Cross main machine and grinding filing machine

A technology of cross and main engine, which is applied in the direction of grinding machines, grinding machine parts, grinding/polishing equipment, etc. It can solve the problems that the column bears a large bending moment and cannot move the grinding head in multiple directions, so as to meet the requirements of fast lifting of workpieces and improve flexibility. performance and bending moment improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

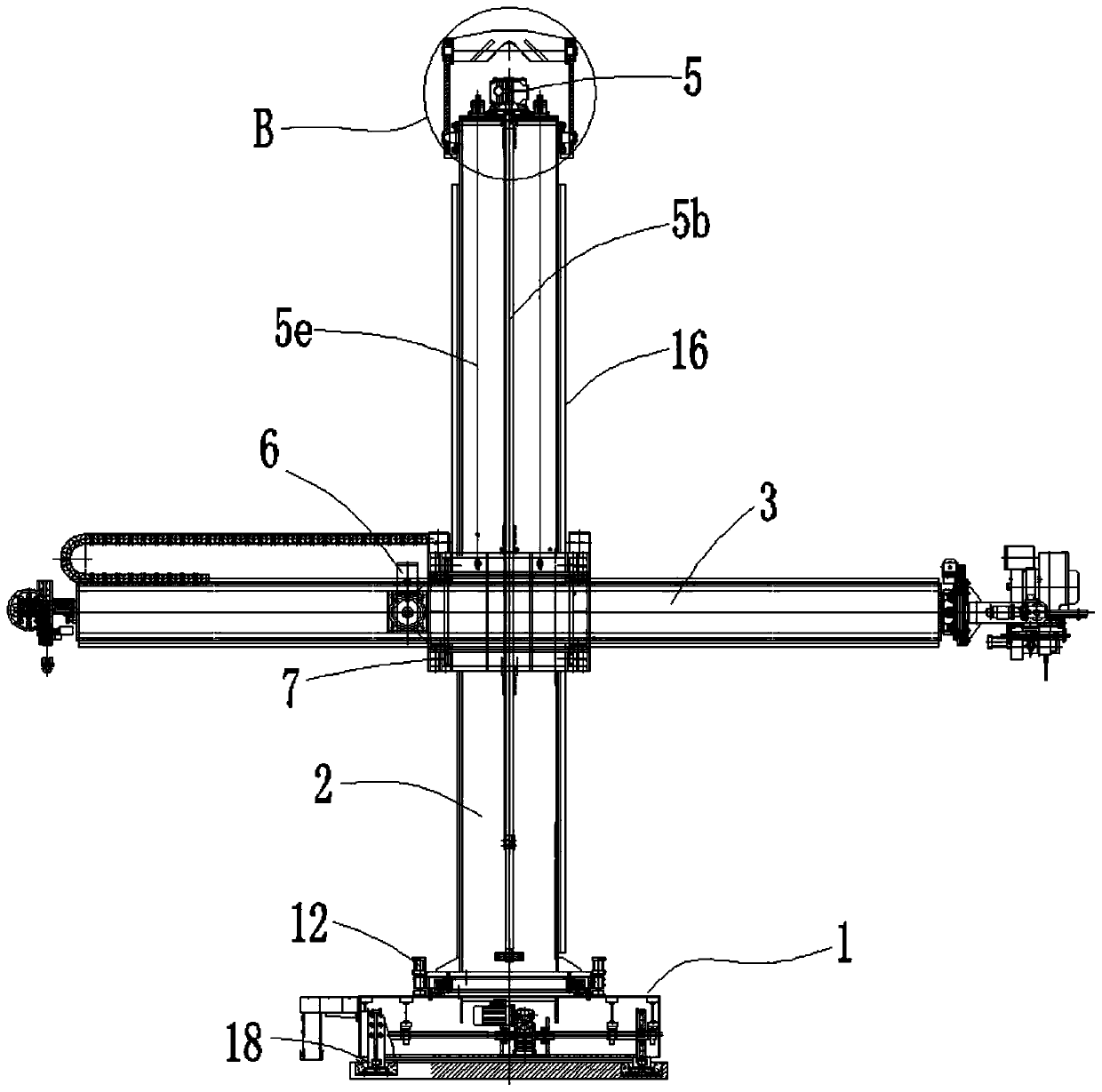

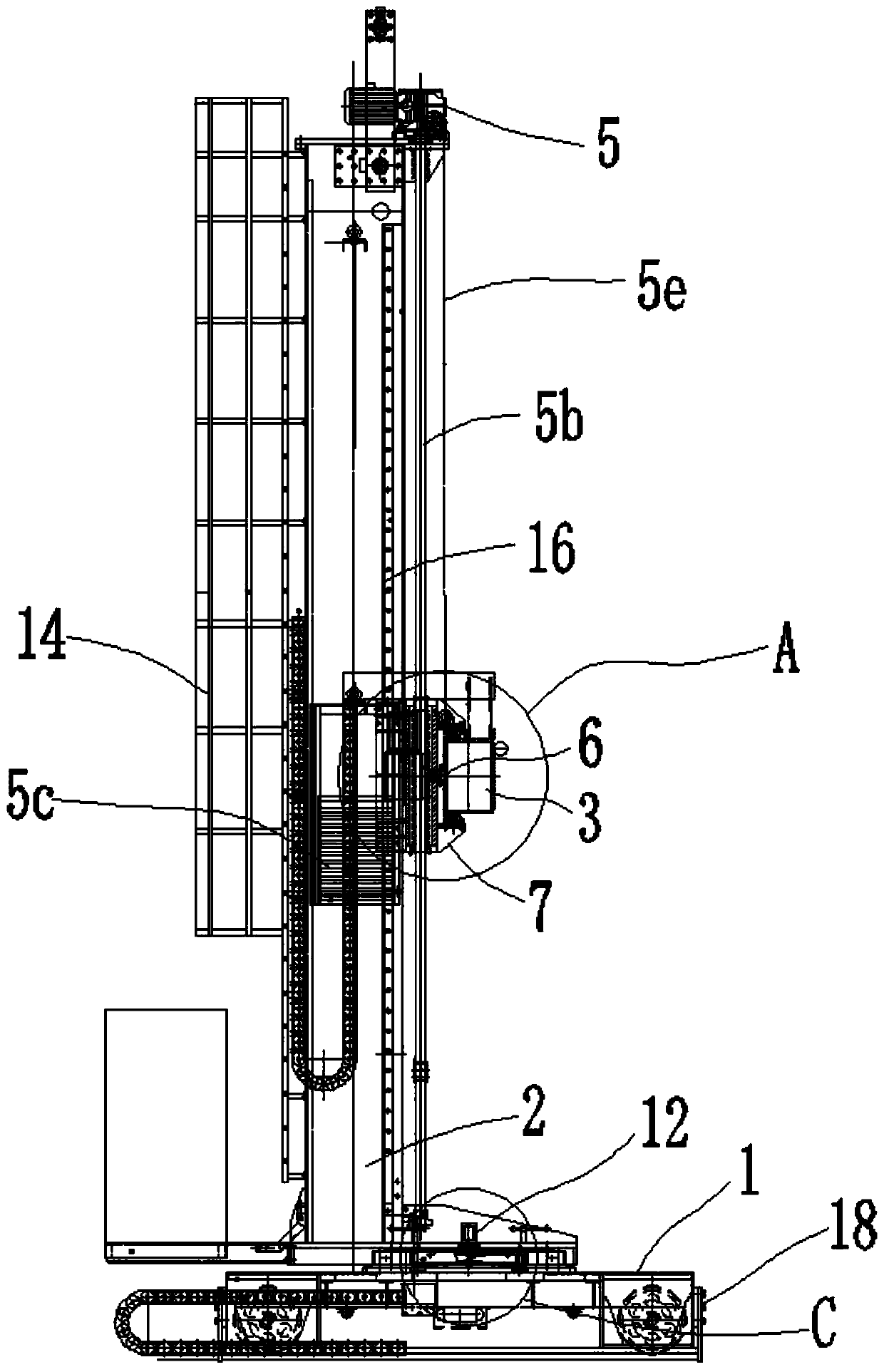

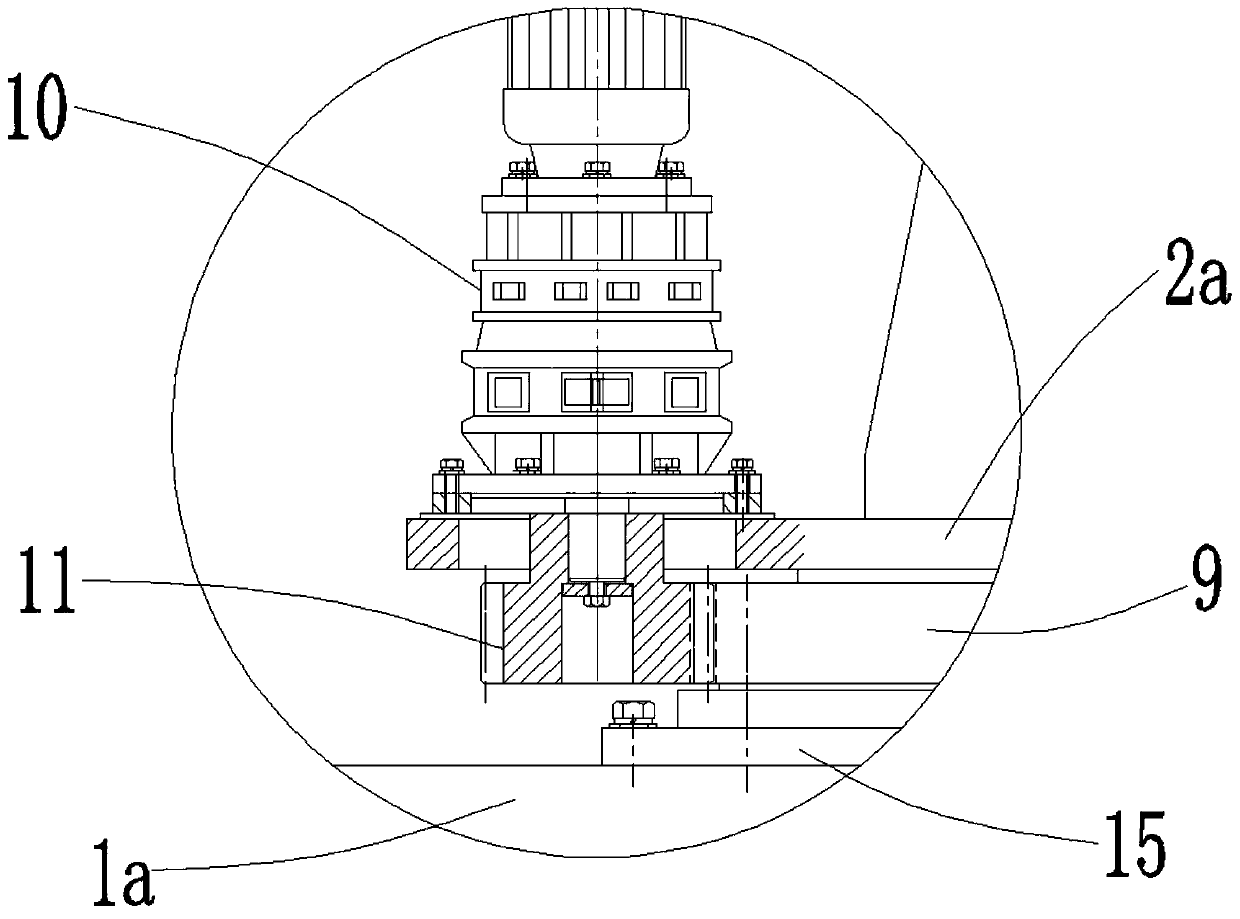

[0058] The cross host has the advantages of stable structure, stable movement and high precision, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, it is specially set to the following structure:

[0059] It includes an operating machine trolley 1, a column 2, a cross beam 3, an electric slewing mechanism, a lifting mechanism 5, a traverse mechanism 6, and a sliding plate 7.

