Range hood

A technology of range hood and motor is applied in the fields of removing oil fume, household heating, space heating and ventilation details. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

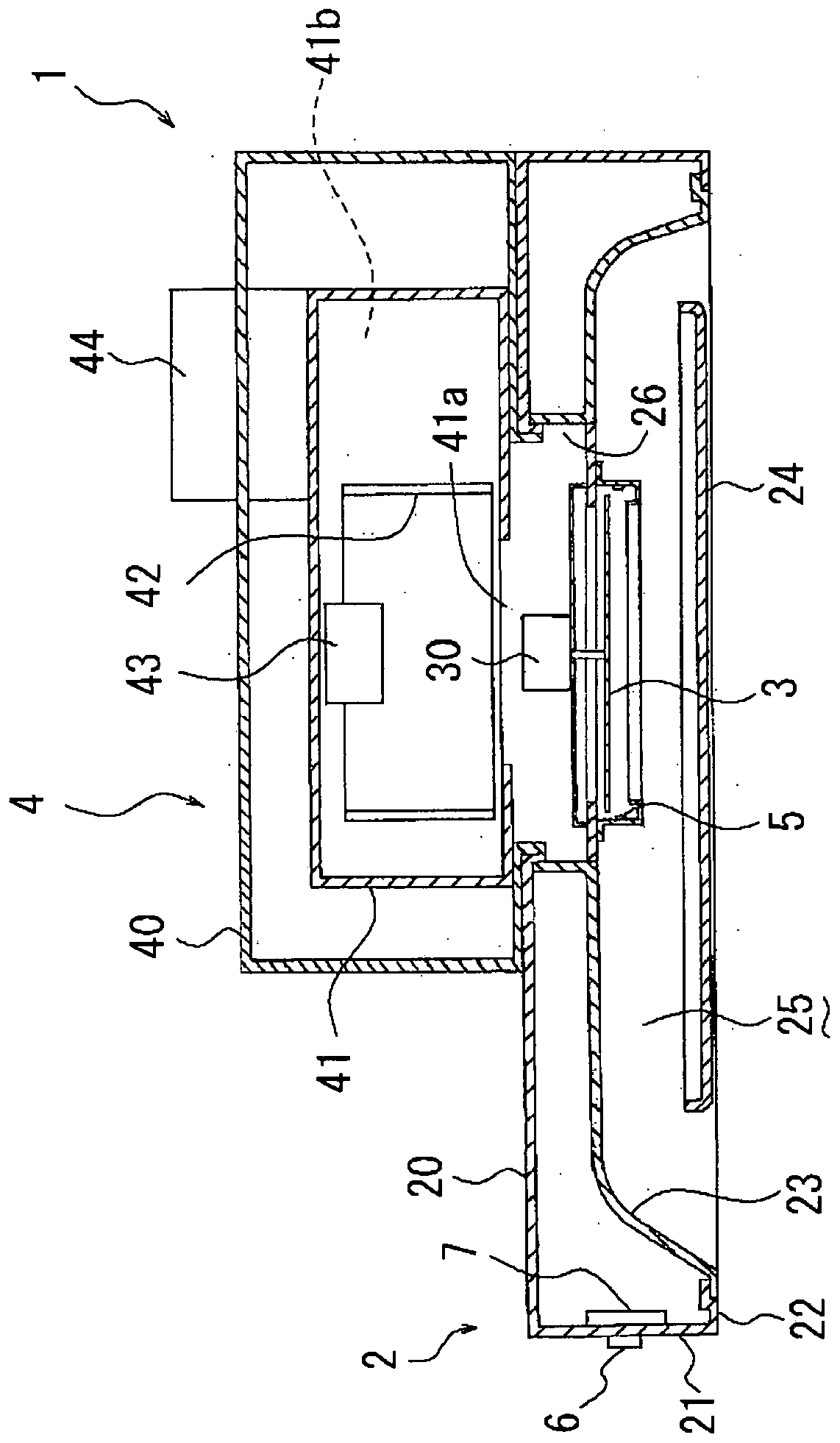

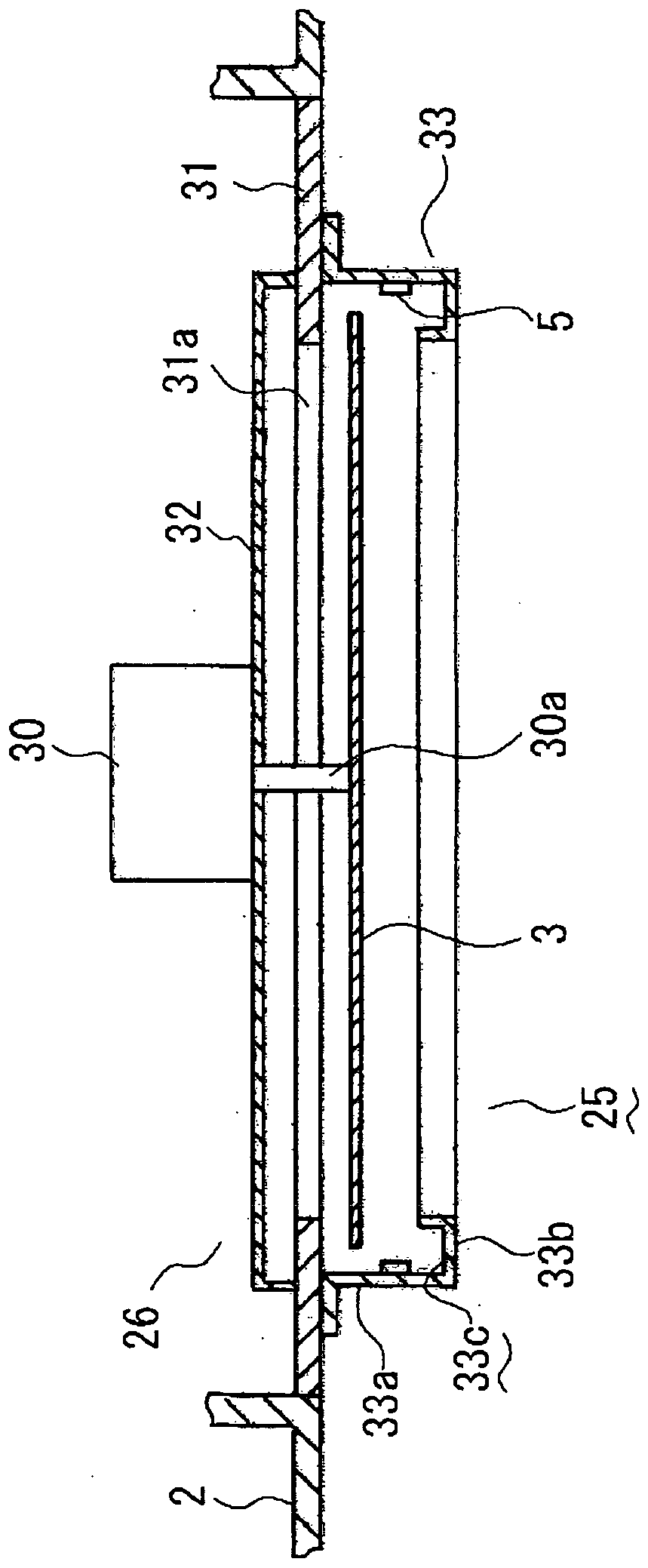

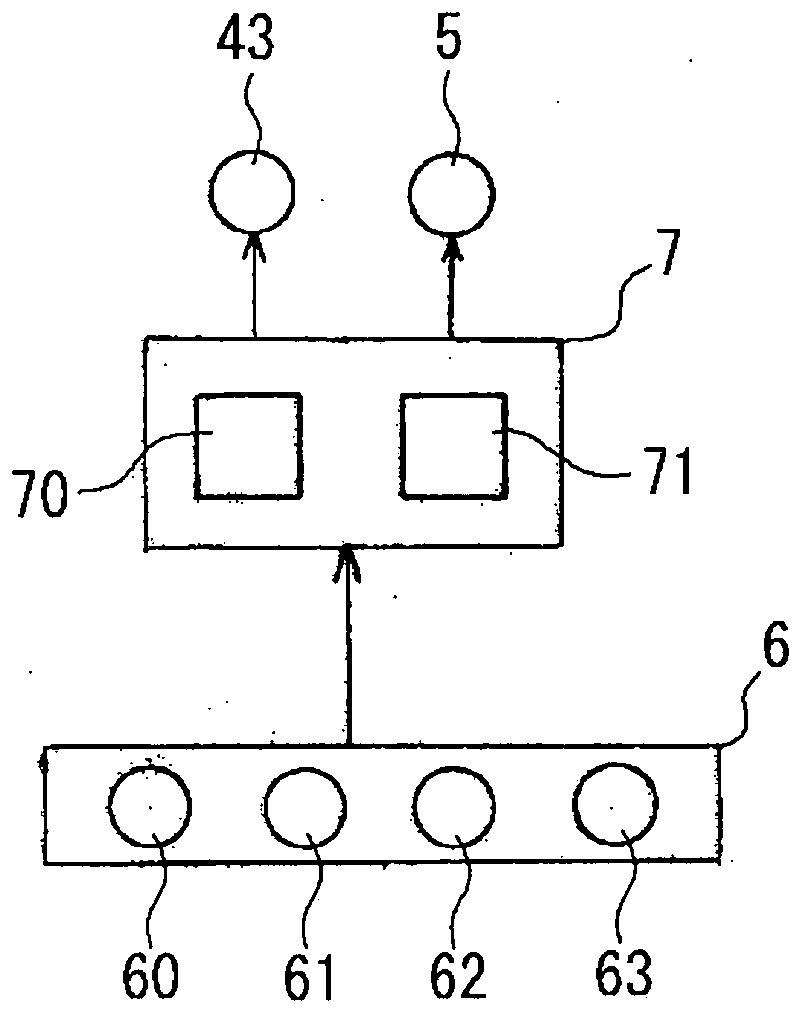

[0037] refer to figure 1 , figure 2 and image 3 The first embodiment of the present invention will be described.

[0038] figure 1 is a sectional view of the range hood, figure 2 It is an enlarged view of the filter attachment part, image 3 It is an explanatory diagram of the operation operation unit and the control unit.

[0039] The range hood 1 includes a cover 2 , a filter 3 , a blower 4 and an ultraviolet light source 5 .

[0040] The cover 2 is formed in a low rectangular box shape with a top panel 20 , a peripheral panel 21 and a lower panel 22 . The lower surface plate 22 has a recessed portion 23 recessed toward the top plate 20 , and a rectifying plate 24 is mounted in the recessed portion 23 , and a flow path 25 is formed by the rectifying plate 24 and the recessed portion 23 . The lower portion of the flow path 25 is opened to the lower side of the cover 2 , and the upper portion of the flow path 25 is opened to the upper side of the cover 2 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com