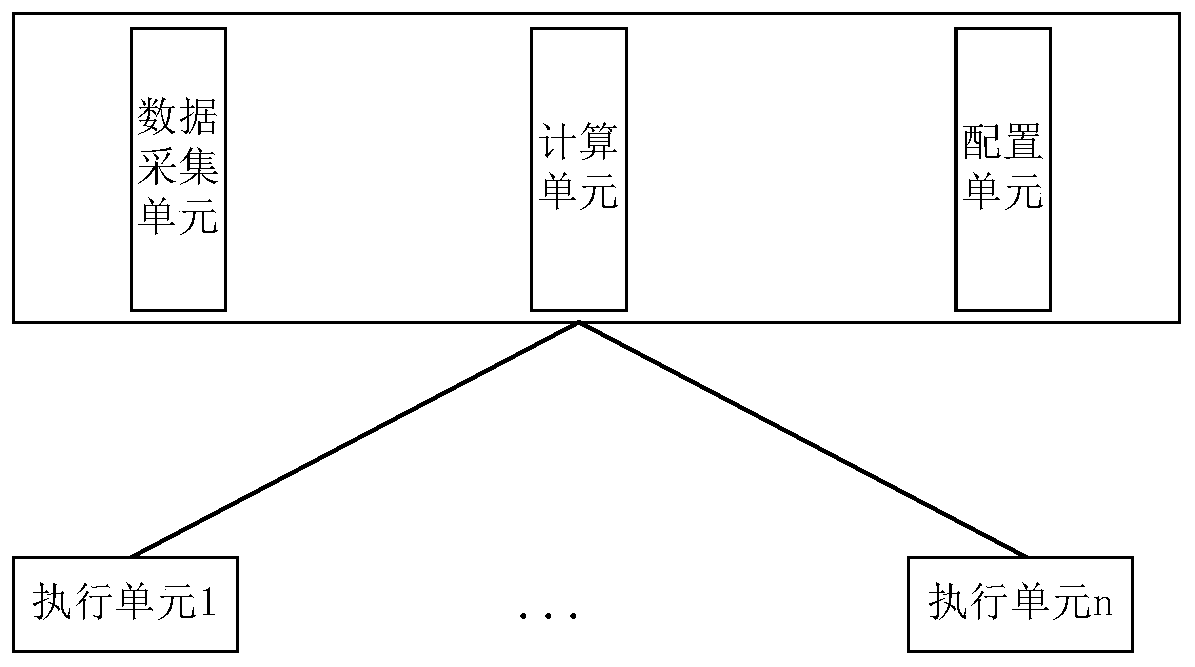

Equipment maintenance personnel scheduling system

A technology for personnel scheduling and equipment maintenance, applied in the field of personnel scheduling, it can solve the problems of rationality of personnel allocation and reasonableness of work, and achieve the effect of reducing maintenance costs and precise scheduling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0027] Specific implementation method: the basic data and data sources of the system: the specific location of each factory station is located by GPS to obtain the basic data of the factory station; the current real-time weather data is obtained through the Internet; the operation and maintenance vehicles are automatically recorded at each factory station The actual distance data between the two stations can be automatically obtained from the running trajectory data between the two stations; by automatically recording the distance between the operation and maintenance vehicles between the stations under the current weather conditions (such as rain and snow, the road is easy to slippery and affects the speed of the vehicle) The road condition data can be obtained from the distance data and the time spent; the new real-time effective MTBF data can be obtained by calculating the original MTBF data provided by the station equipment manufacturer and the actual operation of the type o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap