Assembly type steel hanging box structure

A prefabricated, steel hanging box technology, applied in infrastructure engineering, caissons, buildings, etc., can solve problems such as poor integrity, defects in the rigidity of the bottom plate, and difficulties in assembly and dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

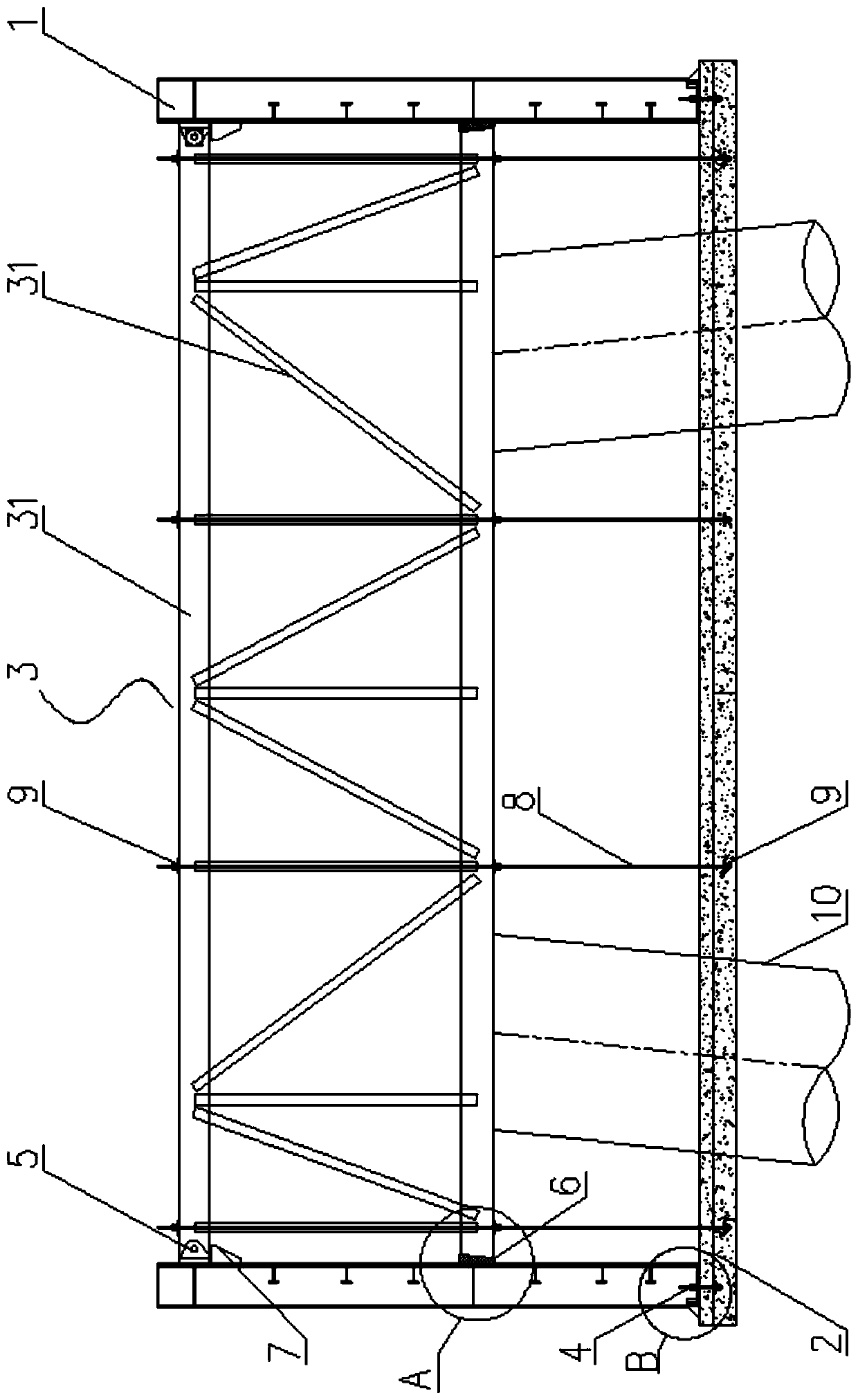

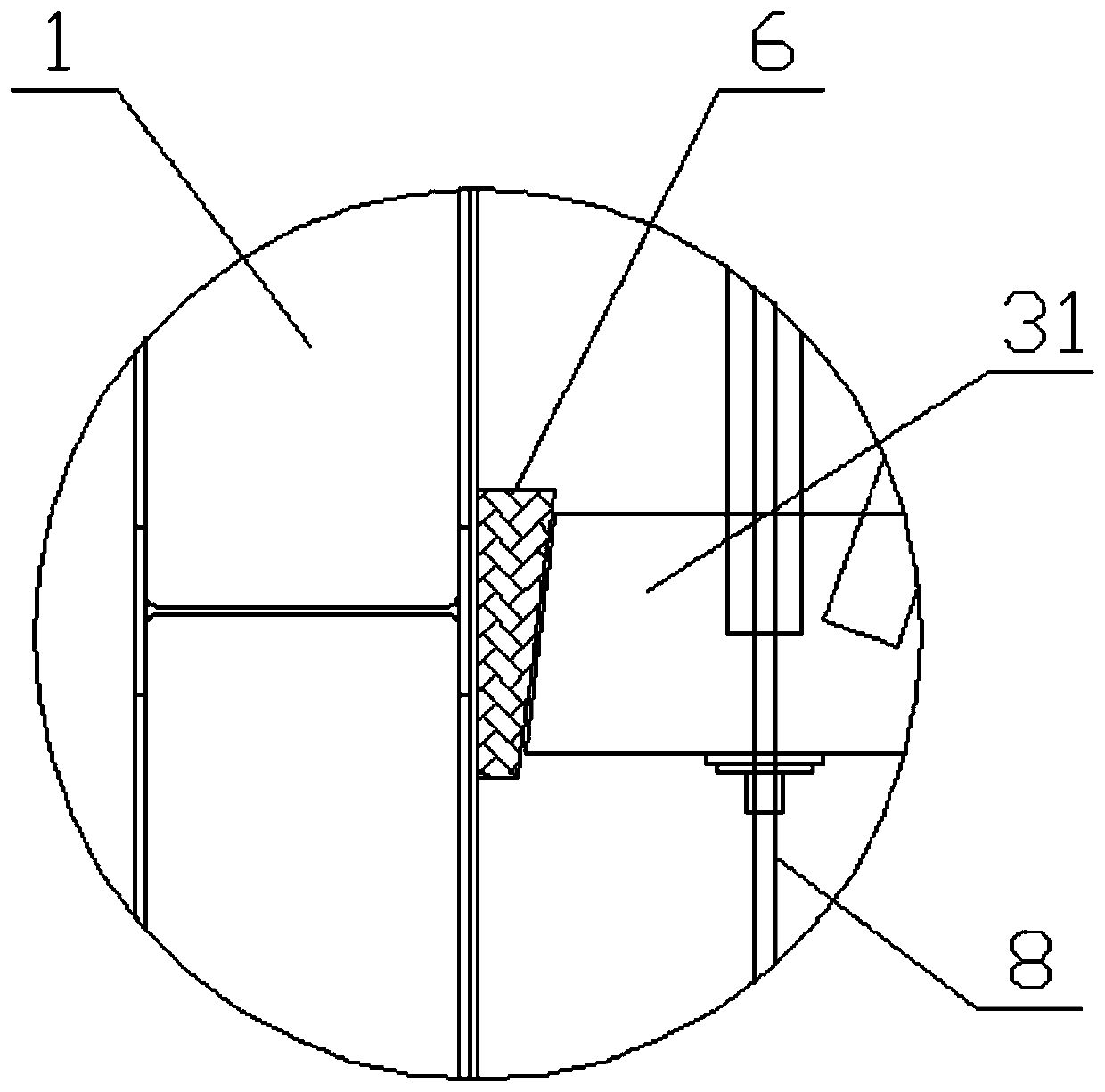

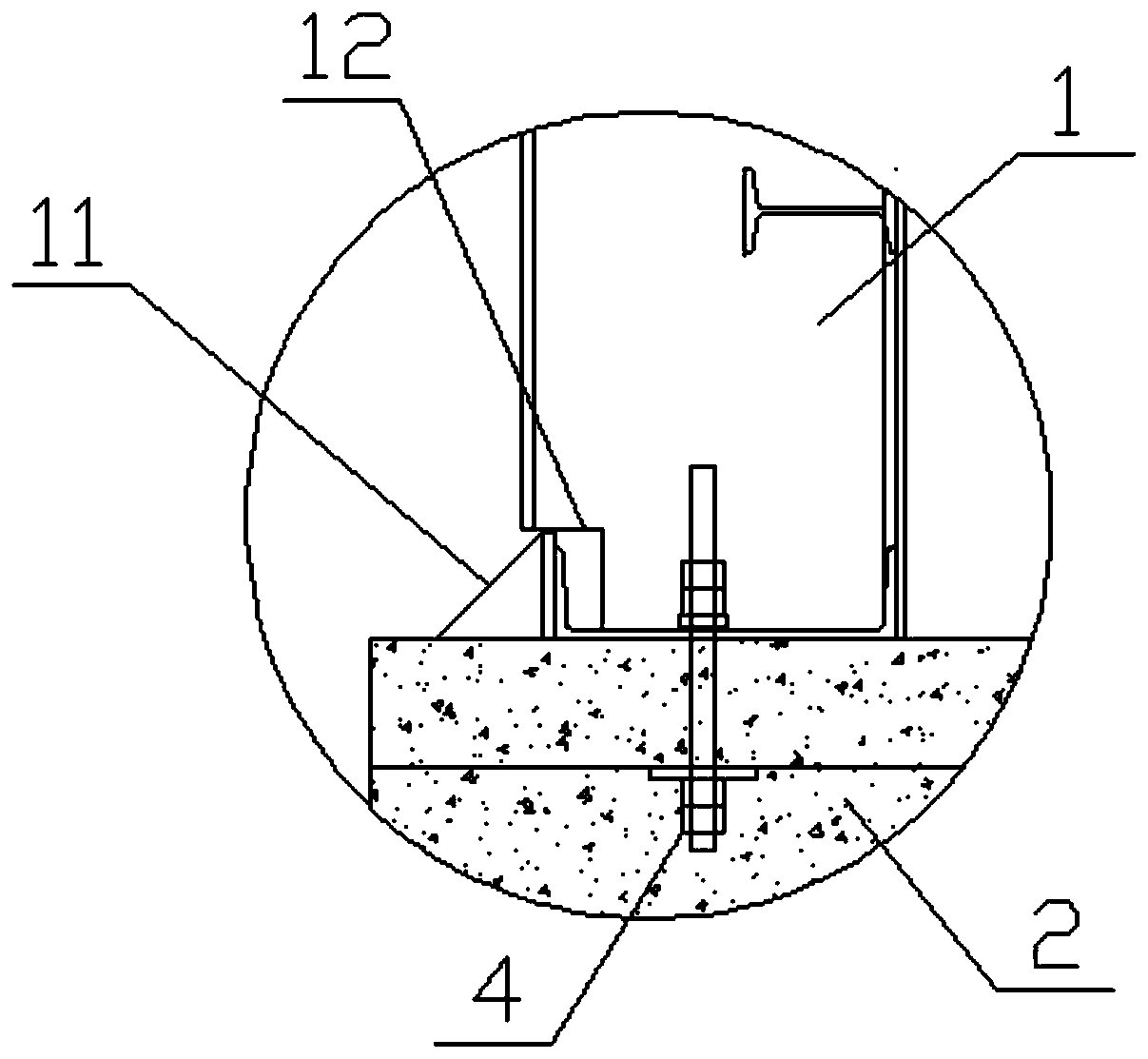

[0023] Such as Figure 1 to Figure 3 As shown, an assembled steel suspension box structure includes a base plate 2, a wall body 1 and an assembled truss structure 3, the base plate 2 is provided with several anchor bolts 4 or bolts, and the wall body 1 passes through the anchor bolts 4 or The bolts are welded and fixed to the bottom plate 2, and the inner wall of the wall body 