A method for calculating the compressive bearing capacity of a double-angle steel cross-shaped combined section component

A technology that combines cross-sections and calculation methods, applied in calculation, electrical digital data processing, instruments, etc., can solve problems such as unreasonable regulations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

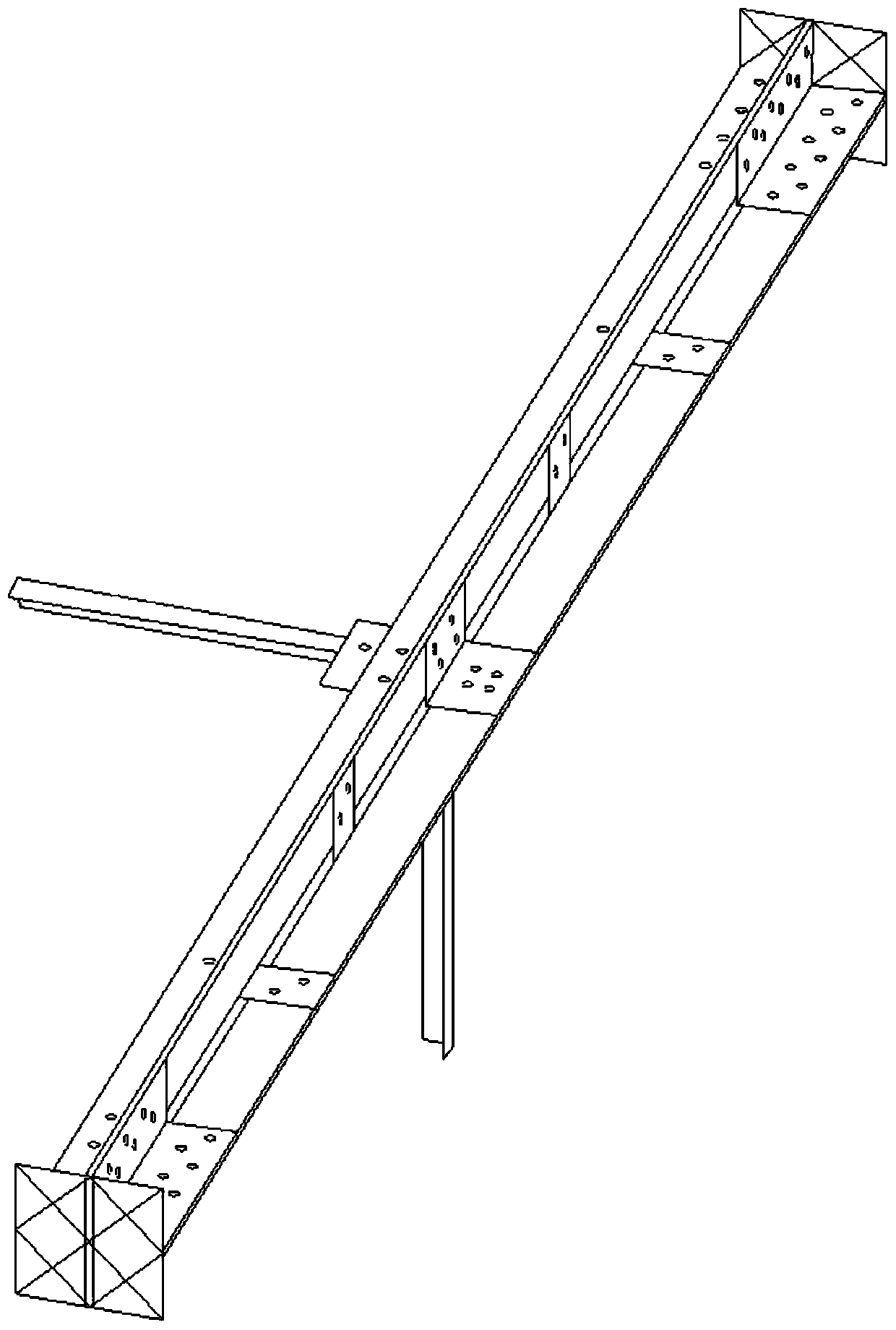

[0060] In this embodiment, the software ANSYS is used to establish the finite element model of the double angle steel cross composite section member, such as figure 2 As shown, the finite element analysis is carried out on the finite element model. The joint model is simulated by the shell element SHELL181. The shell element SHELL181 can be better adapted to problems such as linearity, large rotation, and nonlinear large deformation.

