Torque sensor assembly applied to hybrid engine

A torque sensor, hybrid technology, applied in the arrangement of multiple different prime movers of general power plants, hybrid vehicles, power plants, etc., can solve the problems of difficult engine torque and large error in calculation results, and achieve compensation Excellent efficiency and accurate signal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

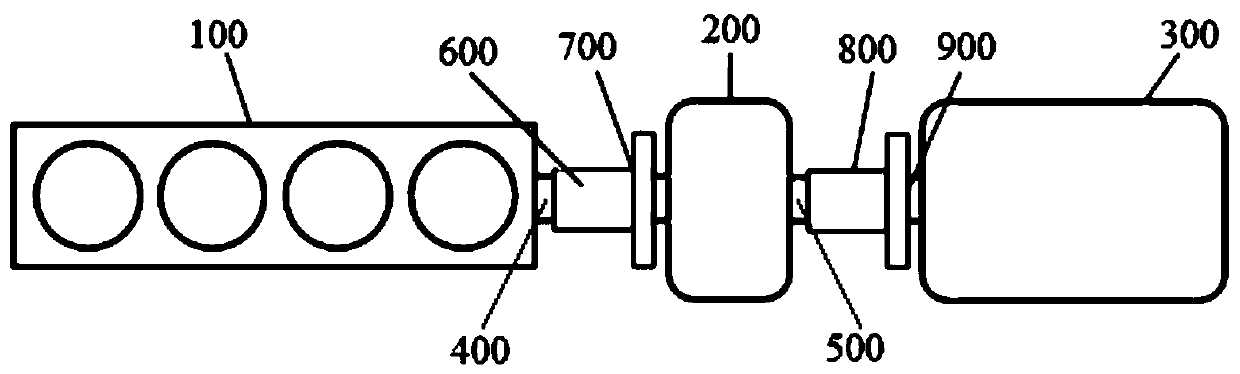

[0026] see figure 1 , is a schematic diagram of the overall structure of a torque sensor assembly applied to a hybrid engine according to an embodiment of the present invention, which mainly includes a coaxially connected engine 100 and an ISG (Integrated-Starter-Generator, integrated starter / power generation) motor 200 , the output terminal of the ISG motor 200 is connected to the load 300, and a first torque-rotation angle acquisition unit is arranged on the first connecting shaft 400 between the engine 100 and the ISG motor 200, for collecting the torque value and the real-time output of the engine 100 The speed value and the torque value are transmitted to the ISG motor 200; the ISG motor 200 is used as an energy storage component and is driven by electric energy to actively increase the ISG motor's own speed and torque t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com