Handle unit

A technology of components and receiving parts, applied in the field of grasping units, can solve problems such as damage, achieve the effects of reducing complexity, simple and reliable connection, and improving configuration possibilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

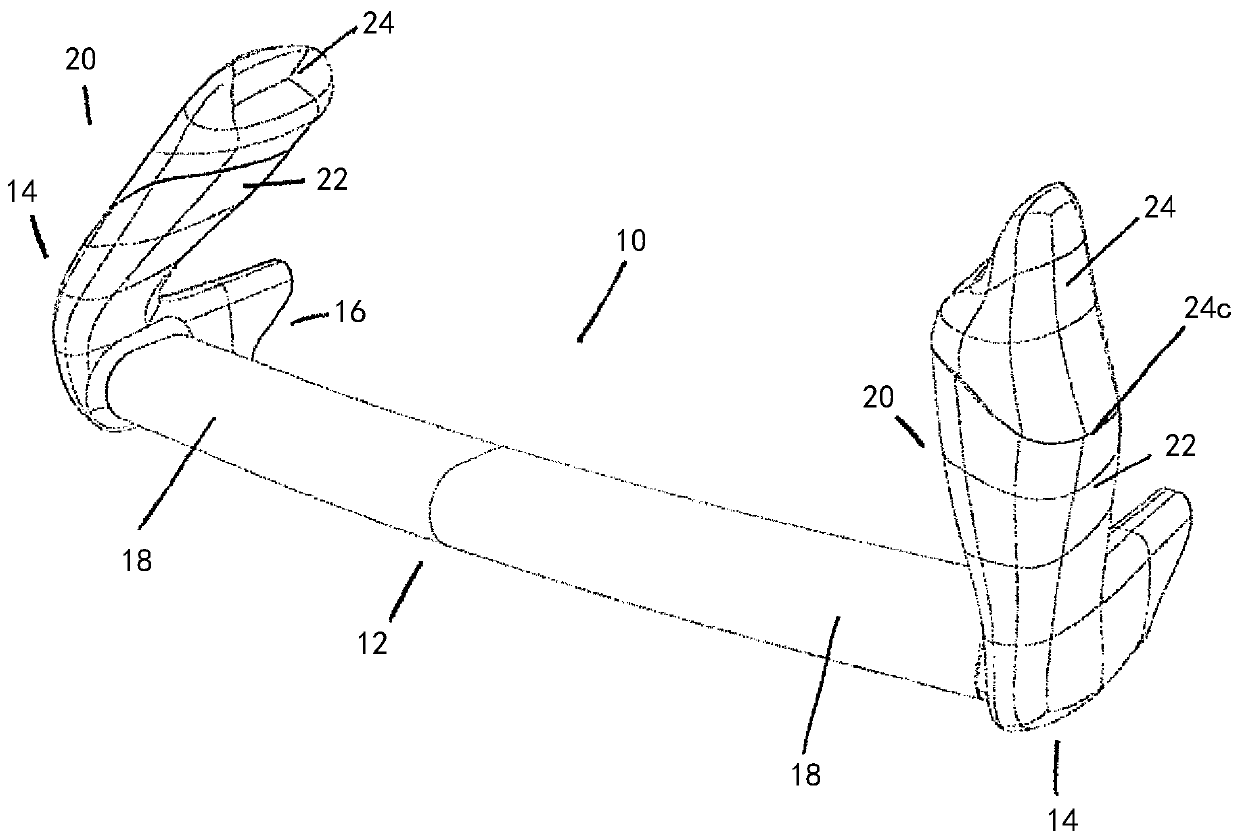

[0036] figure 1 An exemplary embodiment of the handle unit 20 according to the invention for moving the handle unit 10 is shown in perspective.

[0037] The sliding handle unit 10 has a cross brace 12 , which is here embodied as a transverse rod.

[0038] However, the cross brace 12 can also have a central part 13' and two gripping sections 18' separated from each other by the central part 13' (see image 3 ).

[0039] However, the cross brace 12 can also have a coin deposit system, as disclosed for example in EP 0 985 200 B1.

[0040] Such as figure 1 As shown, in the assembled state, the sliding handle unit 10 furthermore has an end part 14 at each end of the cross strut 12 , which are configured identically to each other in a mirror-inverted manner.

