Superfine fiber non-woven fabric sizing machine

A technology of ultra-fine fiber and non-woven fabrics, applied in the field of textile manufacturing, can solve problems such as poor working environment, waste of raw materials, dripping of slurry, etc., and achieve the effect of reducing waste of slurry, protecting the working environment, and not easy to disengage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

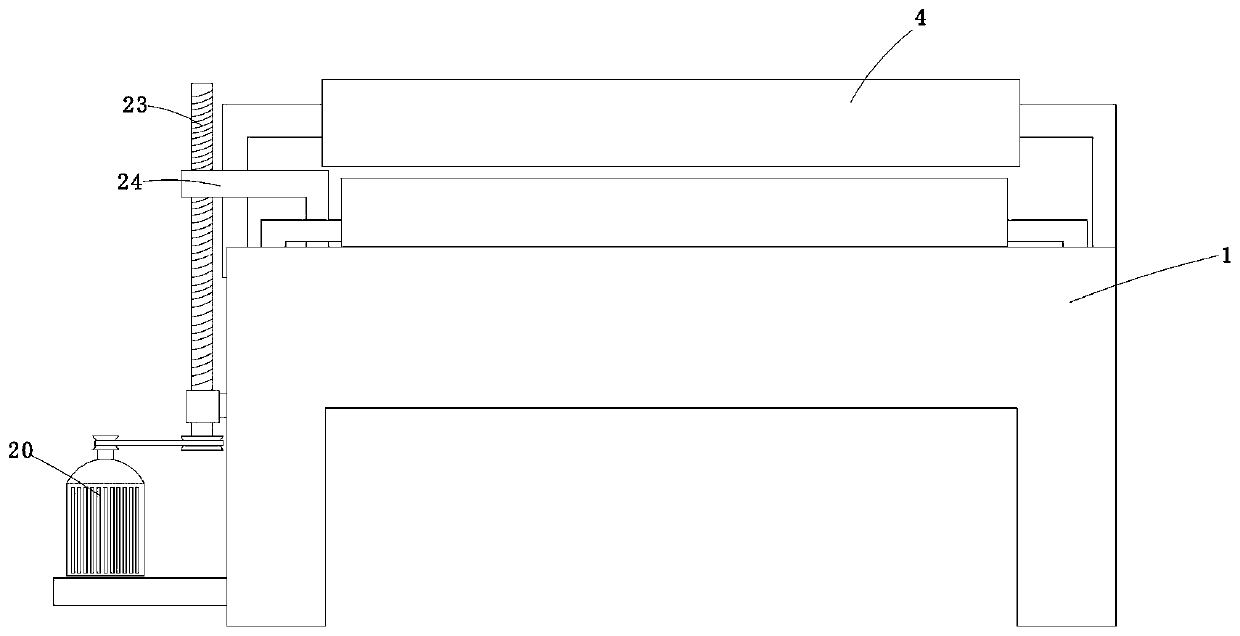

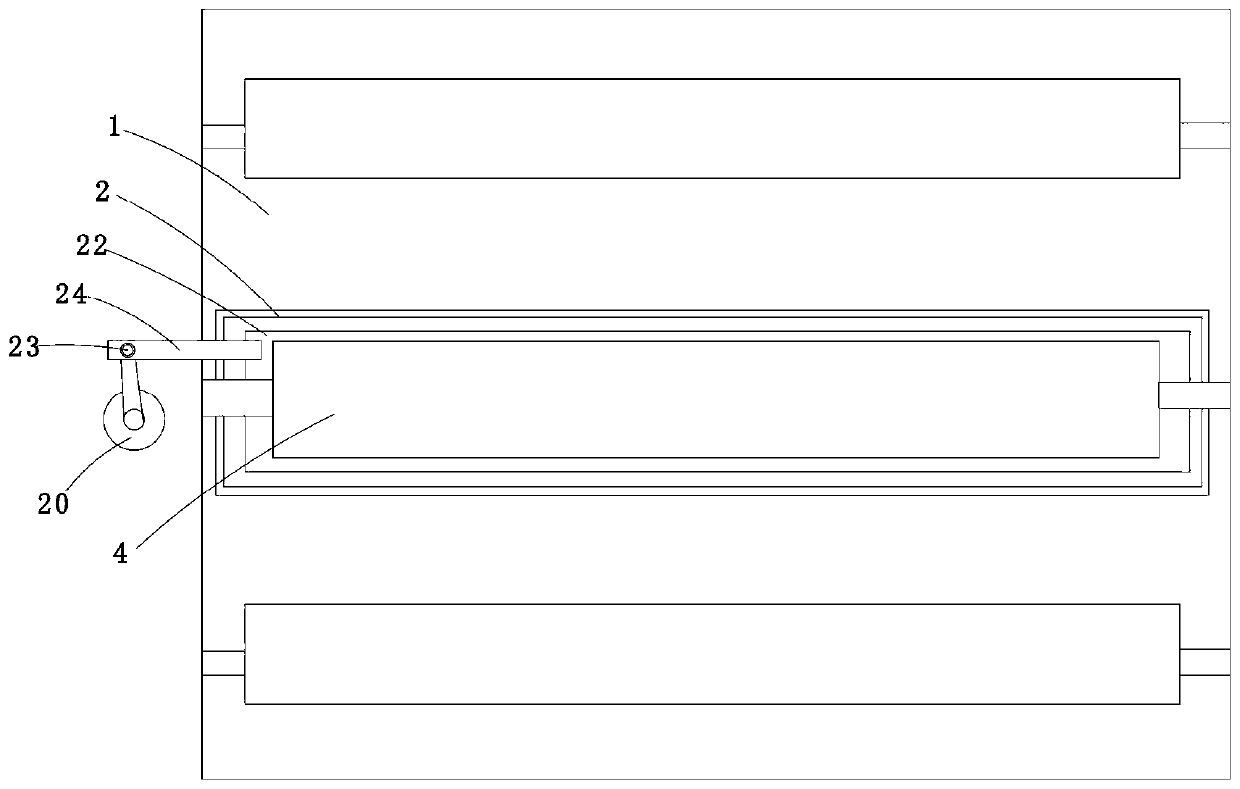

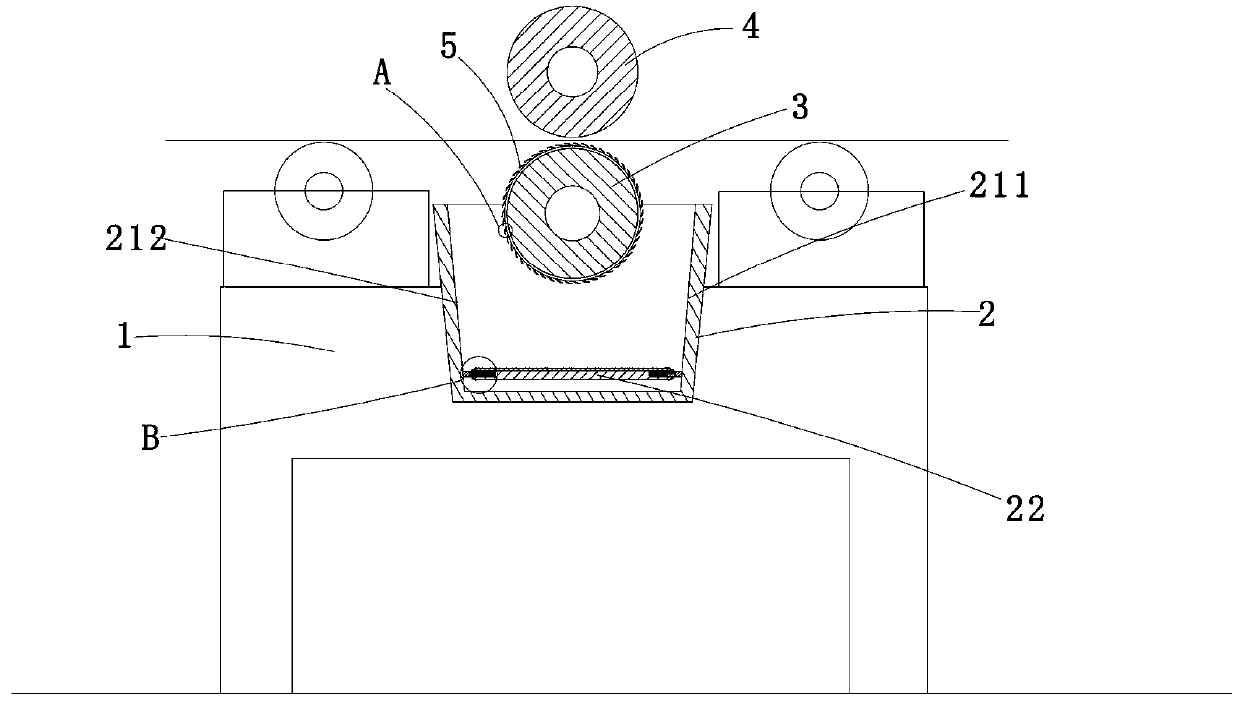

Embodiment 1

[0028] Such as Figure 1-10 As shown, the present invention discloses a superfine fiber non-woven fabric sizing machine, the roll body machine includes a frame 1, a dip tank 2, a first roll body 3 and a second roll body 4, wherein the frame 1 It is a metal frame, and the dipping tank 2, the first roller body 3 and the second roller body 4 are all arranged on the frame, the second and first roller bodies are metal rollers, and the first roller body is a metal roller. The second roller body 4 is arranged above the first roller body 3; a drive motor 7 is arranged on the frame 1, and the drive motor 7 drives the second roller body 4 to rotate clockwise and drives the first roller body 3 Rotate counterclockwise; the first roller body 3 is at least partly arranged in the dipping tank 2, so during the single-side sizing process of the superfine fiber non-woven fabric, the superfine fiber non-woven fabric is arranged on the second, Between the first roller bodies, the first roller bo...

Embodiment 2

[0038] Such as Figure 11-12 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment is additionally equipped with a slurry recovery component 7 on the frame, specifically: the slurry recovery component 7 includes a recovery tank 71 and a material guide pipe 72, so The recovery tank 71 is a groove arranged on the frame 1, and the bottom of the recovery tank 71 is inclined from top to bottom; the guide pipe 72 is a metal pipe inclined from top to bottom. The upper part of the guide tube 72 communicates with the recovery tank 71, and the lower part of the guide tube 72 communicates with the dipping tank 2, so the slurry falling into the recovery tank 71 passes through the guide tube 72 into the dip tank 2.

[0039] Further, the slurry recovery part 7 also includes a filter element 73, which is a metal filter plate, and a plurality of filter holes 730 are arranged on the filter element 73, and the inner wall of the filter hole 730 It is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com