Crosspiece structure of R6-level shift mooring chain and shift pressing process

A mooring chain and transom technology, applied in the field of mooring chains, can solve problems affecting the service life of mooring chains, heavy transom weight, shallow indentation depth, etc., to achieve reduced self-weight, uniform indentation depth, and reduced The effect of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose of the invention, technical solutions and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods;

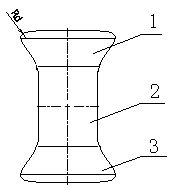

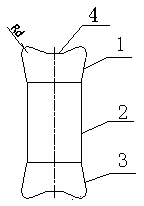

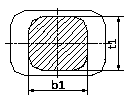

[0015] In the accompanying drawings: a transom structure of an R6 mooring chain, including a transom head 1, a waist 2 and a transom tail 3; it is characterized in that: the transom head 1 and transom tail 3 are set It is pyramid-shaped, and its end face is provided with an arc-shaped pit 4, and the position where the arc-shaped pit 4 intersects with two adjacent sides is provided with a rounded corner Rd; the waist 2 is set as a cuboid, its length is set to b1, and its width It is set as t1; the transition between the head 1 of the rung and the waist 2 and between the waist 2 and the tail 3 of the rung is set as a smooth transition.

[0016] The rounded corner Rd is set to R5-R10mm; the leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com