1 is provided with several hinged seats 5 and wedge-shaped pads 6 and the hinged seats 5 and wedge-shaped pads 6 are respectively in two planes, and the hinged seats 5 are located on the wedge-shaped pads. Above the block 6, the wedge-shaped spacer 6 plays the role of supporting and limiting the assembled truss structure 3. The upper end side of the assembled truss structure 3 is connected with the hinge seat 5, and the lower end side of the assembled truss structure 3 is connected by a wedge-shaped Spacers 6 limit the position, and a number of suspenders 8 are connected between the bottom surface of the...

Embodiment 2

[0030] An assembled steel suspension box structure, comprising a bottom plate 2, a wall body 1 and an assembled truss structure 3, the bottom plate 2 is provided with several anchor bolts 4 or bolts, and the wall body 1 is connected to the bottom plate through the anchor bolts 4 or bolts 2 Welding and fixing, the inner wall of the wall body 1 is provided with a number of hinged seats 5 and wedge-shaped pads 6 and the hinged seats 5 and wedge-shaped pads 6 are respectively in two planes, and the hinged seats 5 are located on the sides of the wedge-shaped pads 6 Above, the wedge-shaped spacer 6 plays the role of supporting and limiting the assembled truss structure 3. The upper end side of the assembled truss structure 3 is connected with the hinge seat 5, and the lower end side of the assembled truss structure 3 passes through the wedge-shaped spacer 6. Position limit, the bottom surface of the assembled truss structure 3 and the bottom plate 2 are also connected with a number o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com