A kind of multinuclear microsphere selective water blocking agent and preparation method thereof

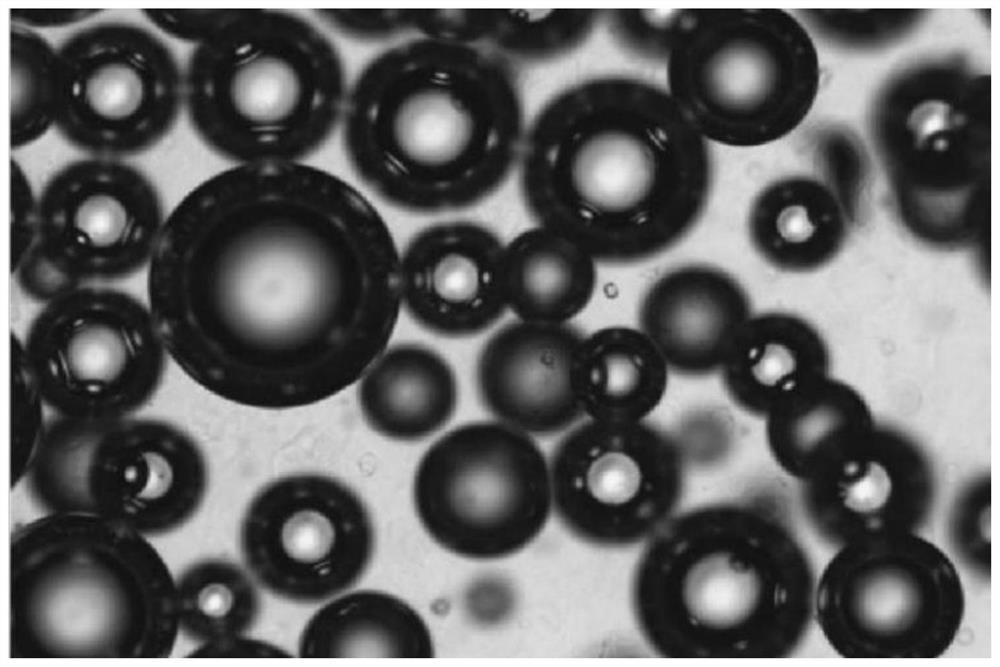

A water blocking agent and selective technology, applied in the field of multi-core microsphere selective water blocking agent and its preparation, can solve the problems of poor plugging effect in high permeability formations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