[0060] The manipulator trolley 1 is a super-heavy walking trolley, which is used to carry components connected to it and to realize linear travel in the X direction. The operating machine trolley 1 mainly includes a trolley base 1a, a traveling geared motor 1b installed on the trolley base 1a, a traveling wheel 1c that is connected to the traveling geared motor 1b through a coupling, and the operating machine trolley 1 passes through the traveling wheel 1c is installed on a pre-laid walking track, which provides horizontal guidance for the X axis.

[0061] An ele...

Embodiment 2

[0075] This embodiment is further improved on the basis of the above embodiments, and particularly adopts the following configuration structure:

[0076] A number of anti-overturning structures 18 are fixedly installed at the side plates of the trolley base 1a of the operating machine trolley 1 by bolts, and the anti-overturning structures 18 are located above the walking track.

[0077] Specifically, the anti-overturning structure 18 mainly includes two anti-roll plates 18a that are integrally vertical plates. The bottom end of the anti-roll plate 18a has an escape groove for avoiding the walking track, so that the entirety is a vertical plate with a hook at the bottom. The anti-roll plate 18a is fixedly connected to the side plate of the trolley base 1a by bolts. There is a gap between the two anti-roll plates 18a in a single anti-roll structure 18, and the avoidance grooves of the two anti-roll plates 18a are arranged oppositely to form a T-shaped groove for clamping the limit w...

Embodiment 3

[0079] This embodiment also provides a file grinder on the basis of the above-mentioned embodiment, and particularly adopts the following arrangement structure:

[0080] Including the cross mainframe in embodiment 1, the grinding head of the grinding head and the welding head of the surfacing welding head are respectively fixedly installed at the two ends of the beam 3. After installing the grinding head of the grinding head machine on the cross host, the grinding head can move smoothly and stably in multiple directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com