Rotating tower ring replacing inflating machine

An inflator and turret technology, applied in the direction of conveyor objects, conveyor control devices, vehicle maintenance, etc., can solve the problems of low inflation pressure, time-consuming, labor-intensive, and inability to inflate a variety of tires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in combination with specific embodiments.

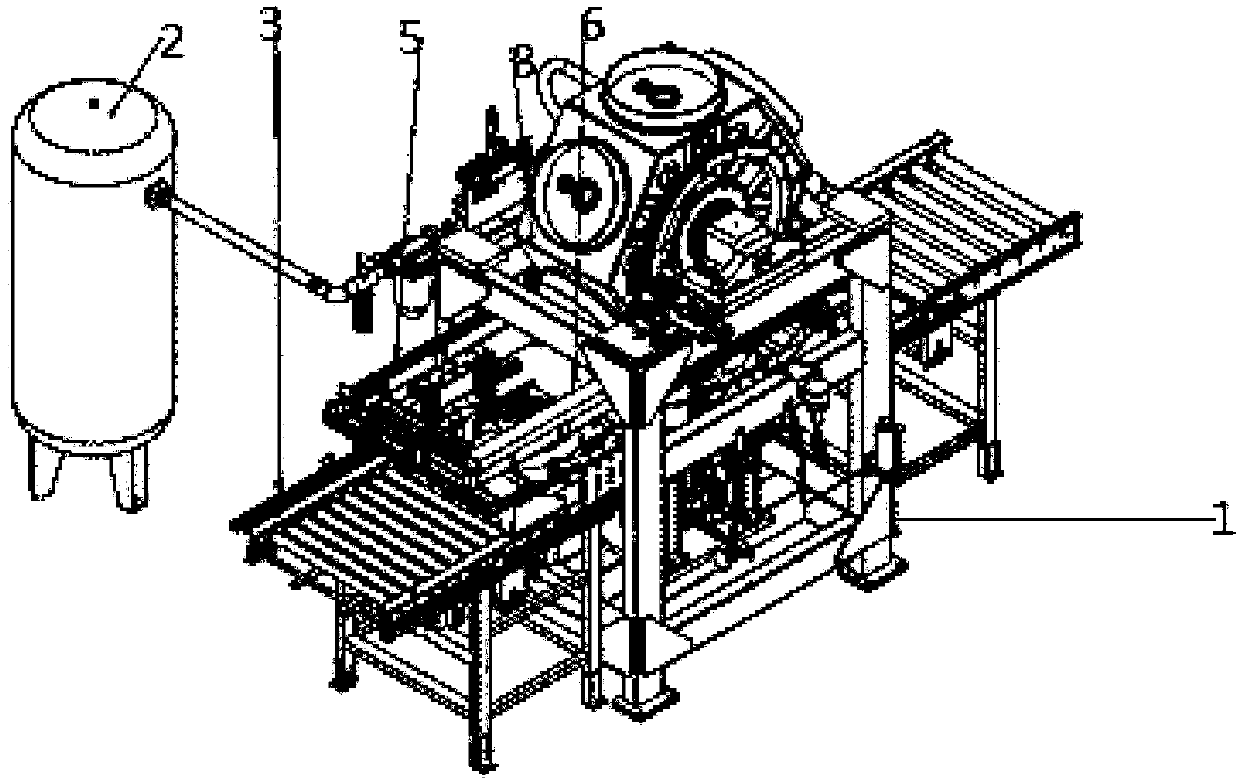

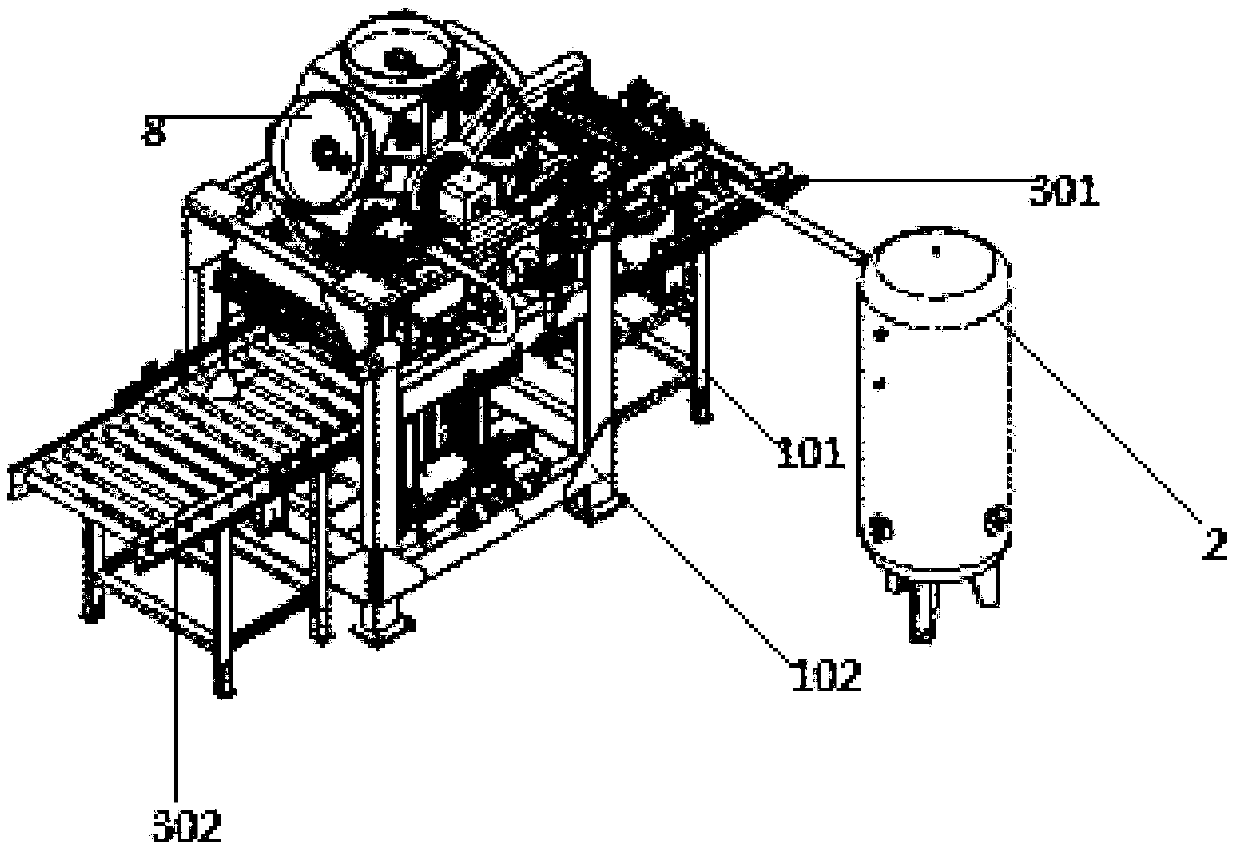

