Plasma display board

A plasma and display panel technology, applied in alternating current plasma display panels, static indicators, gas discharge electrodes, etc., which can solve the problems of low contrast and brightness development level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The content of the present invention will be described in detail below with reference to the accompanying drawings.

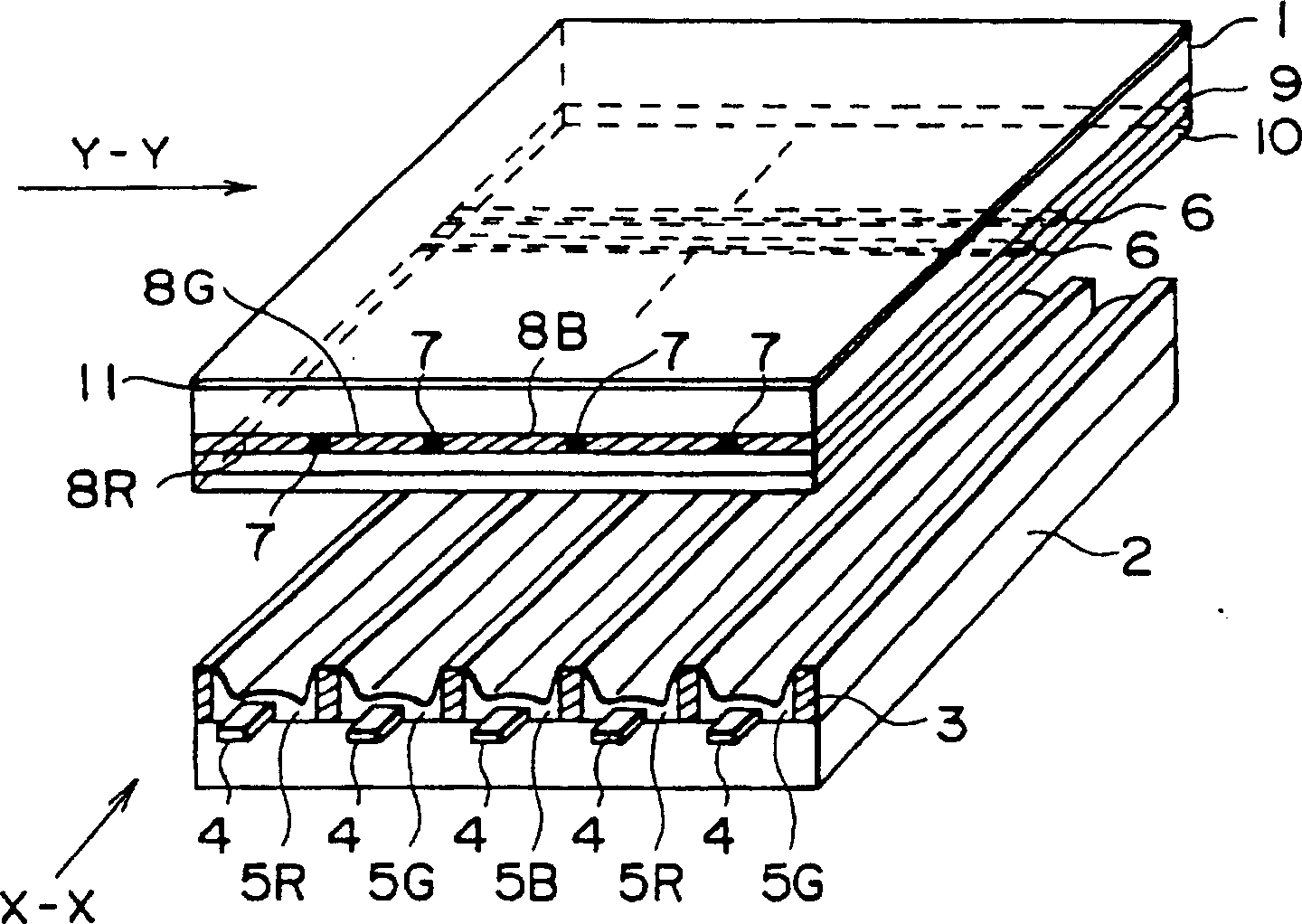

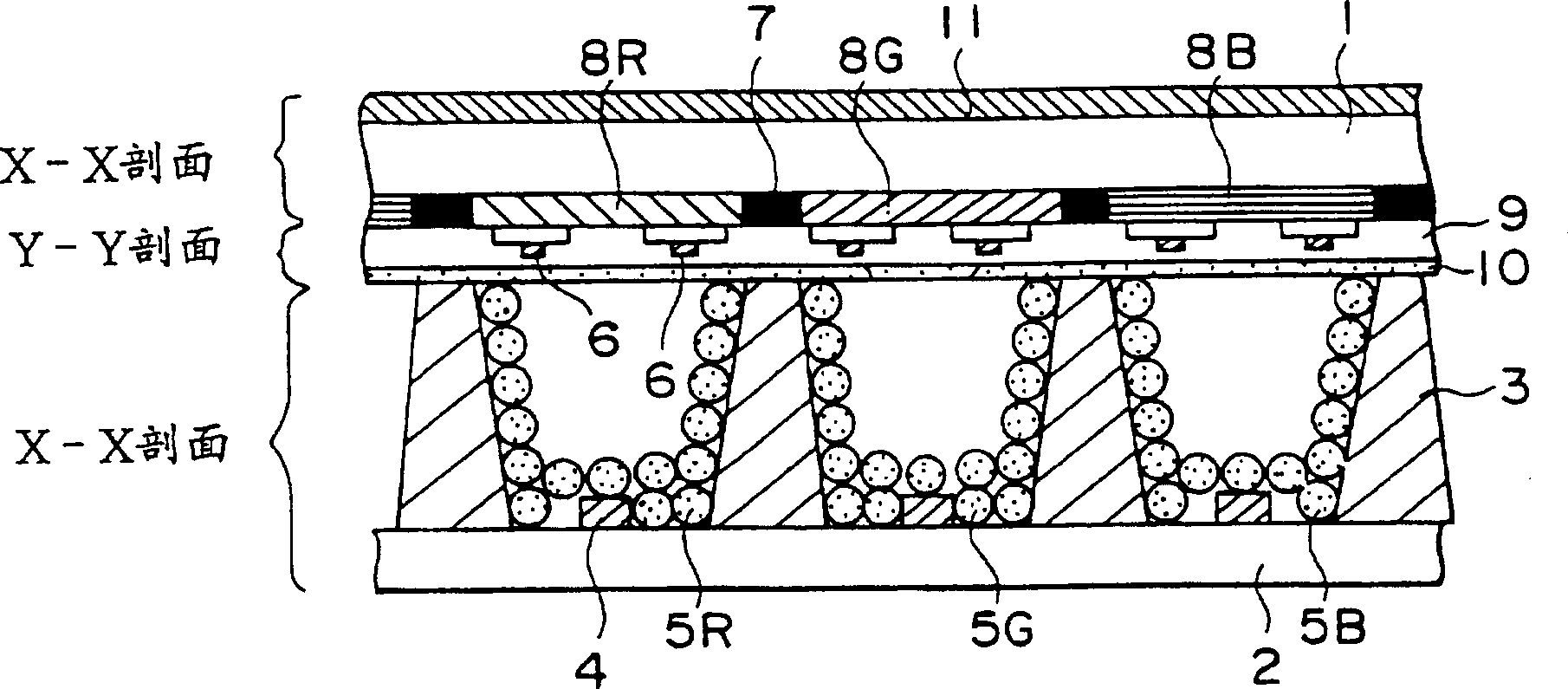

[0026] figure 1 is a perspective view of the entire human structure of an embodiment of the plasma display panel of the present invention, figure 2 yes figure 1 An enlarged view of a partial cutaway of a plasma display panel. Number 1 indicates the front glass substrate (front plate), 2 is the rear glass substrate (rear plate), 3 is the barrier rib, 4 is the address electrode, 5R, 5G and 5B are fluorescent substances, 6 is the support electrode, and 7 is the black matrix , 8R, 8G, 8B are color filters, 9 is an insulating layer, 10 is a protective layer, and 11 is a band selection filter.

[0027] from figure 1 with figure 2 It can be seen from the embodiment that the plasma display panel has such a structure: the front glass substrate 1 and the rear glass substrate 2 are arranged facing each other, and barrier ribs 3 are placed between the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com