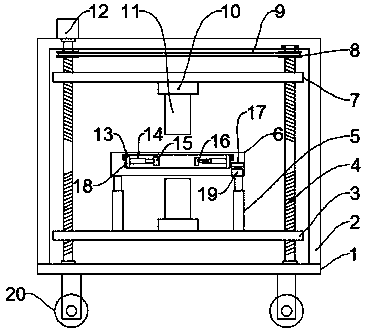

[0024] see Figure 1~3 , in the embodiment of the present invention, a fast and efficient plastic welding device includes a substrate 1, a fixture 10 and a workpiece 11, and rollers 20 are installed on the four corners of the bottom of the substrate 1, and the rollers 20 are self-locking rollers, which facilitate the movement of the device , the upper surface of the substrate 1 is welded and fixed with a gantry 2, both sides of the gantry 2 are installed with two-way screw rods 4 through bearing rotation, and a pulley 8 is installed on the top of the two two-way screw rods 4, and the two pulleys 8 are connected There is a belt 9, and the top of one of the two two-way screw rods 4 is fixedly connected with the output shaft of the first motor 12 through a coupling. The first motor 12 is mounted on the portal frame 2 by screws, and the two two-way screw rods 4 The threaded sections at the upper and lower ends are respectively provided with an upper mounting plate 7 and a lower mo...

Embodiment 2

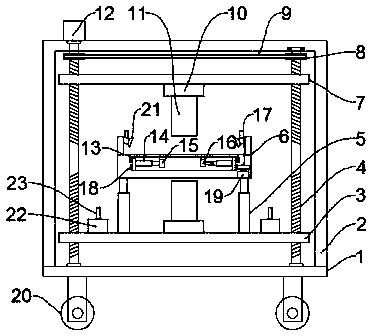

[0026] see image 3 The difference between the embodiment of the present invention and embodiment 1 is that it also includes a cooling device, the cooling device includes a fan 22, an air pipe 23 and a nozzle 21, and the fan 22 is installed on the lower mounting plate 3 by screws. The air outlet of 22 is connected with air pipe 23, and the other end of air pipe 23 is connected with nozzle 21, and nozzle 21 is installed on the top of annular installation shell 6, and nozzle 21 faces the center position of installation ring 13, starts blower fan 22, and blower fan 22 pumps air into air pipe 23 and then Ejected from the nozzle 21, it can air-cool the welding place of the two workpieces 11, accelerate the solidification of the plastic, accelerate the welding speed, and improve work efficiency.

[0027] The working principle of the present invention is: when the present invention is in use, start the first motor 12, the first motor 12 drives two two-way screw mandrels 4 to rotate s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com