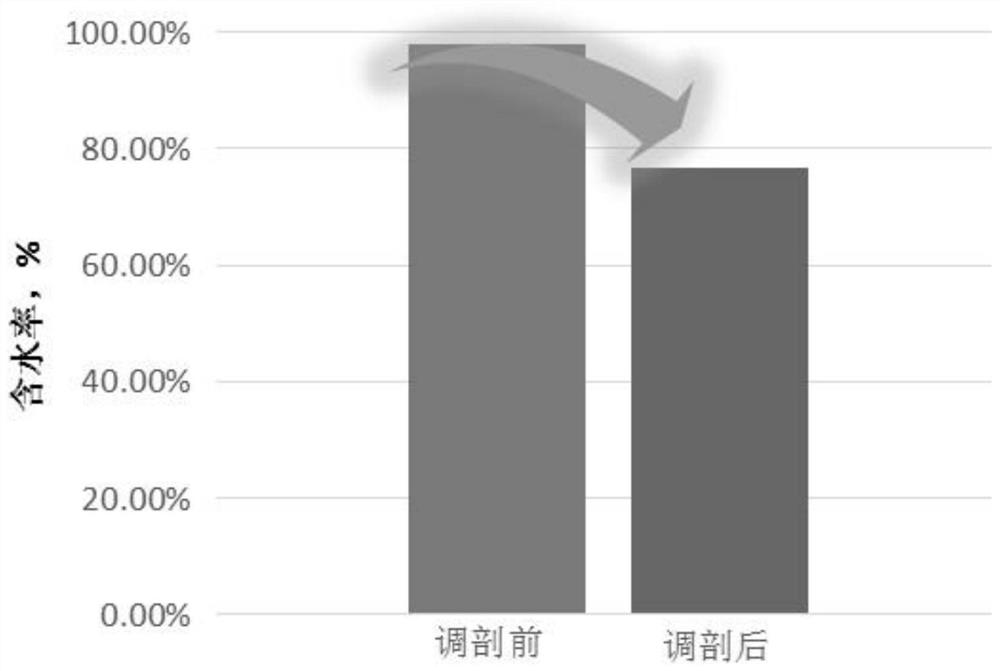

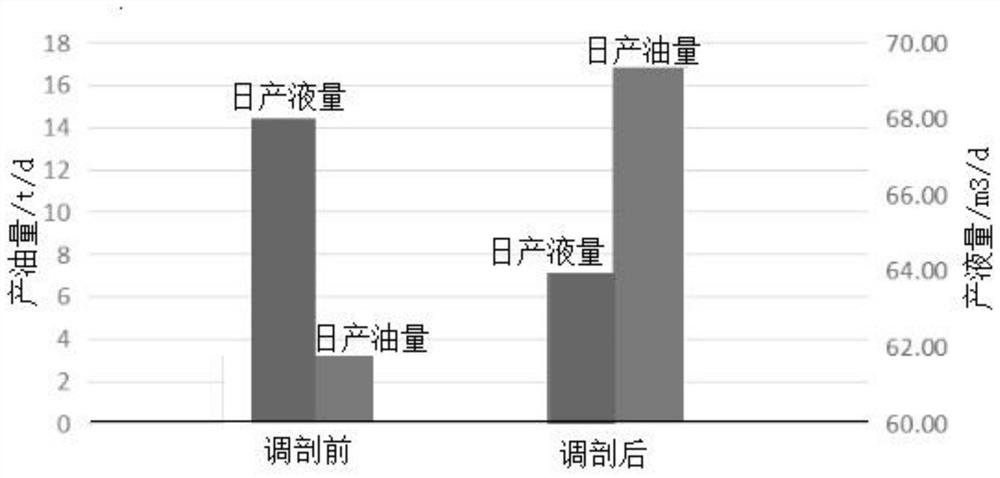

Examples

Embodiment 1

[0020] In a 500 ml reaction flask, replace the air with nitrogen, then add 60 grams of L-lactide, 40 grams of aspartic acid, 30 grams of 2-ethyl-2-oxazoline, and 70 grams of dimethyl carbonate into the reaction flask and heat up to 120°C, start the stirrer, then add 0.08 g of stannous valerate catalyst and 0.5 g of potassium hydroxide, and gradually raise the temperature of the reaction liquid system to 150°C for constant temperature reaction for 8 hours, and cool the obtained product after the reaction is completed After cooling, a solid phase product is obtained, and the product is crushed by a pulverizer to obtain a powder with a particle size of 100-200 mesh, which is the water blocking agent.

[0021] The water shutoff agent synthesized by the method is suitable for water shutoff construction of oil and gas wells below 90°C.

Embodiment 2

[0023] In a 500ml reaction flask, replace the air with nitrogen, then add 80 grams of L-lactide, 50 grams of aspartic acid, 40 grams of 2-ethyl-2-oxazoline, and 30 grams of dimethyl carbonate into the reaction flask and heat up to 120°C, start the stirrer, then add 0.1 g of stannous valerate catalyst and 0.6 g of potassium hydroxide, and gradually raise the temperature of the reaction liquid system to 150°C for constant temperature reaction for 8 hours, and cool the obtained product after the reaction is completed. After cooling, a solid phase product is obtained, and the product is crushed by a pulverizer to obtain a powder with a particle size of 100-200 mesh, which is the water blocking agent.

[0024] The water shutoff agent synthesized by the method is suitable for water shutoff construction of oil and gas wells at 90-150°C.

Embodiment 3

[0026] In a 500ml reaction flask, replace the air with nitrogen, then add 80 grams of L-lactide, 50 grams of aspartic acid, 40 grams of 2-ethyl-2-oxazoline, and 30 grams of dimethyl carbonate into the reaction flask and heat up to 130°C, start the stirrer, then add 0.1 gram of stannous valerate catalyst and 0.6 gram of potassium hydroxide, and gradually heat up the reaction liquid system to 140°C for constant temperature reaction for 10 hours, and cool the obtained product after the reaction is completed. After cooling, a solid phase product is obtained, and the product is crushed by a pulverizer to obtain particles with a particle size of 1-8 mm, which is the water blocking agent.

[0027] The water shutoff agent synthesized by the method is suitable for water shutoff construction of oil and gas wells at 90-150°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com