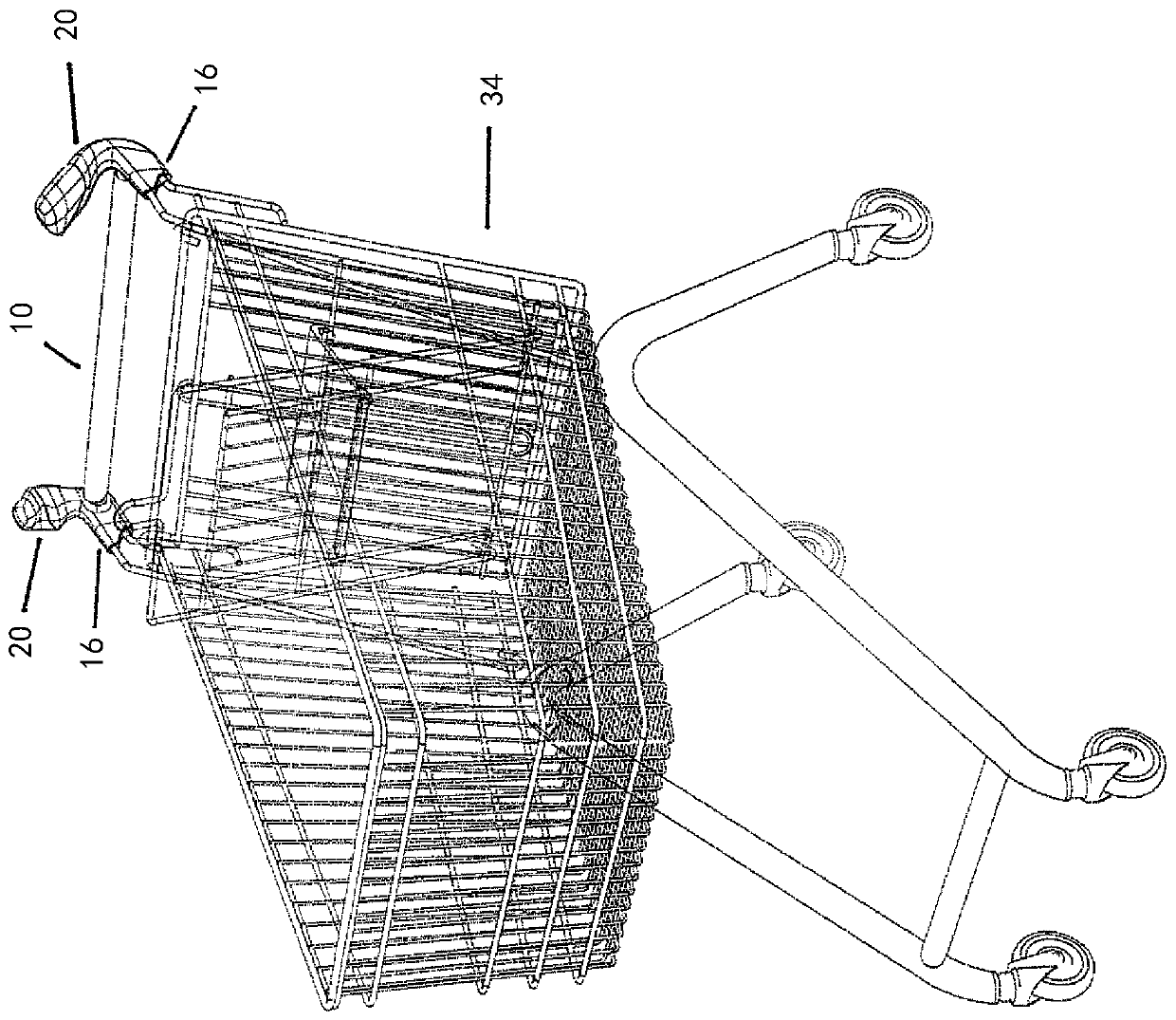

[0041] The end piece 14 has a fixing device 16 for fixing the end piece 14 on a manually movable transport trolley 34 (see figure 2 ).

[0042] Such a transport trolley 34 can be a shopping cart or a transport trolley for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com