Vacuum embossing production technology for TPE artificial leather

A production process, vacuum embossing machine technology, applied in the direction of layered products, lamination, lamination equipment, etc., can solve the problems that TPE materials cannot achieve vacuum embossing effect, time-consuming, high cost, etc., to achieve low cost, High foaming ratio, good degradable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

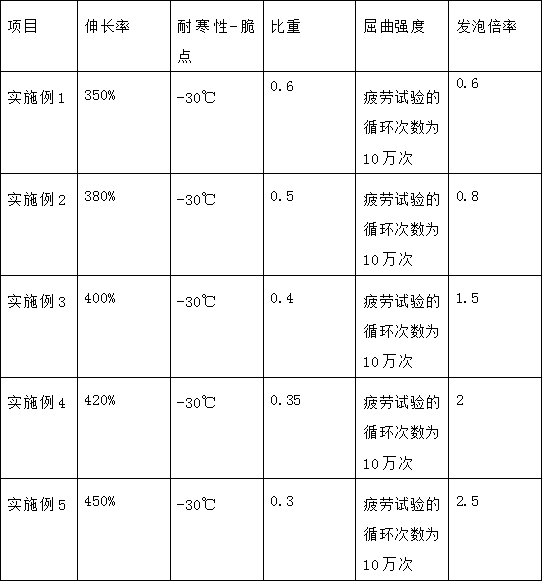

Examples

Embodiment 1

[0070] A vacuum embossing production process for TPE artificial leather, comprising the following steps:

[0071] TPE artificial leather preparation steps: prepare TPE artificial leather and set aside;

[0072] Absorbing step: use rubber wheel to press TPE artificial leather, make TPE artificial leather and vacuum absorbing roller flat and fit together, use vacuum absorbing machine to absorb TPE artificial leather, control parameters are as follows: power is 15KW, vacuum pressure is 650mmHG , The pumping capacity is 630 cubic meters per hour, the water temperature of the vacuum suction roller is controlled at 14°C, the surface temperature of the TPE artificial leather is controlled at 115°C after heating, and the speed of the vacuum suction machine is controlled at 10 m / min.

[0073] The TPE artificial leather includes a base fabric, and the upper surface of the base fabric is sequentially provided with a TPE base material layer and a TPE fabric layer; the TPE base material la...

Embodiment 2

[0089] A vacuum embossing production process for TPE artificial leather, comprising the following steps:

[0090] TPE artificial leather preparation steps: prepare TPE artificial leather and set aside;

[0091] Absorbing step: use rubber wheel to press TPE artificial leather, make TPE artificial leather and vacuum absorbing roller flat and fit together, use vacuum absorbing machine to absorb TPE artificial leather, control parameters are as follows: power is 15KW, vacuum pressure is 650mmHG , The pumping capacity is 600 cubic meters per hour, the water temperature of the vacuum suction roller is controlled at 12°C, the surface temperature of the TPE artificial leather is controlled at 110°C after heating, and the speed of the vacuum suction machine is controlled at 10 m / min.

[0092] The TPE artificial leather includes a base fabric, and the upper surface of the base fabric is sequentially provided with a TPE base material layer and a TPE fabric layer; the TPE base material la...

Embodiment 3

[0107] A vacuum embossing production process for TPE artificial leather, comprising the following steps:

[0108] TPE artificial leather preparation steps: prepare TPE artificial leather and set aside;

[0109] Absorbing step: use rubber wheel to press TPE artificial leather, make TPE artificial leather and vacuum absorbing roller flat and fit together, use vacuum absorbing machine to absorb TPE artificial leather, control parameters are as follows: power is 15KW, vacuum pressure is 650mmHG , The pumping capacity is 660 cubic meters per hour, the water temperature of the vacuum suction roller is controlled at 16°C, the surface temperature of the TPE artificial leather is controlled at 120°C after heating, and the speed of the vacuum suction machine is controlled at 10 m / min.

[0110] The TPE artificial leather includes a base fabric, and the upper surface of the base fabric is sequentially provided with a TPE base material layer and a TPE fabric layer; the TPE base material la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com