Refrigerant hammer arrestor and refrigerant loop incorporating that refrigerant hammer arrestor

A refrigerant circuit, refrigerant technology, applied in the direction of refrigeration and liquefaction, refrigerators, refrigeration components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

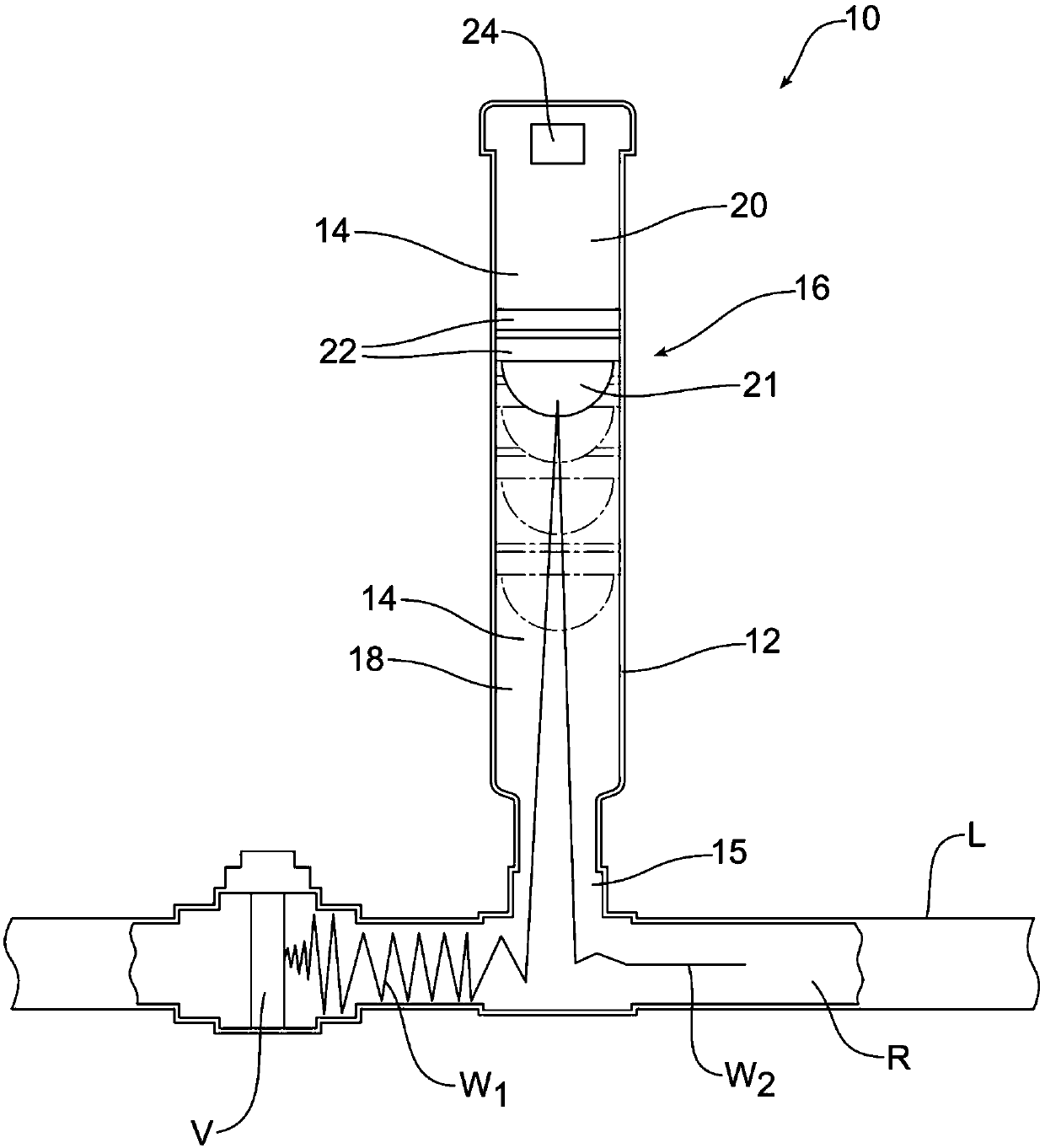

[0027] now refer to figure 1 , which schematically shows a new and improved refrigerant hammer eliminator 10 . The refrigerant hammer eliminator 10 includes a housing 12 . The housing 12 includes an internal compartment 14 . In the embodiment shown, said internal compartment 14 communicates with the refrigerant line L upstream of the shut-off valve V through an open end 15 . Piston 16 is received in housing 12 . The piston 16 divides the inner compartment 14 into a first chamber 18 and a second chamber 20 . In the illustrated embodiment, the piston 16 includes a hemispherical face 21 and two piston rings 22 for providing a smooth sliding action along the inner wall of the housing 12 .

[0028] A damping mechanism, generally indicated at 24 , is provided to slow displacement of the piston 16 within the housing 12 . In the illustrated embodiment, the damping mechanism 24 is arranged in the second chamber 20 .

[0029] The damping mechanism 24 is preferably a variable dampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com