Energy-saving and reliable dust collecting pipe network system

A dust collection tube, a reliable technology, applied in the direction of dust removal, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of dust accumulation, high energy consumption of the dust collection system, and many safety hazards, and achieve high dust collection efficiency , improve efficiency, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the present invention is not limited in any way. Any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

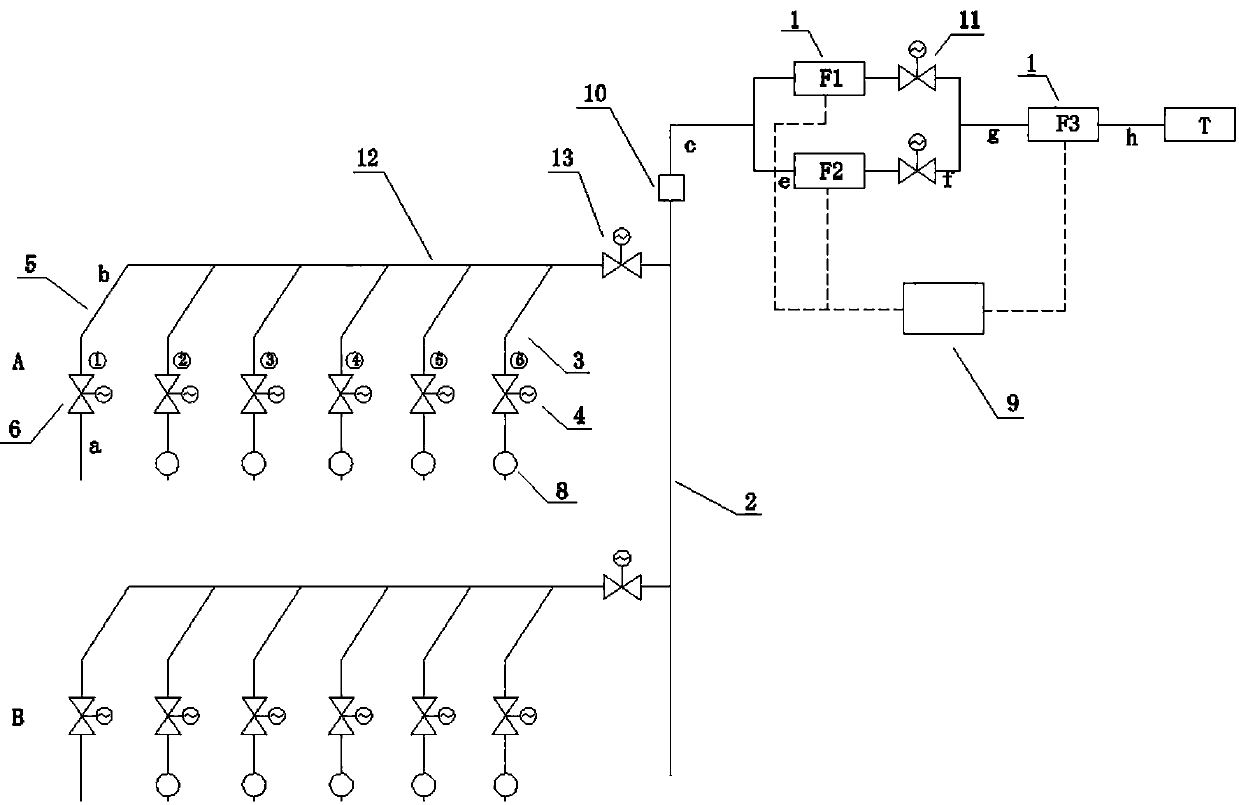

[0009] Such as figure 1 As shown, the present invention includes a dust removal fan 1, a dust collection main pipe 2, a dust collection branch pipe 3, and a valve I4. The outlet end of the dust collection main pipe 2 communicates with the air inlet of the dust removal fan 1. At least two dust collection branch pipes 3, valve I4 is installed on the dust collection branch pipe 3, the dust collection branch pipe 3 is used to suck the dust-laden gas to be captured, and the dust collection main pipe 2 is also connected with a clean air Tube 5 is used for suction of air.

[0010] The present invention also includes a controller, the clean air pipe 5 is equipped with a valve ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap