A kind of TPE artificial leather and preparation method thereof

A technology of artificial leather and base material layer, applied in the field of artificial leather, can solve the problems of low efficiency, high cost and time-consuming, and achieve the effects of high efficiency, low cost and high foaming ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

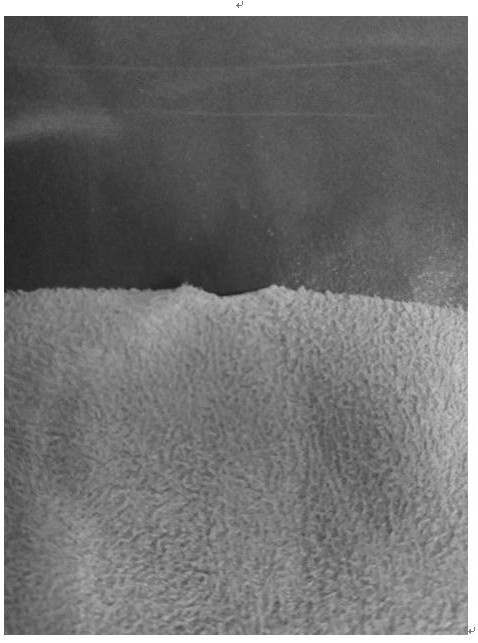

Image

Examples

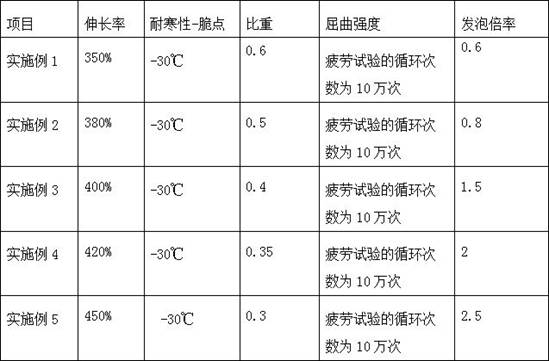

Embodiment 1

[0067] A TPE artificial leather, comprising a base cloth, the upper surface of the base cloth is sequentially provided with a TPE base material layer and a TPE fabric layer from bottom to top;

[0068] The TPE primer layer is prepared from the following components by mass percentage: SEBS 40.5%, ethylene-octene copolymer 25%, EVA 18%, calcium carbonate 15%, stearic acid 1%, oxidized Zinc 2.5%, PE wax 1%, vulcanizing agent 1%, foaming agent 3%, EVA masterbatch 3%;

[0069] The TPE fabric layer is prepared from the following components by mass percentage: SEBS 43.5%, ethylene-octene copolymer 25%, EVA 18%, calcium carbonate 15%, stearic acid 1%, zinc oxide 2.5%, PE wax 1%, curing agent 1%, EVA masterbatch 3%.

[0070] A preparation method of TPE artificial leather, comprising the following steps:

[0071] 1) TPE primer layer preparation steps:

[0072] 1-1) Add SEBS, ethylene-octene copolymer, EVA, calcium carbonate, stearic acid, zinc oxide, PE wax, vulcanizing agent, and EV...

Embodiment 2

[0085] A TPE artificial leather, comprising a base cloth, the upper surface of the base cloth is sequentially provided with a TPE base material layer and a TPE fabric layer from bottom to top;

[0086] The TPE primer layer is prepared from the following components by mass percentage: SEBS 41%, ethylene-octene copolymer 20%, EVA 15%, calcium carbonate 14%, stearic acid 0.5%, oxidation Zinc 3%, PE wax 1%, vulcanizing agent 1.5%, foaming agent 2%, EVA masterbatch 2%;

[0087] The TPE fabric layer is prepared from the following components by mass percentage: SEBS 45.5%, ethylene-octene copolymer 20%, EVA 15%, calcium carbonate 14%, stearic acid 0.5%, zinc oxide 2%, PE wax 0.5%, vulcanizing agent 0.5%, EVA masterbatch 2%;

[0088] A preparation method of TPE artificial leather, comprising the following steps:

[0089] 1) TPE primer layer preparation steps:

[0090]1-1) Add SEBS, ethylene-octene copolymer, EVA, calcium carbonate, stearic acid, zinc oxide, PE wax, vulcanizing agen...

Embodiment 3

[0102] A TPE artificial leather, comprising a base cloth, the upper surface of the base cloth is sequentially provided with a TPE base material layer and a TPE fabric layer from bottom to top;

[0103] The TPE primer layer is prepared from the following components by mass percentage: SEBS 42.5%, ethylene-octene copolymer 30%, EVA 10%, calcium carbonate 10%, stearic acid 0.5%, oxidized Zinc 2%, PE wax 0.5%, vulcanizing agent 0.5%, foaming agent 2%, EVA masterbatch 2%;

[0104] The TPE fabric layer is prepared from the following components by mass percentage: SEBS 44.5%, ethylene-octene copolymer 30%, EVA 10%, calcium carbonate 10%, stearic acid 0.5%, zinc oxide 2%, PE wax 0.5%, vulcanizing agent 0.5%, EVA masterbatch 2%.

[0105] A preparation method of TPE artificial leather, comprising the following steps:

[0106] 1) TPE primer layer preparation steps:

[0107] 1-1) Add SEBS, ethylene-octene copolymer, EVA, calcium carbonate, stearic acid, zinc oxide, PE wax, vulcanizing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com