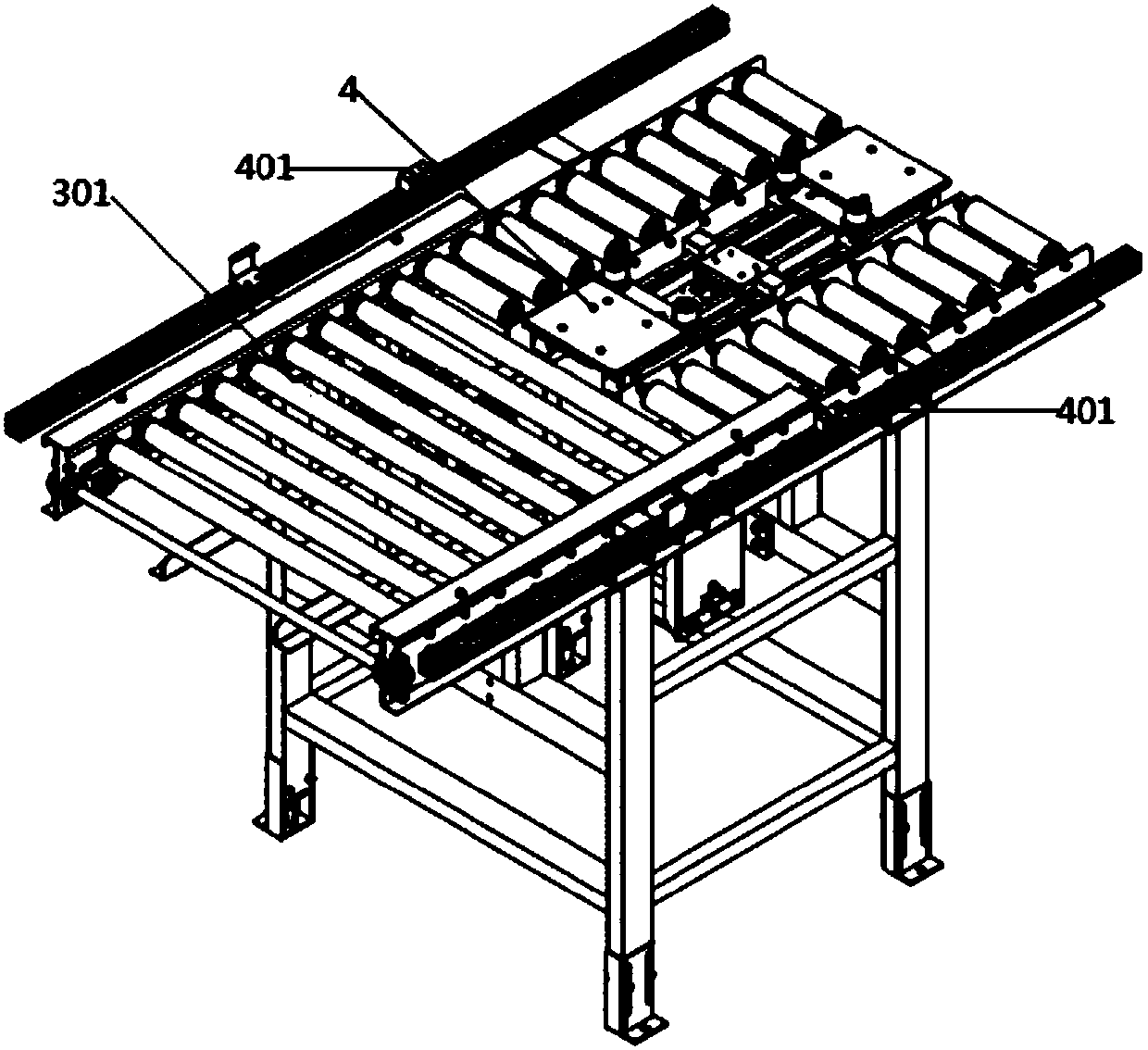

[0028] Such as figure 1 , figure 2 as shown, figure 1 It is a schematic structural diagram of the turret ring-changing inflator of the present application, figure 2 It is another structural schematic diagram of the turret ring-changing inflator of the present application. refer to figure 1 , figure 2 As shown, the present application discloses a turret ring-changing inflator with a maximum inflation pressure of 4.2 Bar, which includes a base 1, an air source 2, a conveying mechanism 3, a centering mechanism 4, a transplanting mechanism 5, and a gas-liquid integration Lifting mechanism 6, upper centering detection mechanism 7, turret ring changing mechanism 8 and a PLC control system, wherein, the tire information is preset in the PLC control system, and the PLC control system is connected with the conveying mechanism 3, the centering mechanism 4, the shifting mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com