Outer windshield of motor car

A technology for external windshields and trains, which is applied to railway car bodies, railway car body parts, railway transportation, etc. It can solve the problems of poor applicability, poor corrosion resistance of reinforcing ribs, etc., and achieve low cost, improved strength, and convenient mass production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

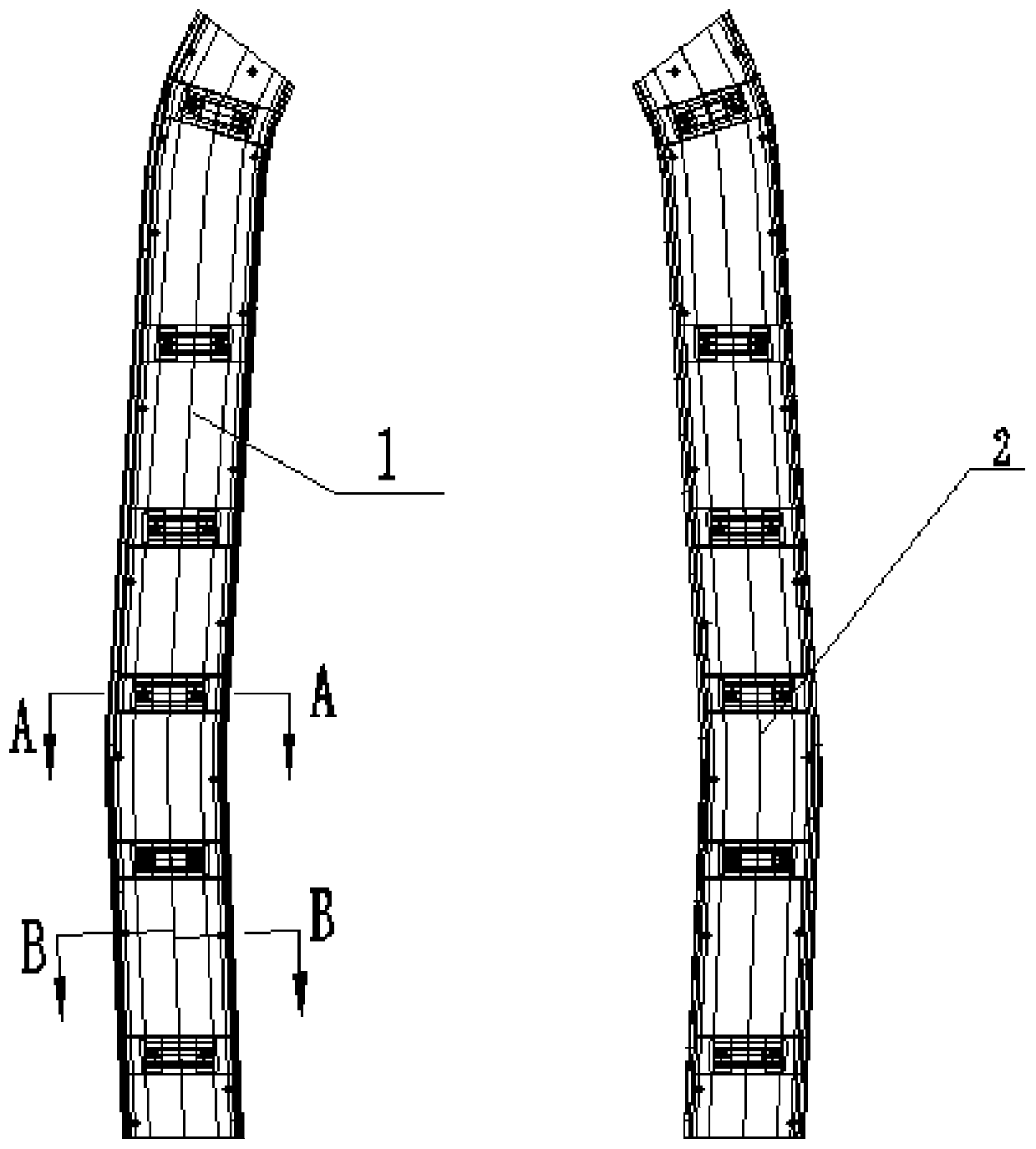

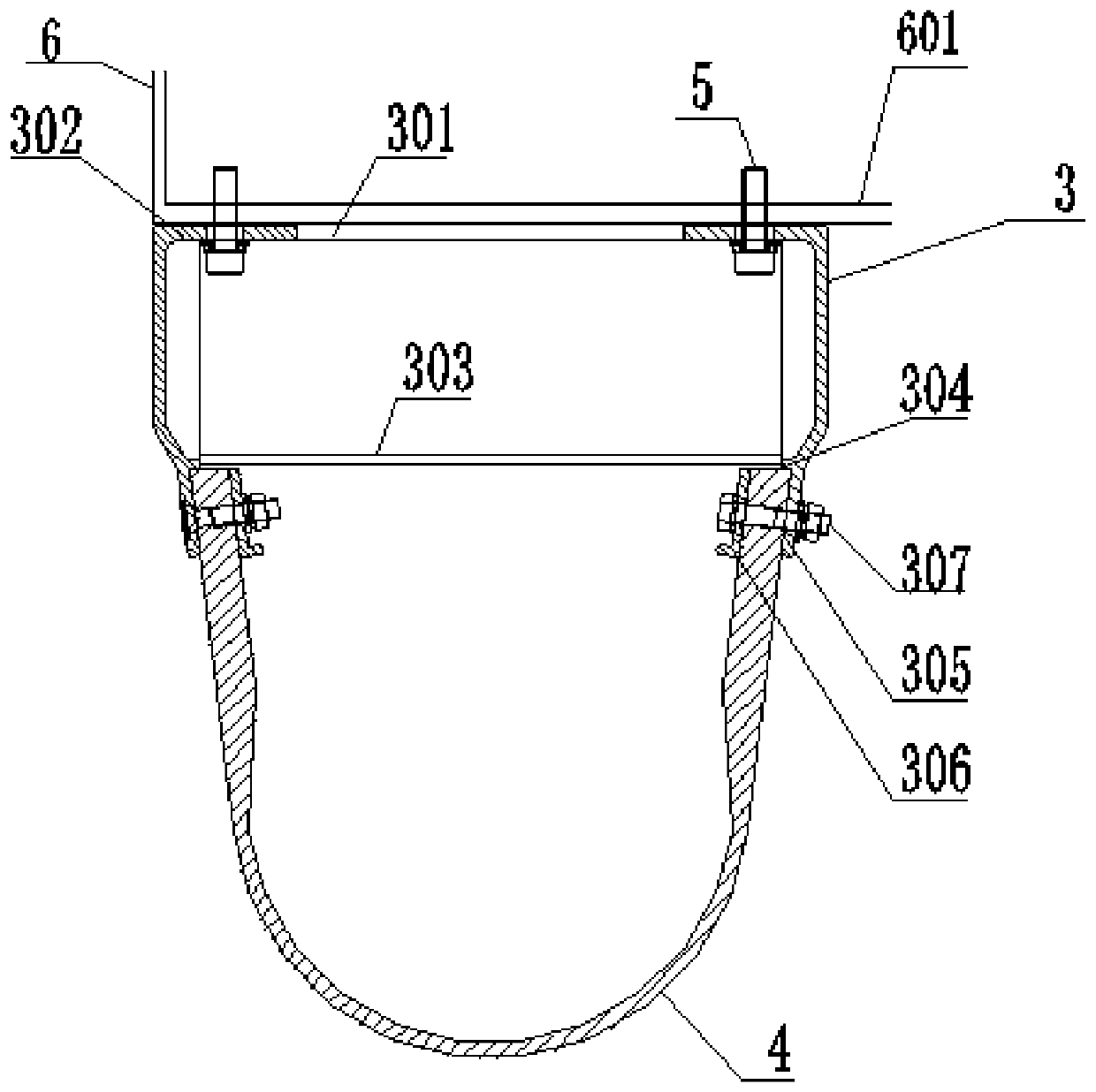

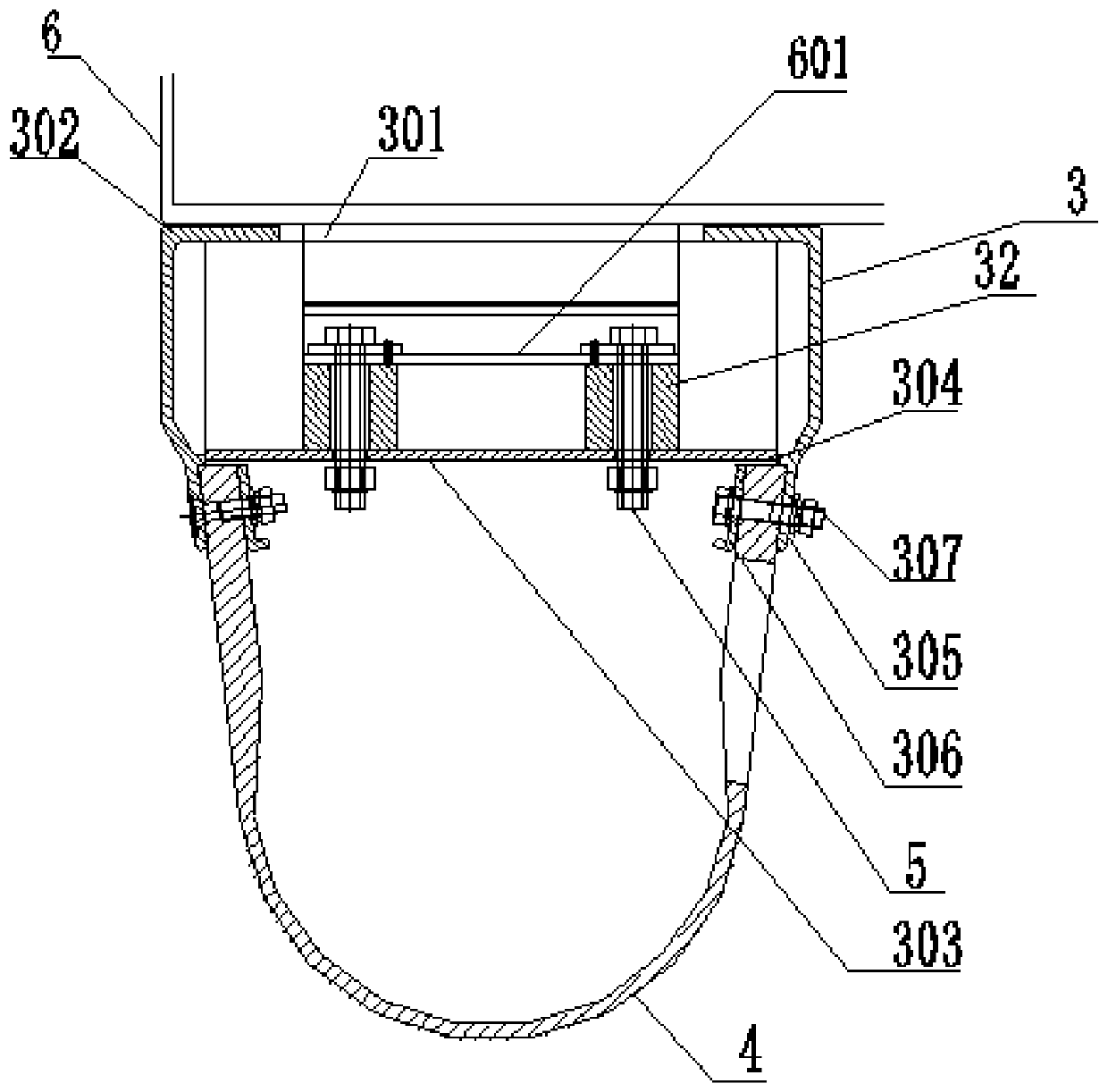

[0027] Such as figure 1 , figure 2 and Figure 5 As shown, an outer windshield of a motor vehicle includes an outer windshield body. The outer windshield body is composed of a symmetrical left side group 1 of the outer windshield and a right side group 2 of the outer windshield. The left side group 1 of the outer windshield includes a mounting seat 3 and a rubber capsule 4 , the reinforcing rib 31 and the aluminum block 32 wrapped inside the reinforcing rib 31, the top of the mounting seat 3 is provided with a hole 301, and one end of the mounting seat 3 is installed on the rubber capsule 4;

[0028] There are two installation structures for the outer windshield body:

[0029] figure 2 As shown, one of the installation structures is that the outer end of the mounting seat 3 of the outer windshield body has a connecting plate 302, and the connecting plate 302 is fixedly connected to the outer windshield connector 601 of the motor car body 6 through the installation fastene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com