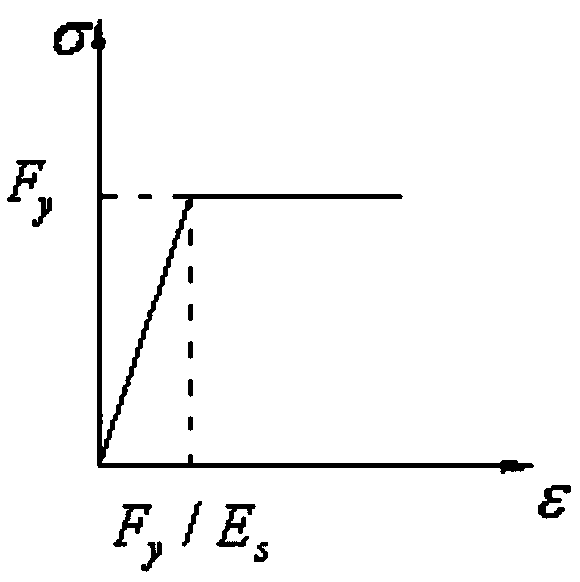

[0061] In the embodiment, the component material is Q420 high-strength angle steel, the yield strength is taken as 420MPa, the elastic modulus of the material is taken as E=2.06e5MPa, and the Poisson's ratio is taken as 0.3. The stress-strain relationship of component materials adopts an ideal elastoplastic material model, such as figure 1 shown.

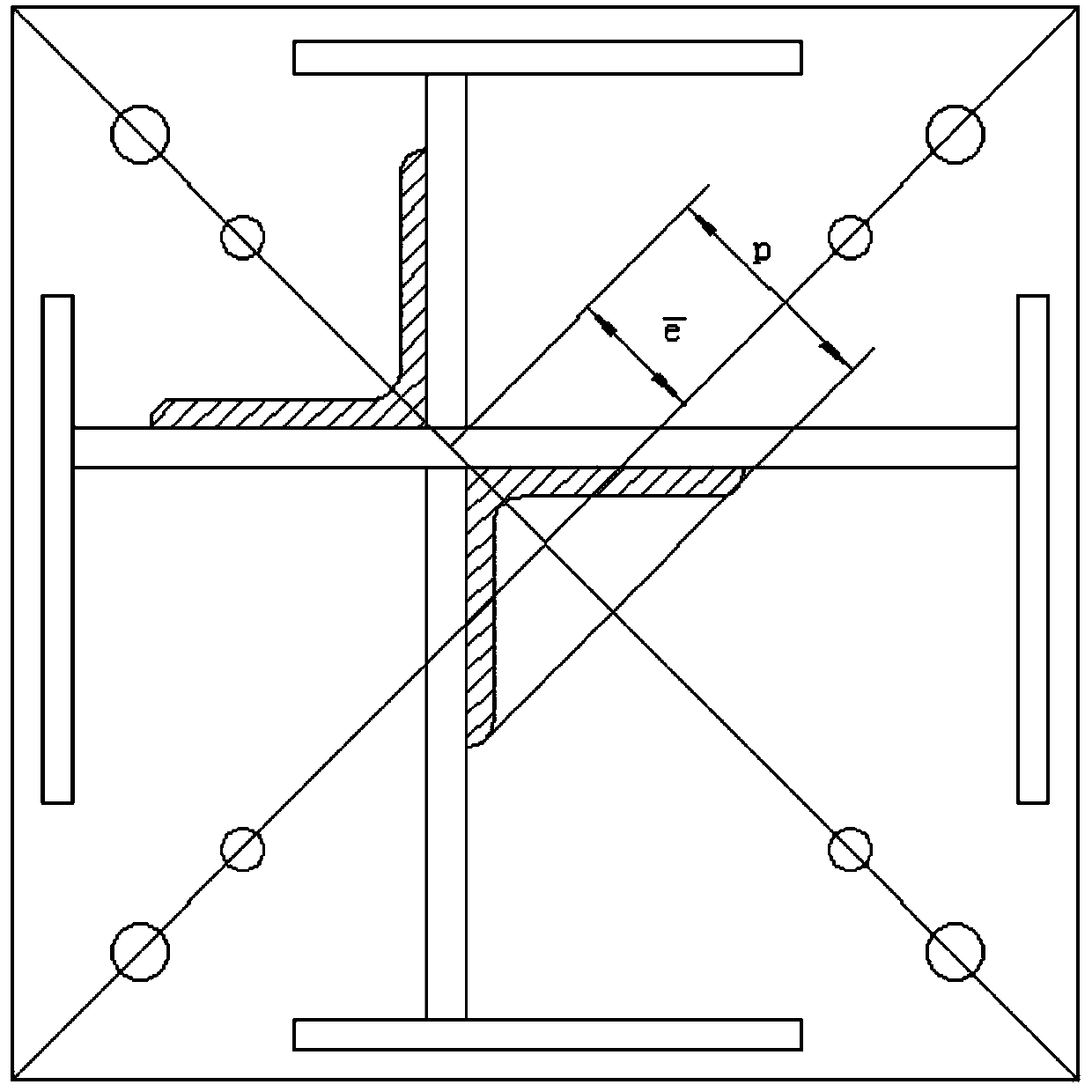

[0062] In the process of finite element analysis, the eccentric load acts along the weak or strong axis of the double-angle steel cross section (the strong axis refers to the axis with a larger sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com